Thermal spraying is a group of coating processes that deposit finely divided metallic or non-metallic materials in a molten or semi-molten state onto a substrate to form a protective or functional coating. This technology enhances surface properties such as wear resistance, corrosion protection, thermal insulation, and electrical conductivity. Used across industries like aerospace, automotive, and biomedical, thermal spraying offers a versatile solution for improving component durability and performance. This article provides a detailed, technical overview of thermal spraying, including its principles, processes, key parameters, and applications.

Definition and Principles of Thermal Spraying

Thermal spraying involves heating a feedstock material—typically in the form of powder, wire, or rod—until it reaches a molten or semi-molten state. The material is then accelerated by a gas stream and projected onto a prepared substrate, where it rapidly solidifies to form a coating. The coating is built up by the accumulation of flattened particles, known as splats, which create a lamellar microstructure. The process relies on a combination of thermal energy to melt the material and kinetic energy to propel it onto the substrate. Unlike welding, thermal spraying is primarily a mechanical bonding process, with some diffusion bonding in specific cases. The substrate typically experiences minimal heating, often below 50°C, which prevents thermal distortion or metallurgical changes.

The coating materials can include metals, alloys, ceramics, polymers, and composites, allowing for tailored surface properties. The process is line-of-sight, meaning the spray must directly reach the substrate surface, which can limit its application on complex geometries. Thermal spraying is distinguished by its ability to deposit thick coatings, ranging from 20 micrometers to several millimeters, at high deposition rates compared to other coating methods like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

Types of Thermal Spray Processes

Thermal spraying encompasses several processes, each utilizing different heat sources and feedstock delivery methods. The choice of process depends on the coating material, desired properties, and application requirements. Below are the primary thermal spray processes:

Flame Spraying

Flame spraying uses a combustion flame, typically fueled by acetylene or propane combined with oxygen, to melt the feedstock. The material, in powder, wire, or rod form, is fed into the flame, reaching temperatures of 4,600–5,200°F (2,540–2,870°C). Compressed air or gas propels the molten particles onto the substrate at velocities of 80–300 m/s. This process is cost-effective and suitable for stress-sensitive substrates but produces coatings with higher porosity (up to 20%) and lower adhesion strength compared to other methods.

Electric Arc Spraying

Electric arc spraying involves feeding two electrically conductive wires, charged with opposite polarities, into a spray gun. An arc forms at the wire tips, melting the material at temperatures up to 7,000°C. Compressed air atomizes the molten material and propels it onto the substrate at velocities of 100–150 m/s. Commonly used for metallic coatings like aluminum or zinc, this process is economical and ideal for large-scale applications such as corrosion protection of steel structures. However, it is limited to conductive wire materials.

Plasma Spraying

Plasma spraying employs a plasma jet, generated by an arc between electrodes in a torch, to heat the feedstock. The plasma, formed from gases like argon, helium, hydrogen, or nitrogen, reaches temperatures exceeding 15,000°C. Powder particles, typically 10–100 µm in size, are injected into the plasma, melted, and accelerated at velocities of 100–800 m/s. Plasma spraying is highly versatile, capable of depositing refractory materials like oxides and carbides. Vacuum plasma spraying, conducted in a controlled low-pressure environment, minimizes oxidation and is used for applications like automotive components.

High-Velocity Oxy-Fuel (HVOF) Spraying

HVOF spraying uses a high-pressure combustion of fuel (e.g., kerosene, propane) and oxygen in a chamber, producing a supersonic gas stream through a de Laval nozzle. The gas reaches velocities up to 2,000 m/s and temperatures of 2,300–3,000°C. Powder feedstock, typically 10–50 µm, is injected axially or radially, achieving high particle velocities (500–800 m/s). HVOF produces dense coatings with low porosity (<1%) and high bond strength (up to 80 MPa), making it ideal for wear-resistant coatings like WC-Co.

Cold Spraying

Cold spraying is unique as it does not melt the feedstock. Instead, powder particles are accelerated to supersonic speeds (500–1,200 m/s) using a preheated gas (200–1,100°C) through a de Laval nozzle. The high kinetic energy causes plastic deformation upon impact, forming a solid-state coating. High-pressure cold spraying (HPCS, up to 40 bar) and low-pressure cold spraying (LPCS, up to 10 bar) are the two variants. Cold spraying minimizes oxidation and is suitable for ductile materials like copper or titanium, producing coatings with low porosity and high adhesion.

