Artificial Intelligence (AI) has become a transformative force in 3D printing, also known as additive manufacturing (AM), by improving efficiency, precision, and automation across various stages of the process. This article provides a detailed examination of how AI technologies, particularly machine learning (ML) and computer vision, are applied to 3D printing workflows. It focuses on technical implementations, specific parameters, and system-level benefits, offering a structured and professional perspective for engineers, researchers, and industry professionals.

AI-Driven Design Optimization

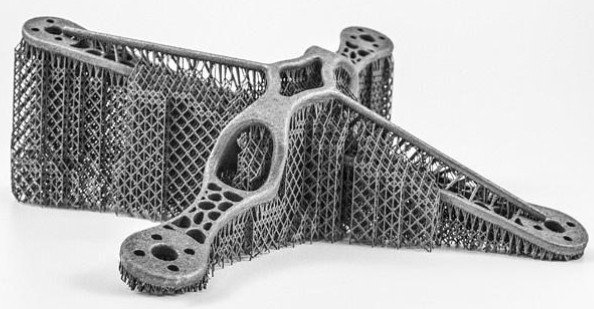

AI enhances the design phase of 3D printing by automating the creation and optimization of complex geometries. Machine learning algorithms, such as generative design models, analyze input parameters like material properties, structural requirements, and manufacturing constraints to produce optimized designs. These algorithms use iterative processes to evaluate thousands of design iterations, ensuring minimal material usage while maintaining structural integrity.

For example, in topology optimization, AI models solve partial differential equations to determine the optimal material distribution within a given design space. A typical setup might involve a finite element analysis (FEA) model with parameters such as maximum stress (e.g., 500 MPa for a titanium alloy), load conditions (e.g., 10 kN compressive force), and volume reduction targets (e.g., 30% less material). The AI then generates a lattice structure that meets these criteria, often reducing weight by 20-40% compared to traditional designs.

AI also automates the conversion of scanned data into printable 3D models. Tools like Nvidia Instant NeRF use neural networks to reconstruct 3D models from 2D images or CT/MRI scans. These systems process image data with resolutions up to 512x512 pixels, achieving a reconstruction accuracy of 95% or higher in under 10 seconds for a typical 10 MB dataset.

Material Selection and Parameter Tuning

Selecting appropriate materials and tuning printing parameters are critical for achieving high-quality 3D-printed parts. AI systems, particularly those using supervised learning, analyze historical printing data to recommend optimal material and parameter combinations. For instance, in laser powder bed fusion (LPBF), AI models correlate parameters like laser power (200-400 W), scan speed (500-1500 mm/s), and layer thickness (20-50 µm) with outcomes such as porosity (target <1%) and mechanical strength (e.g., ultimate tensile strength of 900 MPa for Ti6Al4V).

A practical example involves random forest models, which achieve prediction accuracies of 96-98% for properties like compressive strength in 3D-printed concrete. These models use input features such as cement-to-sand ratio (e.g., 1:2), water content (e.g., 0.4 water-cement ratio), and printing speed (e.g., 100 mm/s). By training on datasets of 500+ print jobs, AI can predict optimal settings, reducing trial-and-error by up to 80%.

| Parameter | Range | Impact |

|---|---|---|

| Laser Power | 200-400 W | Affects melt pool size and depth |

| Scan Speed | 500-1500 mm/s | Influences cooling rate and porosity |

| Layer Thickness | 20-50 µm | Determines resolution and build time |

In-Situ Process Monitoring

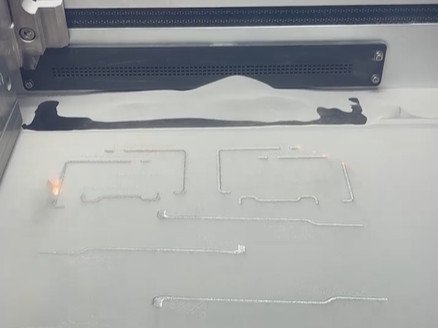

In-situ monitoring ensures real-time quality control during 3D printing. AI-powered computer vision systems, often using convolutional neural networks (CNNs), analyze data from cameras and sensors to detect defects like cracks, warping, or layer misalignment. For example, a dual-camera setup with 1080p resolution and 30 fps can monitor the print bed, calculating material thickness by measuring light transmission with an accuracy of ±0.01 mm.

In a specific case, a CNN model trained on 10,000 images of LPBF prints achieved a defect detection accuracy of 94% based on metrics like recall and F1 score. The system processes vibrational signals from accelerometers placed near the printer nozzle, detecting anomalies at 71% higher sensitivity compared to frame-mounted sensors. This allows real-time adjustments, such as reducing print speed by 10% (e.g., from 300 mm/s to 270 mm/s) to correct detected errors.

