A 4-axis CNC machine is an advanced computer numerical control (CNC) system that integrates three linear axes (X, Y, Z) with an additional rotational axis, typically the A-axis or B-axis, enabling complex multi-angle machining. This article provides a comprehensive overview of its features, technical specifications, operational mechanics, and applications across various industries, highlighting its role in enhancing precision and efficiency in manufacturing.

Core Features of 4-Axis CNC Machines

4-axis CNC machines are designed to handle intricate machining tasks by incorporating a rotational axis alongside the standard linear axes. Below are the key features that define their performance:

Axis Configuration and Motion

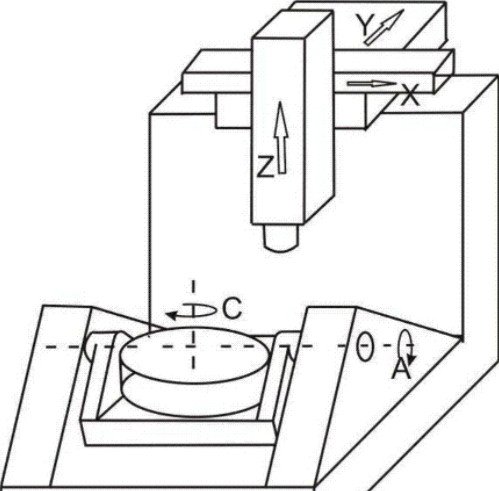

The machine operates with three linear axes—X (left to right), Y (front to back), and Z (up and down)—for translational movement, and one rotational axis, typically the A-axis (rotating around the X-axis) or B-axis (rotating around the Y-axis). The rotational axis allows for 360-degree rotation, enabling continuous or indexed machining. In continuous mode, the workpiece rotates while the tool cuts, ideal for cylindrical features like helical grooves. In indexed mode, the workpiece is rotated to a specific angle (e.g., 45° or 90°) and locked for machining, suitable for angled holes or slots.

Advanced models support 4-axis simultaneous interpolation (all axes moving together) or “3+1” mode, where the rotational axis is used for indexing while the linear axes perform the cutting. This flexibility enhances the machine’s ability to produce complex geometries with high precision (±0.005 mm).

Enhanced Machining Capabilities

Compared to 3-axis machines, 4-axis CNC machines can process parts with inclined surfaces, radial holes, or circumferential features, such as spiral grooves on a cylinder or angled slots on a shaft. The rotational axis reduces the need for multiple setups, minimizing repositioning errors and improving accuracy. For example, a part requiring features on multiple sides can be machined in a single setup, reducing setup time by 30–50% compared to 3-axis systems.

Technical Specifications

The following table outlines typical technical specifications for 4-axis CNC machines:

| Feature | Specification |

|---|---|

| Spindle Speed | 8,000–24,000 RPM |

| Spindle Power | 5.5–15 kW |

| A/B-Axis Rotation | 360° (continuous or indexed) |

| Table Size | 600 x 400 mm to 2000 x 1000 mm |

| Tool Magazine Capacity | 12–40 tools |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

Programming and Operation

Programming a 4-axis CNC machine requires advanced CAD/CAM software, such as UG (NX), PowerMill, or Mastercam, to generate toolpaths that account for the rotational axis. The G-code includes commands like G17-G19 for plane selection and G04 for dwell times to manage rotational movements. Operators must understand the interplay between linear and rotational axes to avoid tool interference, such as collisions between the tool and fixtures during rotation. This demands higher skill levels compared to 3-axis machining, often requiring specialized training.

Cost and Efficiency

4-axis CNC machines have a higher initial cost than 3-axis machines (approximately 1.5–2 times more, ranging from $50,000 to $150,000), but they are significantly less expensive than 5-axis machines (about 50–60% of the cost). The reduced setup time and improved precision make them cost-effective for medium to high-complexity parts, particularly in batch production where setup time savings translate to higher throughput.

Limitations of 4-Axis CNC Machines

While 4-axis CNC machines offer significant advantages, they have certain constraints:

- Single Rotational Axis: Limited to one rotational axis, they cannot handle complex spatial surfaces or undercuts requiring dual-axis rotation, such as turbine blades or impellers, which necessitate 5-axis machines.

- Programming Complexity: The inclusion of a rotational axis increases programming difficulty, requiring precise coordination to avoid errors like tool collisions.