Key Process Parameters

The performance of thermal spray coatings depends on precise control of process parameters. These parameters influence coating properties such as adhesion, porosity, hardness, and microstructure. The following table summarizes critical parameters for major thermal spray processes:

| Process | Key Parameters | Typical Values |

|---|---|---|

| Flame Spraying | Fuel-oxygen ratio, gas flow rate, standoff distance, powder feed rate | Fuel-oxygen ratio: 1:1–1.2:1; Gas flow: 50–100 L/min; Standoff: 100–200 mm; Feed rate: 0.5–1 g/s |

| Electric Arc Spraying | Voltage, current, air pressure, wire feed rate | Voltage: 20–40 V; Current: 100–300 A; Air pressure: 4–7 bar; Feed rate: 1–5 m/min |

| Plasma Spraying | Plasma power, gas composition, gas flow, standoff distance, powder feed rate | Power: 20–80 kW; Gas flow: 40–100 L/min (Ar/H2); Standoff: 50–150 mm; Feed rate: 20–100 g/min |

| HVOF Spraying | Fuel-oxygen ratio, combustion pressure, nozzle geometry, powder feed rate | Fuel-oxygen ratio: 1:2–1:4; Pressure: 5–10 bar; Standoff: 200–400 mm; Feed rate: 50–120 g/min |

| Cold Spraying | Gas pressure, gas temperature, nozzle geometry, powder feed rate | Pressure: 10–40 bar (HPCS); Temperature: 200–1,100°C; Standoff: 10–50 mm; Feed rate: 10–50 g/min |

These parameters must be optimized based on the feedstock material and desired coating properties. For example, in plasma spraying, increasing the plasma power enhances particle melting but may increase porosity if not balanced with gas flow. In HVOF, higher combustion pressure improves particle velocity, reducing porosity and enhancing bond strength.

Coating Characteristics and Evaluation

Thermally sprayed coatings exhibit a lamellar microstructure, with splats forming successive layers. Key characteristics include:

- Adhesion Strength: Typically 10–70 MPa, depending on the process and substrate preparation. HVOF and cold spraying achieve higher bond strengths due to high particle velocities.

- Porosity: Varies from <0.5% (HVOF, cold spraying) to 20% (flame spraying). Porosity affects corrosion resistance and mechanical properties.

- Hardness: Depends on the coating material (e.g., WC-Co coatings reach 800–1,200 HV). Hardness enhances wear resistance.

- Thickness: Ranges from 20 µm to several millimeters, tailored to the application.

- Surface Roughness: As-sprayed coatings have Ra values of 3–40 µm, often requiring post-processing for smooth surfaces.

Coating quality is evaluated using metrics such as bond strength (ASTM C633), porosity (image analysis), hardness (Vickers or Rockwell), and surface roughness (profilometry). Post-treatments like sealing with waxes or epoxies or remelting with laser beams can reduce porosity and improve performance.

Applications of Thermal Spraying

Thermal spraying is widely used across industries to enhance component performance. Key applications include:

Aerospace

Thermal barrier coatings (TBCs), such as yttria-stabilized zirconia, are applied to turbine blades to withstand temperatures up to 1,200°C. HVOF-sprayed WC-Co coatings protect landing gear from wear.

Automotive

Plasma-sprayed ceramic coatings on aluminum wheel rims improve hardness and wear resistance. Cold spraying restores worn engine components with minimal thermal impact.

Biomedical

Plasma-sprayed hydroxyapatite (HA) coatings on orthopedic implants enhance osseointegration. Process parameters like powder feed rate and plasma power are optimized to achieve coatings with 5–10% porosity for bone ingrowth.

Steel Industry

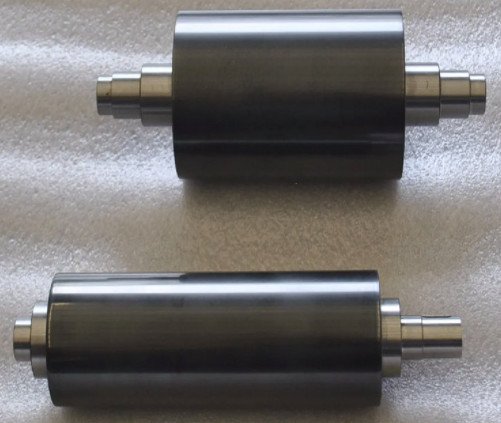

HVOF-sprayed WC-Co coatings on galvanizing line hardware resist zinc corrosion. Flame-sprayed coatings protect furnace components from high-temperature oxidation.