AI also enables closed-loop feedback systems. These systems use sensor data (e.g., temperature sensors reading 200-300°C for FDM printers) to dynamically adjust parameters like feed rate or extruder temperature, ensuring consistent print quality. Such systems can reduce material waste by up to 15% and energy consumption by 10-20%.

Predictive Maintenance for 3D Printers

AI-driven predictive maintenance minimizes printer downtime by analyzing real-time performance data. Platforms like 3YOURMIND use ML to monitor components such as extruders (lifespan ~2,000 hours) and motors, predicting failures based on metrics like vibration frequency (e.g., 50-100 Hz indicating wear). By scheduling maintenance only when needed, these systems reduce downtime by 25% and maintenance costs by 15-20%.

For example, a deep neural network (DNN) model processes data from current, vibration, and sound sensors, achieving a fault prediction accuracy of 92%. This allows proactive replacement of parts like belts (failure threshold at 1,000 cycles) before they cause print failures, ensuring continuous operation in industrial settings.

Automation of Post-Processing

Post-processing, such as support removal and surface finishing, is often labor-intensive. AI automates these tasks by optimizing workflows. For instance, reinforcement learning algorithms determine the optimal sequence for removing support structures in metal 3D printing, reducing processing time by 30%. In direct metal laser sintering (DMLS), AI adjusts parameters like heat treatment temperature (e.g., 650°C for stress relief) and duration (e.g., 2 hours) to enhance surface quality (target roughness <2 µm).

AI also improves non-destructive testing (NDT) by analyzing X-ray or ultrasonic data to detect internal defects. A neural network trained on 5,000 X-ray images can identify voids with a diameter as small as 0.1 mm, achieving 90% accuracy and reducing inspection time by 40% compared to manual methods.

Challenges in Data Management

One significant limitation in AI-augmented 3D printing is the availability of high-quality, structured data. ML models require large datasets (e.g., 10,000+ print jobs) for training, but 3D printing data is often unstructured or incomplete. For example, variations in environmental conditions like humidity (40-60% ideal range) or temperature (20-25°C) can affect print outcomes but are rarely standardized across datasets. This complicates model training and reduces prediction accuracy by 10-15% in some cases.

Another issue is data privacy, particularly in medical applications. AI systems processing patient-specific data, such as CT scans with 512x512 pixel resolution, must comply with regulations like HIPAA, requiring secure data pipelines and encryption protocols (e.g., AES-256). These constraints increase implementation costs by 5-10%.

Applications in Biomedical Engineering

AI and 3D printing have significant applications in biomedical engineering, particularly in creating patient-specific organ models. AI processes medical imaging data (e.g., MRI with 1 mm slice thickness) to generate 3D models with 98% geometric accuracy. These models, printed using digital light processing (DLP) with 25 µm resolution, are used for preoperative planning, reducing surgery time by 15-20%.

For example, a neural network can segment a CT scan of a kidney in 5 minutes, compared to 30 minutes manually, and generate a printable model with a dimensional tolerance of ±0.05 mm. The resulting model, printed in photopolymer resin, mimics tissue properties with a Shore hardness of 70A, suitable for surgical simulation.

| Parameter | Value | Purpose |

|---|---|---|

| Image Resolution | 512x512 pixels | Ensures detailed model reconstruction |

| Print Resolution | 25 µm | Achieves high surface detail |

| Material Hardness | 70A (Shore) | Mimics soft tissue properties |

Integration with Manufacturing Execution Systems

AI integrates with Manufacturing Execution Systems (MES) to manage large-scale 3D printing operations. These systems coordinate multiple printers, optimizing schedules based on print time (e.g., 10 hours for a 200 mm³ part) and material availability (e.g., 5 kg of ABS filament). AI algorithms predict production bottlenecks, improving throughput by 20% in multi-printer setups.

For instance, an MES with AI integration can prioritize print jobs based on complexity, assigning high-resolution tasks (e.g., 50 µm layer height) to DLP printers and faster, lower-resolution tasks (e.g., 200 µm) to FDM printers. This ensures efficient resource allocation and reduces idle time by 15%.

Conclusion

The integration of AI into 3D printing enhances every stage of the process, from design optimization to post-processing. By leveraging machine learning, computer vision, and predictive analytics, AI achieves precise control over parameters, improves quality, and reduces waste. Specific applications, such as biomedical modeling and industrial automation, demonstrate the technology’s versatility. Despite challenges like data management and privacy, AI-driven 3D printing is poised to advance manufacturing efficiency and precision, offering a robust framework for modern production workflows.