Titanium pins, made from titanium or its alloys, are essential standard components valued for their high strength, low density, and exceptional corrosion resistance. Widely used in industries such as aerospace, medical, automotive, and manufacturing, these pins ensure reliable connections, precise positioning, and durability in demanding environments. This article provides a comprehensive, technical overview of titanium pins, including their material properties, classifications, manufacturing processes, applications, and design considerations.

Material Properties of Titanium Pins

Titanium pins owe their versatility to the unique properties of titanium and its alloys, such as TC4 (Ti-6Al-4V). These properties make them suitable for applications requiring strength, lightweight design, and resistance to harsh conditions.

| Property | Value | Description |

|---|---|---|

| Density | 4.5 g/cm³ | Approximately 60% of steel, reducing weight in aerospace and automotive applications. |

| Tensile Strength | 900-1600 MPa | High strength, especially in TC4 alloy, for load-bearing connections. |

| Corrosion Resistance | Excellent | Resists dilute sulfuric acid, hydrochloric acid, chlorine, and organic acids. |

| Biocompatibility | High | Non-toxic, ideal for medical implants like artificial joints. |

| Magnetic Property | Non-magnetic | Suitable for MRI equipment and sensitive electronics. |

These properties enable titanium pins to perform reliably in extreme conditions, from corrosive marine environments to biocompatible medical applications.

Types and Applications of Titanium Pins

Titanium pins are categorized based on their design and function. Each type serves specific purposes in various industries, ensuring secure fastening, precise positioning, or structural integrity.

Titanium Spring Pins

Spring pins, also known as roll pins, are tubular with a longitudinal slot, allowing elastic compression during insertion.

- Structure: Cylindrical with a slot, slightly larger than the installation hole.

- Working Principle: When inserted, the pin compresses and expands, creating friction and spring force for secure fastening.

- Applications: Used in mechanical connections, automotive engine components, and aerospace assemblies.

- Example: Securing gears in automotive transmissions or fastening aircraft control linkages.

Titanium Clevis Pins

Clevis pins feature a head and a shank with a hole or slot for securing with a cotter pin or clip.

- Structure: Typically U- or T-shaped with a head and a perforated shank.

- Working Principle: Inserted through aligned holes in components, secured by bending or spreading the tail to prevent dislodgement.

- Applications: Common in construction (e.g., steel beam connections), mechanical joints, and aerospace linkages.

- Example: Connecting hydraulic cylinder arms in heavy machinery.

Titanium Dowel Pins

Dowel pins are solid, cylindrical pins designed for precise alignment and positioning.

- Structure: Smooth, cylindrical with high dimensional accuracy (±0.005 mm).

- Working Principle: Ensures precise alignment of components, maintaining assembly accuracy and interchangeability.

- Applications: Used in mold manufacturing, automotive engine assembly, and electronics.

- Example: Aligning cylinder heads with engine blocks in automotive manufacturing.

Manufacturing Processes for Titanium Pins

Producing titanium pins requires advanced manufacturing techniques to achieve precise dimensions and optimal material properties.

Forging

Hot forging at 900-1000°C shapes titanium into pins, improving grain structure and strength. This process minimizes defects and enhances durability.

CNC Machining

CNC machining ensures tight tolerances (±0.01 mm) for precision applications. Titanium’s low thermal conductivity requires carbide tools and advanced cooling to prevent overheating.

Heat Treatment

Heat treatment, such as solution treating at 800-850°C and aging at 500-600°C, optimizes strength and fatigue resistance, particularly for TC4 alloy pins.

Surface Treatment

Anodizing or polishing enhances corrosion resistance and surface smoothness. Anodizing forms a protective oxide layer, while polishing achieves Ra 0.4–1.6 µm for medical or aesthetic purposes.

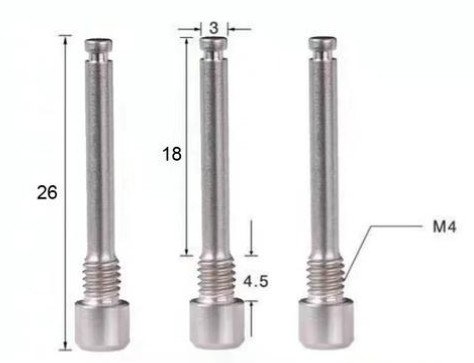

Technical Specifications and Standards

Titanium pins are manufactured to meet industry standards, ensuring quality and performance. Common grades and standards include:

| Grade | Composition | Applications | Standard |

|---|---|---|---|

| Grade 2 | Commercially pure titanium | Marine hardware, chemical processing | ASTM B348, ISO 5832-2 |

| Grade 5 (TC4) | Ti-6Al-4V | Aerospace, automotive, medical implants | ASTM B348, ISO 5832-3 |

| Grade 23 | Ti-6Al-4V ELI | Medical implants, dental pins | ASTM F136, ISO 5832-3 |

Specifications:

- Diameter: 0.5–10 mm

- Length: 5–100 mm (customizable)

- Tolerance: ±0.005–0.01 mm

- Threading: Optional (e.g., M2–M10)

- Surface Roughness: Ra 0.4–1.6 µm

Quality Control and Testing

Quality assurance ensures titanium pins meet performance and safety standards.

Tensile Testing

Tests confirm tensile strength (e.g., 900 MPa minimum for TC4) and ductility per ASTM standards.

Corrosion Testing

Salt spray tests (ASTM B117) verify resistance, with pins enduring over 1000 hours in corrosive environments.

Dimensional Inspection

Coordinate Measuring Machines (CMM) ensure dimensional accuracy within specified tolerances.

Non-Destructive Testing

Ultrasonic and X-ray inspections detect internal flaws, critical for aerospace and medical applications.

Limitations and Considerations

Despite their advantages, titanium pins have limitations that require consideration:

- Cost: Higher material and processing costs compared to steel or aluminum.

- Machinability: Titanium’s hardness and low thermal conductivity increase machining difficulty.

- Galling: Threaded pins may gall, requiring coatings or lubricants.

- Availability: Specialized grades like Grade 23 may have longer lead times.

Conclusion

Titanium pins are vital components in industries requiring high strength, corrosion resistance, and biocompatibility. Their diverse types—spring pins, clevis pins, and dowel pins—cater to specific needs in aerospace, automotive, medical, and industrial applications. By understanding their properties, manufacturing processes, and limitations, professionals can select the appropriate titanium pin for optimal performance and reliability.