5-axis CNC machines represent a pinnacle in precision manufacturing, offering unparalleled capabilities for machining complex geometries. By incorporating three linear axes (X, Y, Z) and two rotational axes (commonly A+B, A+C, or B+C), these machines enable multi-directional tool or workpiece movement, making them ideal for intricate parts. This article systematically explores their features, technical specifications, limitations, and applications across various industries, providing a comprehensive overview for professionals seeking technical insights.

Core Features of 5-Axis CNC Machines

The advanced capabilities of 5-axis CNC machines stem from their unique design and functionality. Below, we detail their core features, supported by technical parameters to highlight their precision and versatility.

Axis Configuration and Simultaneous Motion

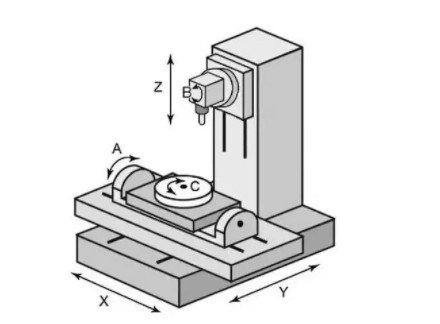

5-axis CNC machines combine three linear axes (X for left-right, Y for front-back, Z for up-down) with two rotational axes, typically A (rotation around X-axis), B (rotation around Y-axis), or C (rotation around Z-axis). Common configurations include A+C for horizontal machines with rotating workpieces and B+C for vertical machines with rotating tools. The hallmark of these machines is their ability to perform 5-axis simultaneous motion, allowing the tool to maintain an optimal angle relative to the workpiece surface, enhancing surface quality and efficiency.

Technical Parameters:

- X-axis travel: 500–2,000 mm

- Y-axis travel: 400–1,500 mm

- Z-axis travel: 300–1,000 mm

- A-axis rotation: ±110° to ±120°

- B/C-axis rotation: ±360° (continuous)

- Positioning accuracy: ±0.001–±0.005 mm

- Repeatability: ±0.0005–±0.002 mm

This multi-axis capability enables machining of complex surfaces, undercuts, and multi-sided parts in a single setup, reducing cumulative errors from repositioning.

Enhanced Machining Capabilities

5-axis CNC machines excel in producing complex spatial surfaces (e.g., turbine blades, impellers), undercut features (e.g., deep-cavity molds), and polyhedral parts. Unlike 3-axis or 4-axis machines, they can machine all surfaces of a part without multiple setups, reducing alignment errors by up to 80%. This capability is critical for industries requiring high precision, such as aerospace and medical manufacturing.

Key Advantages:

- Single-setup machining for multi-sided parts

- Ability to machine deep cavities and undercuts

- High surface finish quality (Ra 0.2–0.8 µm)

Advanced Programming and Control Systems

Programming 5-axis machines requires sophisticated CAD/CAM software (e.g., UG NX, Mastercam, HyperMill) to generate tool paths accounting for rotational axis limits, tool length compensation, and workpiece coordinate transformations. The Rotation Tool Center Point (RTCP) function ensures the tool center remains aligned with the programmed position, compensating for rotational movements. These systems demand skilled operators familiar with collision avoidance and dynamic accuracy calibration.

Technical Parameters:

- Control resolution: 0.0001 mm

- Feed rate: Up to 3,000 mm/min

- Interpolation cycle time: 1–2 ms

Cost and Efficiency Considerations

5-axis CNC machines are significantly more expensive than their 3-axis or 4-axis counterparts, with entry-level models costing approximately $70,000–$100,000 and high-end precision machines reaching $500,000 or more. However, for complex parts, they can reduce machining time by 50%–100% (e.g., impeller machining time reduced by 60% compared to 3-axis systems). For simpler parts, the efficiency gain over 3/4-axis machines is minimal.

