Copper electrodes are essential components in numerous industrial and scientific applications due to their superior electrical and thermal conductivity, durability, and versatility. This article provides a detailed examination of copper electrodes, focusing on their physical and chemical properties, classifications, and key applications in electrical discharge machining (EDM), resistance welding, electrochemical processes, electronics, and scientific experiments. Technical specifications and parameters are included to ensure a comprehensive understanding, presented in a structured and professional manner.

Physical Properties of Copper Electrodes

Copper electrodes are prized for their exceptional physical properties, which enable their use in high-performance applications. The key physical characteristics include:

- Electrical Conductivity: Copper exhibits an electrical conductivity of over 98% IACS (International Annealed Copper Standard), making it one of the most conductive electrode materials. This ensures efficient current transfer in applications like EDM and welding.

- Density: Copper has a density of 8.96 g/cm³, providing a balance of strength and weight suitable for precise machining and handling.

- Thermal Conductivity: With a thermal conductivity of 401 W·m⁻¹·K⁻¹, copper efficiently dissipates heat, critical for high-temperature processes such as resistance welding and EDM.

- Thermal Expansion Coefficient: At 25°C, copper’s thermal expansion coefficient is 16.5 µm·m⁻¹·K⁻¹, indicating moderate expansion under temperature changes, which helps maintain dimensional stability in thermal-intensive applications.

- Melting Point: Copper’s melting point is 1,085°C, allowing it to withstand high temperatures without significant deformation.

- Mechanical Strength: In its annealed state, copper has a tensile strength of 210–250 MPa, sufficient for applications requiring moderate mechanical durability.

These properties make copper electrodes ideal for applications demanding high conductivity, thermal management, and structural integrity.

Chemical Properties of Copper Electrodes

Copper electrodes demonstrate notable chemical stability, which enhances their suitability for various environments:

- Stability at Room Temperature: Copper is relatively stable under standard conditions, resisting rapid degradation in non-aggressive environments.

- Oxidation Behavior: In the presence of oxygen, copper reacts to form copper oxide (Cu₂O or CuO), creating a protective oxide layer that prevents further oxidation. This layer enhances durability in applications like electroplating but may require surface treatment in precision processes to maintain conductivity.

- Corrosion Resistance: Copper exhibits good resistance to corrosion in neutral or mildly acidic environments. However, in highly acidic or alkaline conditions, protective coatings or alloying may be necessary to prevent degradation.

These chemical properties ensure copper electrodes perform reliably in electrochemical and other chemically active environments.

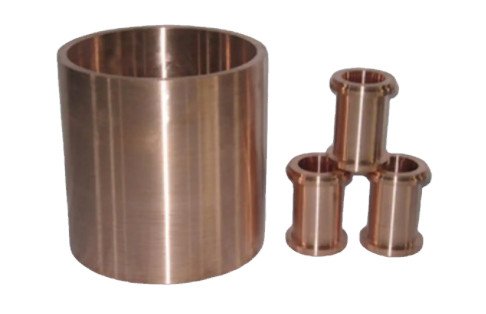

Types of Copper Electrodes

Copper electrodes are classified into several types, each designed for specific applications based on their composition and properties. The main types include:

Pure Copper Electrodes

Pure copper electrodes, typically made from high-purity copper (99.9% Cu, e.g., C11000), are widely used due to their excellent conductivity and stability. Key characteristics include:

- Conductivity: Over 98% IACS, ideal for EDM and electrochemical applications.

- Processing Stability: These electrodes maintain stable machining performance under challenging conditions, with minimal arcing and low material loss (tool wear rate: 0.01–0.1 mm³/min in EDM).

- Precision: Capable of achieving high precision (tolerances ±0.01 mm) and maintaining sharp edges and fine shapes, suitable for mold cavity machining.

- Limitations: Lower mechanical strength (tensile strength: 210–250 MPa) and poor grindability compared to graphite, making machining more challenging.

Copper-Tungsten Alloy Electrodes

Copper-tungsten (CuW) electrodes combine copper’s high thermal conductivity and low loss rate with tungsten’s high melting point (3,422°C) and low thermal expansion. Key features include:

- Composition: Typically 70% tungsten and 30% copper, balancing conductivity (48% IACS) and durability.

- Applications: Widely used for machining mold steel and tungsten carbide workpieces, as well as precision EDM tasks requiring high wear resistance.

- Thermal Properties: Thermal conductivity of approximately 190 W·m⁻¹·K⁻¹ and a low thermal expansion coefficient (6.0–8.0 µm·m⁻¹·K⁻¹).

- Cost: More expensive than pure copper due to tungsten content, limiting their use to high-value applications.

Brass Electrodes

Brass electrodes, an alloy of copper and zinc (typically 60–70% Cu, 30–40% Zn), are less common but still used in specific contexts:

- Conductivity: Lower than pure copper at approximately 28% IACS, resulting in slower machining speeds in EDM.

- Wear and Stability: Higher electrode wear and greater material loss compared to copper, but fewer short circuits during discharge, ensuring stable processing.

- Applications: Rarely used in modern EDM spark machining due to performance limitations but still employed in low-speed wire-cut EDM for cost-sensitive applications.

