Trial production is a critical phase in manufacturing, bridging the gap between product design and full-scale production. It involves producing a limited batch of products to validate manufacturing processes, assess product quality, and identify potential issues before mass production. This article provides a systematic, technical overview of trial production, focusing on its methodologies, parameters, and considerations for achieving reliable outcomes.

Understanding Trial Production

Trial production, often referred to as pilot production or pre-production, is the process of manufacturing a small batch of products under conditions that closely mimic full-scale production. The primary goal is to test the production process, equipment, and materials to ensure they meet design specifications and quality standards. This phase allows manufacturers to refine processes, optimize workflows, and confirm product performance without the high costs and risks associated with large-scale production.

The scope of trial production varies depending on the industry, product complexity, and production goals. For example, in electronics, trial production may focus on circuit board assembly and functionality testing, while in automotive manufacturing, it may involve assembling a prototype vehicle to evaluate structural integrity and performance.

Key Objectives of Trial Production

Trial production serves several technical purposes, each aimed at ensuring a smooth transition to mass production. These objectives include:

- Process Validation: Confirming that manufacturing processes produce consistent, high-quality products.

- Equipment Testing: Verifying that machinery and tools perform reliably under production conditions.

- Material Assessment: Ensuring raw materials meet specifications and perform as expected during production.

- Quality Assurance: Identifying defects or inconsistencies in the product or process before scaling up.

- Cost Estimation: Evaluating production costs to optimize resource allocation and budgeting.

Stages of Trial Production

Trial production follows a structured process to achieve its objectives systematically. The stages outlined below provide a clear framework for implementation.

Planning and Preparation

The planning phase involves defining the scope, objectives, and technical requirements of the trial. Engineers and production managers collaborate to establish production parameters, select materials, and configure equipment. Key activities include:

- Developing a detailed production plan with timelines and milestones.

- Specifying material requirements, including tolerances and quality standards.

- Setting up equipment and calibrating tools to match design specifications.

A critical aspect of planning is defining measurable parameters to evaluate success. These parameters may include dimensional accuracy, cycle time, defect rate, and material waste.

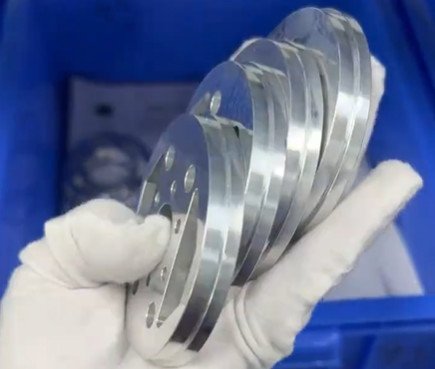

Prototype Manufacturing

In this stage, a small batch of products is manufactured using the planned processes and equipment. The focus is on replicating the conditions of full-scale production as closely as possible. Key considerations include:

- Tooling Setup: Ensuring molds, dies, or fixtures are correctly installed and aligned.

- Process Parameters: Monitoring variables such as temperature, pressure, and speed to maintain consistency.

- Operator Training: Training staff to operate equipment and follow standard operating procedures (SOPs).

The table below outlines typical process parameters for trial production in injection molding, a common manufacturing method:

| Parameter | Description | Typical Range |

|---|---|---|

| Injection Pressure | Pressure applied to inject molten material into the mold | 50–150 MPa |

| Mold Temperature | Temperature of the mold surface | 20–80°C |

| Cycle Time | Total time to complete one molding cycle | 10–60 seconds |

| Material Feed Rate | Rate at which material is fed into the machine | 50–200 g/s |

Testing and Evaluation

Once the trial batch is produced, products undergo rigorous testing to assess quality and performance. Testing methods depend on the product type and industry standards. Common tests include:

- Dimensional Inspection: Measuring product dimensions against design specifications using tools like calipers or coordinate measuring machines (CMM).

- Functional Testing: Verifying that the product performs its intended function, such as electrical conductivity in circuits or load-bearing capacity in mechanical parts.

- Material Testing: Analyzing material properties, such as tensile strength or chemical composition, to ensure compliance with standards.

Data collected during testing is compared against predefined acceptance criteria. Any deviations are documented for further analysis.

Process Optimization

Based on test results, engineers refine the production process to address any issues. Optimization may involve adjusting process parameters, modifying tooling, or revising material specifications. For example, if dimensional inaccuracies are detected, the mold design may be adjusted, or injection pressure may be recalibrated.

Optimization is iterative, often requiring multiple trial runs to achieve the desired results. Each iteration is documented to track changes and their impact on product quality.

Documentation and Reporting

Comprehensive documentation is essential for transitioning to full-scale production. Reports typically include:

- Process parameters and settings used during the trial.

- Test results and quality metrics.

- Recommendations for process improvements.

- Lessons learned and potential risks for mass production.

These documents serve as a reference for production teams and ensure consistency when scaling up.

Technical Considerations in Trial Production

Several technical factors influence the success of trial production. These considerations require careful attention to ensure reliability and efficiency.

Equipment Calibration and Maintenance

Accurate equipment calibration is critical to achieving consistent results. For example, in CNC machining, spindle speed and feed rate must be precisely controlled to meet tolerances. Regular maintenance schedules should be established to prevent equipment failures during the trial.

Material Selection and Consistency

The choice of materials significantly impacts product quality. During trial production, materials must match the specifications intended for mass production. Variations in material properties, such as batch-to-batch inconsistencies, can lead to defects. For instance, in metal casting, variations in alloy composition can affect mechanical properties, requiring strict quality control.

Process Control and Monitoring

Real-time monitoring of process parameters ensures consistency during trial production. Sensors and data acquisition systems can track variables like temperature, pressure, and humidity. Statistical process control (SPC) techniques, such as control charts, help identify trends and deviations, enabling proactive adjustments.

Scalability Assessment

Trial production must evaluate whether processes can be scaled efficiently. This includes assessing equipment capacity, production cycle times, and labor requirements. For example, a process that works well for a batch of 100 units may encounter bottlenecks when scaled to 10,000 units, necessitating redesign.

Common Issues in Trial Production

While pain points are not always present, certain issues can arise during trial production, requiring systematic resolution. The table below summarizes common issues and their solutions:

| Issue | Description | Solution |

|---|---|---|

| Dimensional Inaccuracies | Products do not meet specified dimensions | Adjust tooling or recalibrate equipment |

| Material Defects | Inconsistencies in material properties | Implement stricter supplier quality checks |

| Equipment Downtime | Machine failures during production | Schedule preventive maintenance |

| High Defect Rate | Excessive defective products in the batch | Optimize process parameters and retrain operators |

Best Practices for Effective Trial Production

To maximize the success of trial production, manufacturers should adopt the following best practices:

- Collaborate Across Teams: Involve design, engineering, and quality control teams to ensure alignment on objectives and specifications.

- Use Standardized Procedures: Implement SOPs to maintain consistency and reduce human error.

- Leverage Data Analytics: Use data from trial runs to identify patterns and optimize processes.

- Prioritize Quality Control: Conduct thorough inspections at each stage to catch issues early.

- Plan for Iterations: Anticipate multiple trial runs to refine processes and achieve desired outcomes.

Conclusion

Trial production is a vital step in ensuring the success of manufacturing processes. By following a systematic approach—encompassing planning, prototype manufacturing, testing, optimization, and documentation—manufacturers can validate processes, ensure product quality, and minimize risks before full-scale production. Technical considerations, such as equipment calibration, material consistency, and process monitoring, play a crucial role in achieving reliable results. By addressing potential issues and adhering to best practices, trial production sets the foundation for efficient, high-quality manufacturing.