3-axis CNC (Computer Numerical Control) machines are fundamental tools in modern manufacturing, offering precise control over three linear axes—X, Y, and Z—for cutting, drilling, and milling operations. These machines are widely adopted due to their simplicity, cost-effectiveness, and versatility in producing parts with moderate complexity. This article provides a comprehensive overview of their features, technical specifications, applications, and limitations, supplemented by a comparison with multi-axis machines to highlight their role in various industries.

Core Features of 3-Axis CNC Machines

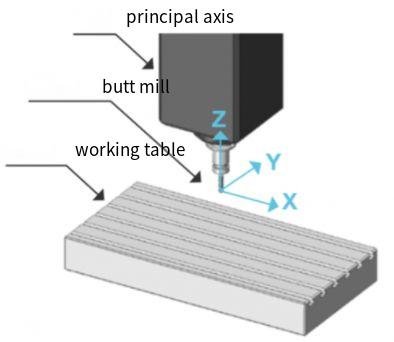

3-axis CNC machines are defined by their ability to move a cutting tool or workpiece along three perpendicular axes, enabling precise material removal. Below, we detail their key features and technical specifications.

Axis Configuration and Motion

The 3-axis CNC machine operates along three linear axes:

- X-Axis: Horizontal movement from left to right, typically along the length of the workpiece.

- Y-Axis: Horizontal movement from front to back, controlling the width of the workpiece.

- Z-Axis: Vertical movement, adjusting the depth of cut or tool height.

These axes are driven by high-precision motors (stepper or servo) with positioning accuracy ranging from ±0.01 mm to ±0.05 mm and repeatability of ±0.005 mm to ±0.02 mm, depending on the machine’s quality and configuration. The motion is controlled by a CNC controller interpreting G-code, ensuring accurate tool paths for milling, drilling, or boring operations.

Key Components and Specifications

A 3-axis CNC machine comprises several critical components, each contributing to its precision and functionality. The table below summarizes these components and their typical specifications:

| Component | Function | Typical Specifications |

|---|---|---|

| Spindle | Rotates the cutting tool for material removal. | Speed: 1,000–24,000 RPM; Power: 1–10 kW |

| Linear Guides | Ensure smooth and precise axis movement. | Accuracy: ±0.01–0.05 mm; Material: Hardened steel |

| Stepper/Servo Motors | Drive axis motion with high torque and precision. | Torque: 1–5 Nm; Resolution: 0.001 mm/step |

| Controller | Processes G-code to coordinate machine operations. | Processor: 1–2 GHz; Memory: 4–16 GB |

| Worktable | Secures the workpiece using T-slots or vises. | Size: 300x300 mm to 2000x1000 mm |

Control Systems and Programming

The control system interprets G-code and M-code, generated by CAD/CAM software such as Mastercam, Fusion 360, or UG (NX). These programs translate 3D models into tool paths, specifying parameters like feed rate (20–500 mm/min), spindle speed (1,000–24,000 RPM), and depth of cut (0.1–5 mm per pass). The programming process is straightforward, making 3-axis CNC machines accessible to operators with basic training. Common controllers include FANUC, Siemens, or open-source systems like Mach3, offering user-friendly interfaces for real-time adjustments.

Material and Tool Compatibility

3-axis CNC machines are compatible with a wide range of materials and tools:

- Materials: Metals (aluminum, steel, copper, titanium), plastics (PVC, ABS, acrylic), wood (hardwood, softwood), and composites (carbon fiber, fiberglass).

- Tools: End mills (2–10 mm diameter), drills, taps, and reamers, selected based on material hardness and machining requirements.

For example, milling aluminum might use a 6 mm carbide end mill at 12,000 RPM and 150 mm/min feed rate, while wood cutting might employ a 10 mm tool at 18,000 RPM and 300 mm/min.

Cost and Efficiency

3-axis CNC machines are cost-effective, with purchase prices typically ranging from $5,000 to $50,000, approximately 50%–70% less than 4-axis or 5-axis machines. Their simple design reduces maintenance costs, and their efficiency in handling planar or simple curved surfaces makes them ideal for small to medium-batch production. Cycle times for basic operations, such as drilling a 10 mm hole in aluminum, can be as low as 10–20 seconds per feature.

Applications of 3-Axis CNC Machines

3-axis CNC machines are employed across diverse industries due to their reliability and versatility. Below are their primary applications, with specific examples.

Mechanical Manufacturing

In general manufacturing, 3-axis CNC machines produce simple components and molds, including:

- Flanges and Gear Blanks: Milling flat surfaces or keyways with tolerances of ±0.02 mm.