- Maintenance Needs: The rotary axis adds mechanical complexity, requiring regular calibration and lubrication to maintain accuracy.

- Material Limitations: While versatile, certain high-hardness materials (e.g., titanium alloys) may require specialized tooling and higher spindle power, increasing operational costs.

Applications of 4-Axis CNC Machines

4-axis CNC machines are employed across diverse industries for their ability to produce complex parts with high precision and efficiency. Below are their primary applications:

Mold and Tool Manufacturing

In mold making, 4-axis CNC machines are used to create components like ejector pins, sliders, and angled mold surfaces for plastic injection molds. They excel at machining V-shaped grooves or inclined cutting edges for stamping dies, achieving surface finishes as fine as Ra 0.8 µm.

Aerospace and Automotive Components

Aerospace applications include machining inclined holes in aircraft structural parts, such as wing connectors, with tolerances of ±0.005 mm. In the automotive industry, 4-axis machines produce camshafts with eccentric grooves and radial oil holes, leveraging the A-axis for precise rotational indexing.

Medical Device Manufacturing

Medical applications involve precision milling of orthopedic implants, such as hip joint components with spherical surfaces and angled stems. Surgical tools, like multi-angle scalpels or bone drills, benefit from the machine’s ability to create complex blade geometries.

Hydraulic and Pneumatic Components

4-axis CNC machines manufacture hydraulic valve blocks with radial oil passages and inclined outlets. They also produce piston rods with helical grooves, using simultaneous A-axis and Z-axis movement to create spiral trajectories.

Craftsmanship and Precision Parts

In jewelry and metal craftsmanship, 4-axis machines engrave intricate patterns on cylindrical surfaces, such as decorative rings, with tolerances as low as ±0.01 mm. They are also used for motor rotors, machining balance grooves and commutator slots with precise angular positioning.

Comparison with 3-Axis and 5-Axis CNC Machines

The following table compares 3-axis, 4-axis, and 5-axis CNC machines to highlight their differences:

| Dimension | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

|---|---|---|---|

| Rotational Axes | None | 1 (A or B) | 2 (e.g., A + B/C) |

| Part Complexity | Flat/simple surfaces | Inclined/radial features | Complex spatial surfaces |

| Setup Frequency | Multiple (multi-face) | 1–2 (rotational adjustment) | 1 (full coverage) |

| Cost | Low ($20,000–$80,000) | Medium ($50,000–$150,000) | High ($100,000–$500,000) |

| Typical Applications | Flanges, panels | Camshafts, mold sliders | Turbine blades, impellers |

Operational Workflow

The operation of a 4-axis CNC machine follows a systematic process:

- Design Phase: A 3D model is created in CAD software, defining the part’s geometry and tolerances.

- Programming: CAM software generates toolpaths, incorporating A-axis rotations and G-code commands for precise control.

- Setup: The workpiece is secured on a rotary table or chuck, aligned with the rotational axis to ensure stability.

- Machining: The CNC controller executes the program, coordinating linear and rotational movements for continuous or indexed machining.

- Inspection: Post-machining checks using tools like coordinate measuring machines (CMM) verify accuracy and surface quality.

Choosing a 4-Axis CNC Machine

Selecting a 4-axis CNC machine involves evaluating several factors:

- Part Requirements: Ensure the machine supports the desired geometries, such as radial or inclined features.

- Material Compatibility: Verify spindle power and tooling suitability for materials like stainless steel or composites.

- Production Volume: High-volume tasks benefit from larger tool magazines and faster spindle speeds (e.g., 24,000 RPM).

- Software Support: Compatibility with industry-standard CAD/CAM systems ensures efficient programming.

- Budget Constraints: Balance initial costs with long-term savings from reduced setup times and improved precision.

Conclusion

4-axis CNC machines bridge the gap between 3-axis and 5-axis systems, offering a cost-effective solution for machining complex parts with inclined or radial features. Their ability to reduce setup times, enhance precision, and handle diverse materials makes them invaluable in industries like aerospace, automotive, medical, and mold manufacturing. While they require advanced programming skills and higher initial investment, their efficiency and versatility provide significant returns for medium to high-complexity manufacturing tasks. By understanding their features, limitations, and applications, manufacturers can optimize their use for precision and productivity.