Limitations and Maintenance Requirements

While 5-axis CNC machines offer significant advantages, they come with specific limitations:

- High Maintenance Costs: Precision components like rotary axis bearings and servo motors require regular calibration (e.g., laser interferometry every 6 months), with annual maintenance costs of 5%–10% of the machine’s price.

- Blank Precision Requirements: Excessive blank shape errors can cause uneven tool loading, affecting machining quality and requiring precise pre-machining.

- Operator Skill: The complexity of 5-axis programming and operation demands highly trained personnel, increasing labor costs.

Applications of 5-Axis CNC Machines

5-axis CNC machines are indispensable in industries requiring high-precision, complex components. Below are their primary applications, with examples illustrating their practical use.

Aerospace Industry

Aerospace manufacturing relies on 5-axis CNC machines for components with intricate geometries and tight tolerances. Examples include:

- Turbine Blades: Complex airfoil surfaces and thin-walled structures, machined from titanium alloys with tolerances of ±0.01 mm.

- Airframe Components: Large structural panels and wing connectors with multi-angle holes and curved surfaces, often machined on 5-axis gantry machines.

Example: A turbine blade with a 150 mm length and complex curvature can be machined in a single setup, achieving a surface finish of Ra 0.4 µm.

Mold Manufacturing

Mold making benefits from 5-axis machines’ ability to produce complex cavities and undercut features. Applications include:

- Automotive Molds: Deep-cavity molds for car body panels with intricate undercuts.

- Precision Casting Molds: Molds for aerospace turbine blades, requiring exact surface matching.

Example: A mold for an automotive dashboard with a 500 mm x 300 mm cavity and undercut features can be machined in one setup, reducing lead time by 50%.

Medical Industry

The medical sector uses 5-axis CNC machines for biocompatible components with complex geometries. Examples include:

- Orthopedic Implants: Hip joint components (e.g., femoral heads) with spherical and irregular surfaces, machined from titanium.

- Surgical Robot Parts: Articulated joints requiring high-precision mating surfaces.

Example: A titanium hip implant with a 50 mm diameter spherical head and curved stem, machined with tolerances of ±0.005 mm.

Energy and Power Equipment

The energy sector employs 5-axis machines for durable, complex components. Applications include:

- Wind Power Gearboxes: Planetary gear systems with complex tooth profiles and transitions.

- Nuclear Components: Heat exchanger tube sheets with multi-angle holes and curved surfaces.

Example: A stainless steel impeller with a 200 mm diameter, machined at 18,000 RPM with a feed rate of 2,500 mm/min.

Luxury and Craftsmanship

5-axis CNC machines are used for high-end products requiring intricate designs, such as:

- Metal Artwork: Sculptures with complex, multi-directional textures.

- Luxury Watch Components: Micro-sized gears and cams with intricate profiles.

Comparison with 3-Axis and 4-Axis CNC Machines

The following table compares 5-axis CNC machines with 3-axis and 4-axis systems, highlighting their differences in capability and application:

| Aspect | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

|---|---|---|---|

| Rotational Axes | 0 | 1 | 2 |

| Machining Scope | Flat/simple 3D features | Inclined surfaces/radial features | Complex surfaces/undercuts |

| Setup Frequency | Multiple (multi-sided parts) | 1–2 | 1 (full access) |

| Accuracy | ±0.01–±0.05 mm | ±0.005–±0.01 mm | ±0.001–±0.005 mm |

| Typical Parts | Flanges, flat plates | Camshafts, mold sliders | Turbine blades, impellers |

Conclusion

5-axis CNC machines are the ultimate solution for manufacturing high-precision, complex parts, offering unmatched flexibility and accuracy. Their ability to machine intricate geometries in a single setup makes them indispensable in industries such as aerospace, mold making, medical, energy, and luxury goods. Despite their high cost and maintenance requirements, the efficiency and precision gains for complex parts justify their investment. For simpler components, 3-axis or 4-axis machines may suffice, but for applications demanding complex surfaces and stringent tolerances, 5-axis CNC machines are the definitive choice.