Electronics

Arc-sprayed copper coatings provide electrical conductivity on circuit board components. Plasma spraying deposits insulating ceramic layers for thermal management.

Limitations and Considerations

Thermal spraying has some constraints that must be addressed for optimal results:

- Line-of-Sight Limitation: The process requires direct access to the substrate, making it challenging for complex geometries or internal surfaces.

- Porosity and Oxide Inclusions: High-temperature processes like flame and plasma spraying can introduce porosity (up to 20%) and oxide layers, reducing corrosion resistance. Cold spraying and HVOF minimize these issues.

- Substrate Preparation: Surfaces must be cleaned and roughened (e.g., grit blasting to 2–6 µm Ra) to ensure adhesion, adding time and cost.

- Material Limitations: Materials that decompose upon melting, such as some polymers, are unsuitable for high-temperature processes.

These limitations can be mitigated through careful process selection and parameter optimization. For example, vacuum plasma spraying reduces oxidation, while cold spraying avoids thermal degradation of sensitive materials.

Conclusion

Thermal spraying is a versatile and widely adopted coating technology that enhances the durability and functionality of components across multiple industries. By understanding the principles, processes, and key parameters—such as fuel-oxygen ratios, plasma power, and particle velocities—engineers can tailor coatings to meet specific requirements. Processes like flame spraying, electric arc spraying, plasma spraying, HVOF, and cold spraying each offer unique advantages, from cost-effectiveness to high-density coatings. Despite limitations like line-of-sight constraints and porosity, thermal spraying remains a critical tool for surface engineering, with applications ranging from aerospace to biomedical implants.

FAQ about thermal spraying

What is thermal spraying?

Thermal spraying is a process that uses high heat and carrier gases to melt powdered or wire material and apply it to a surface. It melts the feedstock (such as metal, ceramic, or composite materials in the form of powder, wire, or rod) with a heat source like an electric arc, flame, or plasma, and then propels the molten or semi - molten particles onto a substrate surface to form a coating.

What are the different types of thermal spray equipment?

Arc spray: Uses an electric arc to melt wires and compressed air to spray the molten metal.

Flame spray: Employs an oxy - fuel flame to melt wires, and can also be used for powders or ceramic rods in some cases.

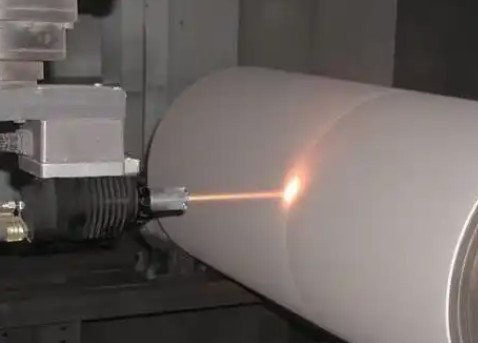

Laser cladding: A “hard - facing” process to apply a dense, metallurgically bonded coating.

Plasma spray: Powder particles are injected into the plasma jet emerging from the nozzle, soften, and strike the surface at high velocity.

High velocity oxygen fuel (HVOF): Used to apply very dense, strongly adhered coatings, often as a hard chrome replacement.

Why should I use thermal spraying in place of other coatings?

Thermal sprayed coatings have many advantages. Components can be used immediately after spraying. Compared to paint, they are less prone to damage during shipping and handling. They are cost - effective for long - term corrosion protection in harsh environments like the sea and salty air.

What is the difference between HVAf and HVOF?

The main difference lies in the combustion gas used. HVOF uses an oxy - fuel mixture, while HVAf uses compressed air and propane. HVAf has better coating performance in terms of ductility, bond strength, and hardness, and can spray thinner coatings with a smoother as - sprayed roughness.

At what temperature is thermal spray applied?

Thermal spray processes have different application temperatures, mostly in the range of 3,560 °F to 7,000 °F, except for plasma thermal spray, which ranges from 12,000 °F to 35,500 °F.