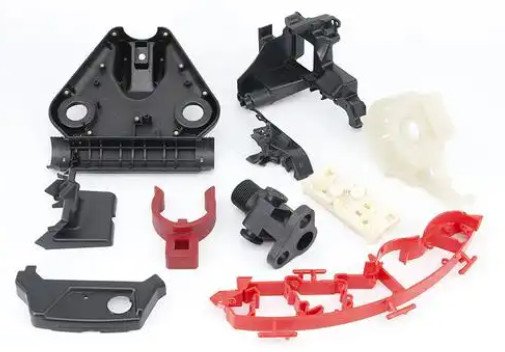

Plastic prototypes are essential in product development, enabling designers and engineers to test functionality, validate designs, and refine concepts before mass production. This article explores the manufacturing processes, materials, design considerations, and applications of plastic prototypes, providing a detailed, technical overview for professionals in engineering and product development.

Manufacturing Processes for Plastic Prototypes

Several manufacturing processes are used to create plastic prototypes, each suited to specific requirements such as speed, precision, or production volume. Below are the primary methods employed.

3D Printing

3D printing, or additive manufacturing, is a widely used method for creating plastic prototypes due to its speed and flexibility. Technologies like Fused Deposition Modeling (FDM) and Stereolithography (SLA) are common.

- FDM: Extrudes molten thermoplastic filament (e.g., ABS, PLA) layer by layer. Layer thickness ranges from 0.1 to 0.3 mm, with build volumes up to 300 x 300 x 600 mm for desktop printers. Suitable for functional and concept prototypes.

- SLA: Uses a UV laser to cure liquid resin (e.g., photopolymer) into solid parts. Resolution is 0.025–0.1 mm, ideal for high-detail form prototypes with smooth surfaces.

- Applications: Rapid iteration of designs, small-batch testing, and complex geometries unachievable by subtractive methods.

CNC Machining

Computer Numerical Control (CNC) machining involves cutting plastic blocks or sheets using tools like mills and lathes. It offers high precision, with tolerances as tight as ±0.01 mm, and is suitable for prototypes requiring exact dimensions or specific material properties.

- Process: Material is removed from a solid block using multi-axis machines (3-axis or 5-axis). Common plastics include ABS, PC, and POM.

- Applications: Functional prototypes for mechanical testing, such as gears or housings, and low-volume production runs.

Injection Molding Prototypes

Injection molding prototypes use simplified molds to produce parts that closely resemble final production components. Molds are typically made from aluminum for cost efficiency, with cycle times ranging from 20 to 60 seconds per part.

- Process: Molten plastic (e.g., ABS, PC) is injected into a mold cavity under high pressure (500–1500 bar). Parts can have wall thicknesses of 1–3 mm.

- Applications: Testing fit, finish, and mechanical properties in pre-production stages.

Vacuum Casting

Vacuum casting involves creating a silicone mold from a master model (often 3D-printed) and casting polyurethane resins to replicate plastic parts. It produces 10–50 parts per mold with tolerances of ±0.2 mm.

- Process: Liquid resin is poured into a silicone mold under vacuum to eliminate air bubbles. Curing takes 1–24 hours, depending on the resin.

- Applications: Small-batch production for form and functional prototypes, especially for consumer electronics.

Plastic Materials for Prototyping

Material selection is critical for plastic prototypes, as it affects functionality, appearance, and manufacturability. The table below summarizes common plastics and their properties.

| Material | Properties | Applications | Common Processes |

|---|---|---|---|

| ABS | Tensile strength: 40–50 MPa; impact-resistant; easy to machine | Structural components, housings | FDM, CNC, injection molding |

| PLA | Tensile strength: 50–70 MPa; biodegradable; brittle | Concept models, visual prototypes | FDM |

| PC | Tensile strength: 60–70 MPa; transparent; high impact resistance | Lenses, medical device components | CNC, injection molding |

| POM | Tensile strength: 60–90 MPa; low friction; wear-resistant | Gears, bearings | CNC, injection molding |

| PETG | Tensile strength: 50–60 MPa; flexible; chemical-resistant | Functional and form prototypes | FDM, vacuum casting |

Prototype Types and Testing

Plastic prototypes serve different purposes depending on the development stage. Each type is designed to validate specific aspects of a product.