Technical Specifications of Copper Electrodes

The following table summarizes the key technical specifications of pure copper, copper-tungsten, and brass electrodes:

| Parameter | Pure Copper (C11000) | Copper-Tungsten (70% W, 30% Cu) | Brass (65% Cu, 35% Zn) |

|---|---|---|---|

| Electrical Conductivity (% IACS) | 98–100 | 48 | 28 |

| Thermal Conductivity (W·m⁻¹·K⁻¹) | 401 | 190 | 150 |

| Thermal Expansion (µm·m⁻¹·K⁻¹ at 25°C) | 16.5 | 6.0–8.0 | 20.0 |

| Tensile Strength (MPa) | 210–250 | 600–700 | 300–400 |

| Density (g/cm³) | 8.96 | 14.2 | 8.5 |

| Melting Point (°C) | 1,085 | 3,422 (W), 1,085 (Cu) | 900–940 |

Applications of Copper Electrodes

Copper electrodes are utilized across diverse industries due to their unique properties. Below are their primary applications, with detailed technical insights:

Mold Processing (EDM)

In electrical discharge machining (EDM), copper electrodes are critical for creating precise mold cavities, particularly for complex geometries in industries like aerospace and automotive. Key details include:

- Precision Machining: Pure copper electrodes excel in maintaining sharp edges and intricate shapes, achieving surface roughness values as low as Ra 0.4 µm and tolerances of ±0.01 mm.

- Material Removal Rate (MRR): Typically 0.1–10 mm³/min, depending on parameters like peak current (5–50 A) and pulse duration (1–100 µs).

- Applications: Used in spark EDM for mold cavities in injection molding and die-casting, ensuring high accuracy for critical components.

Resistance Welding

Copper electrodes, particularly pure copper and CuCrZr alloys, are widely used in resistance welding to conduct current, apply pressure, and manage heat. Key applications include:

- Spot Welding: Used in automotive and electronics industries for joining metal sheets, with welding currents ranging from 5,000 to 20,000 A. Pure copper electrodes ensure minimal heat buildup and strong welds.

- Battery Manufacturing: Copper electrodes are used for welding battery tabs and copper foil in lithium-ion and nickel-metal hydride batteries, leveraging their high conductivity (98% IACS) and thermal conductivity (401 W·m⁻¹·K⁻¹).

- Electronic Components: Employed in welding wire harnesses and connectors, where low spatter and consistent welds are critical.

Electrochemical Applications

Copper electrodes play a vital role in electrochemical processes, acting as anodes or cathodes in various systems:

- Secondary Batteries: In lithium-ion and nickel-metal hydride batteries, copper electrodes serve as anodes, absorbing electrons and facilitating reactions with cathode materials. Typical current densities ranges from 1–10 mA/cm².

- Electroplating: Copper electrodes act as anodes in copper sulfate-based baths (0.2–0.6 M CuSO₄, 1.5–2.5 M H₂SO₄), depositing uniform copper layers on substrates for circuit boards and decorative coatings.

- Electrolytic Cells: Used in cells like copper-copper(II) sulfate reference electrodes (standard potential: +0.314 V vs. SHE) and in CO2 reduction systems, achieving faradaic efficiencies up to 85% for CO production.

Electronics Industry

Copper electrodes are integral to electronics manufacturing due to their conductivity and reliability:

- Printed Circuit Boards (PCBs): Copper electrodes are used in electroplating processes to deposit copper traces, with thicknesses ranging from 35–70 µm.

- Wire and Cable Manufacturing: High-purity copper electrodes ensure consistent conductivity in the production of electrical conductors.

Scientific Experiments

High-purity copper electrodes are used in educational and research settings for various experiments:

- Lenz’s Law Demonstrations: Copper electrodes illustrate electromagnetic induction principles in physics experiments.

- Voltaic Cells: Used in constructing simple voltaic cells or fruit batteries, generating potentials of 0.5–1.0 V depending on the electrolyte.

- Electrochemical Reactions: Employed in experiments to demonstrate redox reactions and energy generation through chemical processes.

Manufacturing and Processing of Copper Electrodes

The production of copper electrodes involves precise processes to achieve the desired specifications:

- Material Selection: High-purity copper (99.9% Cu) or alloys like CuCrZr or CuW are chosen based on application needs.

- Forming: Electrodes are shaped via casting, extrusion, or CNC machining, with tolerances as tight as ±0.005 mm for EDM applications.

- Heat Treatment: Annealing (400–600°C) or aging (450–500°C for CuCrZr) enhances mechanical properties without compromising conductivity.

- Surface Finishing: Polishing to achieve surface roughness (Ra < 0.8 µm) or applying coatings to improve corrosion resistance.

Comparison with Other Electrode Materials

The following table compares copper electrodes with graphite, a common alternative in EDM:

| Material | Conductivity (% IACS) | Wear Resistance | Machinability | Cost |

|---|---|---|---|---|

| Pure Copper | 98–100 | Moderate | Moderate | High |

| Graphite | 10–20 | High | High | Low |

Copper offers superior conductivity and precision, while graphite is preferred for cost-sensitive applications with high wear resistance.

Conclusion

Copper electrodes are critical in industries requiring high conductivity, precision, and thermal management. Their physical and chemical properties, diverse types (pure copper, copper-tungsten, brass), and applications in EDM, welding, electrochemistry, electronics, and scientific experiments highlight their versatility. By understanding their specifications and processing methods, users can optimize their performance for specific tasks, ensuring reliability and efficiency.