- Molds: Rough machining of plastic or stamping molds, achieving surface finishes of Ra 1.6–3.2 µm.

- Shafts: End-face milling and keyslot cutting for mechanical assemblies.

For instance, a 3-axis machine might mill a 200 mm diameter steel flange with a 5 mm keyway in a single setup.

Automotive Industry

The automotive sector uses 3-axis CNC machines for:

- Engine Components: Drilling bolt holes in engine brackets or milling transmission housings with ±0.01 mm accuracy.

- Interior Parts: Contouring plastic dashboards or panels using a 3 mm ball-end mill.

- Brake Rotors: Machining flat surfaces to ensure uniform thickness (e.g., 20 mm ±0.05 mm).

A typical setup might involve a 1000x600 mm table and a 5 kW spindle processing steel at 100 mm/min.

Electronics and Medical Devices

In electronics and medical manufacturing, 3-axis CNC machines are used for:

- Electronics Housings: Milling aluminum phone shells or PC chassis with precise cutouts for ports.

- Medical Components: Drilling holes in surgical tool handles or milling titanium bone plates with ±0.005 mm tolerances.

- Prototyping: Creating plastic enclosures for diagnostic devices.

For example, a 3-axis machine might drill 2 mm holes in a stainless steel surgical instrument with a cycle time of 15 seconds per hole.

Woodworking and Furniture

In woodworking, 3-axis CNC machines excel at:

- Panel Cutting: Shaping wooden boards for furniture with intricate patterns.

- Joinery: Milling mortise-and-tenon joints for cabinets or window frames.

- Engraving: Carving decorative designs on hardwood surfaces.

A typical operation might use a 12 mm router bit at 20,000 RPM to cut oak panels at 400 mm/min.

Education and Research

3-axis CNC machines are widely used in academic settings for:

- Teaching: Demonstrating CNC principles to students in engineering programs.

- Prototyping: Fabricating small-batch prototype parts to validate designs.

- Research: Machining experimental components for mechanical or material studies.

Small desktop models (e.g., 300x300 mm work envelope) are popular in labs due to their affordability and ease of use.

Comparison with Multi-Axis CNC Machines

To understand the role of 3-axis CNC machines, it’s useful to compare them with 4-axis and 5-axis machines. The table below highlights key differences:

| Dimension | 3-Axis CNC Machine | 4/5-Axis CNC Machine |

|---|---|---|

| Processing Complexity | Flat surfaces, simple curves | Complex surfaces, undercuts, multi-angle features |

| Cost | Low ($5,000–$50,000) | High ($50,000–$200,000+) |

| Programming Difficulty | Simple (basic G-code) | Complex (advanced CAM required) |

| Applications | Small to medium batches, simple parts | Large batches, high-precision complex parts |

Limitations of 3-Axis CNC Machines

While highly effective for many tasks, 3-axis CNC machines have limitations that may require complementary equipment:

- Geometric Constraints: Inability to machine undercuts, deep cavities, or multi-angle features without multiple setups.

- Tool Orientation: Fixed tool direction (typically vertical) limits access to angled surfaces, requiring manual repositioning.

- Setup Time: Complex parts may need multiple clamping adjustments, increasing setup time and error risk.

For complex geometries, 3-axis machines are often used for roughing, followed by 4-axis or 5-axis machines for finishing, balancing cost and precision.

Best Practices for Optimal Performance

To ensure efficiency and precision, operators should follow these practices:

- Tool Selection: Match tool type and size (e.g., 3 mm for finishing, 8 mm for roughing) to material and task.

- Maintenance: Regularly lubricate linear guides and check motor alignment to maintain ±0.01 mm accuracy.

- Programming Optimization: Use CAM software to minimize tool travel and reduce cycle times by up to 20%.

- Workpiece Fixturing: Ensure secure clamping to prevent vibration, which can affect surface finish (e.g., Ra 1.6 µm).

Conclusion

3-axis CNC machines are indispensable in modern manufacturing, offering a cost-effective and efficient solution for producing simple to moderately complex parts. Their three-axis configuration, robust components, and compatibility with diverse materials make them suitable for industries such as mechanical manufacturing, automotive, electronics, woodworking, and education. While limited in handling complex geometries, their simplicity, low cost, and ease of operation make them a cornerstone of small to medium-scale production. By combining 3-axis machines with multi-axis systems for specific tasks, manufacturers can achieve an optimal balance of cost, precision, and efficiency.