Concept Prototypes

Concept prototypes focus on visualizing design ideas. They are typically low-fidelity, made using 3D printing (e.g., PLA or resin) to assess aesthetics and ergonomics.

- Purpose: Communicate design intent to stakeholders.

- Testing: Visual inspection, user feedback on shape and size.

Form Prototypes

Form prototypes emphasize aesthetics and surface finish. Materials like ABS or PC are used to mimic the final product’s appearance, with post-processing (e.g., sanding, painting) to achieve smooth surfaces.

- Purpose: Evaluate design aesthetics and ergonomics.

- Testing: Surface quality assessment, color matching.

Functional Prototypes

Functional prototypes replicate the mechanical or operational aspects of the final product. Materials like POM or PC are chosen for durability and performance.

- Purpose: Test mechanical properties, fit, and function.

- Testing: Includes tensile testing (e.g., ASTM D638), thermal resistance (up to 80–120°C for ABS), and assembly validation.

Prototype Testing Methods

Testing ensures prototypes meet design specifications. Common tests include:

- Mechanical Testing: Measures tensile strength, impact resistance, and fatigue using standards like ASTM or ISO.

- Thermal Testing: Evaluates performance under temperature ranges (e.g., -20°C to 80°C for PC).

- Fit and Assembly: Verifies tolerances and compatibility with other components.

Design and Tools for Plastic Prototypes

Effective prototype development requires precise design tools and methodologies to translate concepts into physical parts.

CAD Modeling

Computer-Aided Design (CAD) software, such as SolidWorks or Fusion 360, is used to create detailed 3D models. Models include specifications for dimensions, tolerances (e.g., ±0.1 mm), and material properties.

- Process: Designers create parametric models, enabling iterative adjustments.

- Output: STL or STEP files for 3D printing or CNC machining.

Reverse Engineering

Reverse engineering involves scanning existing objects (using 3D scanners with 0.05–0.1 mm accuracy) to create digital models for prototyping.

- Process: Point cloud data is converted into CAD models, then used for prototype fabrication.

- Applications: Recreating legacy parts or modifying existing designs.

Applications of Plastic Prototypes

Plastic prototypes are integral to various industries, enabling rapid development and validation of products.

Product Development

Prototypes bridge the gap between concept and production, allowing iterative testing of designs. They reduce development time by identifying issues early, with 3D printing enabling iterations within 24–48 hours.

Automotive Industry

Plastic prototypes are used for components like dashboards, brackets, and interior panels. Materials like ABS and PC are tested for impact resistance and thermal stability (e.g., 80–100°C for under-hood parts).

Medical Devices

Prototypes for medical devices, such as surgical tools or enclosures, require biocompatible materials (e.g., specific PC grades). Tolerances are tight (e.g., ±0.05 mm) to ensure fit with other components.

Consumer Electronics

Plastic prototypes for phone cases, wearables, or accessories use ABS or PETG for durability and aesthetics. Vacuum casting is common for small batches to test market response.

Considerations in Plastic Prototype Development

While plastic prototypes are versatile, certain limitations must be addressed to ensure success.

| Consideration | Description | Impact |

|---|---|---|

| Material Selection | Choosing the right plastic for strength, aesthetics, or thermal properties. | Affects prototype performance and testing accuracy. |

| Process Limitations | 3D printing may have layer lines; CNC machining is costlier for complex shapes. | Influences cost, lead time, and surface quality. |

| Tolerance Requirements | Prototypes must meet precise tolerances (e.g., ±0.1 mm for CNC). | Ensures compatibility with final production parts. |

Conclusion

Plastic prototypes are a cornerstone of modern product development, offering flexibility, cost-efficiency, and rapid iteration. By leveraging processes like 3D printing, CNC machining, injection molding, and vacuum casting, engineers can create prototypes tailored to specific needs. Material selection, design tools, and testing protocols further enhance their utility across industries like automotive, medical, and consumer electronics. Understanding the technical aspects of these processes and materials ensures effective prototype development, paving the way for successful product launches.