Valve cores are critical components in pneumatic and hydraulic systems, controlling fluid or gas flow in applications like automotive tires, industrial equipment, and refrigeration systems. This article provides a detailed, technical overview of valve cores, including their types, materials, specifications, and applications. It aims to deliver precise, professional insights for engineers, technicians, and industry professionals seeking a comprehensive understanding of valve core functionality and performance.

Overview of Valve Cores

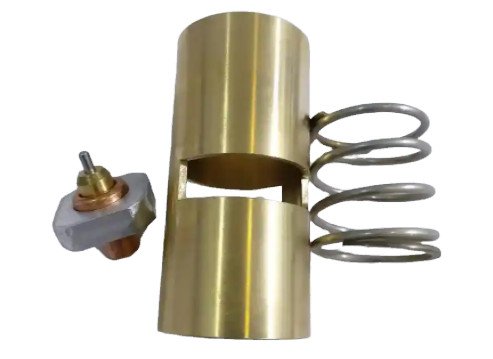

A valve core is a small, removable component within a valve stem that regulates the flow of air or fluid. It is typically a spring-assisted poppet valve designed to maintain pressure, prevent leaks, and allow controlled inflation or deflation. Valve cores are most commonly associated with tire valves but are also used in refrigeration, HVAC, and industrial fluid systems. Their design ensures reliability, ease of maintenance, and compatibility with various systems.

The primary function of a valve core is to act as a one-way valve, allowing fluid or gas to enter under external pressure while preventing unintended escape. The core's simplicity and replaceability make it a vital component in systems requiring frequent maintenance or pressure adjustments.

Types of Valve Cores

Valve cores are categorized based on their design and application. The two most prevalent types are Schrader and Presta valve cores, with specialized variants for industrial and high-pressure applications.

Schrader Valve Core

The Schrader valve core, also known as the American valve, is the most widely used type globally, found in automotive tires, motorcycle tires, and some bicycle tires. Invented in 1891 by August Schrader, it features a threaded stem with a spring-loaded poppet valve and a rubber seal to prevent leaks. Its universal design ensures compatibility with standard tools and caps.

Presta Valve Core

The Presta valve core, also called the French valve, is common in high-pressure bicycle tires and some performance vehicle applications. It is slimmer than the Schrader core, with a locknut to secure the core and a smaller rubber seal. Presta cores are designed for higher pressures and narrower rims, offering precision in pressure regulation.

Specialized Valve Cores

Specialized valve cores exist for applications like refrigeration, propane systems, and industrial fluid control. These cores may feature unique materials or configurations to handle extreme temperatures, corrosive fluids, or high pressures. For example, cores in refrigeration systems often use brass or stainless steel to resist corrosion from refrigerants.

Technical Specifications and Parameters

Valve core performance depends on precise specifications, including dimensions, pressure ratings, and material properties. The following table outlines standard parameters for Schrader and Presta valve cores, based on industry standards.

| Parameter | Schrader Valve Core | Presta Valve Core |

|---|---|---|

| Outer Diameter | 8.3 mm (standard) | 6.1 mm (standard) |

| Thread Size | 0.302-32 TPI (V1) | 0.208-36 TPI |

| Pressure Rating | Up to 300 psi (20.7 bar) | Up to 200 psi (13.8 bar) |

| Temperature Range | -40°C to 100°C | -40°C to 80°C |

| Core Length | 19-26 mm | 25-32 mm |

| Seal Material | Nitrile rubber (NBR) | Nitrile rubber or silicone |

These specifications ensure compatibility with standard tire valves and tools. Industrial valve cores may have customized dimensions or pressure ratings, often adhering to standards like ISO 9001 for quality assurance.

Materials Used in Valve Core Manufacturing

The choice of materials for valve cores is critical for durability, corrosion resistance, and performance under specific conditions. Common materials include:

- Brass: Widely used for its corrosion resistance and machinability. Standard Schrader valve cores are typically made from nickel-plated brass to enhance durability.

- Stainless Steel: Preferred for applications involving corrosive fluids or extreme temperatures, such as refrigeration or marine environments.

- Ceramics: Used in high-performance or specialized industrial applications for their wear resistance and thermal stability.

- Rubber (Seals): Nitrile rubber (NBR) is common for standard applications, while silicone or fluorocarbon (FKM) seals are used for high-temperature or chemical-resistant needs.

Material selection depends on factors like fluid compatibility, operating pressure, and environmental conditions. For example, brass cores are unsuitable for ammonia-based refrigeration systems due to corrosion risks, where stainless steel is preferred.

Manufacturing Process of Valve Cores

Valve core manufacturing involves precision engineering to ensure consistent performance and reliability. The process includes:

- Material Selection: Raw materials like brass or stainless steel are sourced and inspected for quality, adhering to standards like ASTM B16 for brass.

- Machining: Computer Numerical Control (CNC) machines shape the valve core body, including threading and poppet valve components, to precise tolerances (e.g., ±0.01 mm).

- Assembly: The poppet, spring, and rubber seal are assembled within the core body. Automated assembly ensures consistency.

- Testing: Cores undergo pressure, leak, and operational tests to verify performance. For example, Schrader cores are tested to withstand 300 psi without leakage.

- Finishing: Nickel plating or other coatings are applied to enhance corrosion resistance and durability.

Quality control is critical, with manufacturers adhering to standards like ISO 9001 to ensure reliability. Testing may include helium leak detection for high-precision applications.

Applications of Valve Cores

Valve cores are used across various industries due to their versatility and reliability. Key applications include:

Automotive and Tire Systems

Schrader valve cores are standard in car, truck, and motorcycle tires, supporting pressures up to 300 psi. They enable quick inflation and deflation while maintaining a reliable seal. Presta cores are used in high-performance bicycle tires, accommodating pressures up to 200 psi.

Refrigeration and HVAC

Valve cores in refrigeration systems control refrigerant flow, often using stainless steel to resist corrosion. They are designed for high-pressure (up to 600 psi) and low-temperature (-40°C) conditions.

Industrial Fluid Systems

In hydraulic and pneumatic systems, valve cores regulate fluid or gas flow in applications like manufacturing equipment, propane tanks, and fire extinguishers. Specialized cores may handle pressures exceeding 1000 psi.

Medical and Aerospace

Valve cores in medical devices (e.g., oxygen tanks) and aerospace systems (e.g., fuel systems) require high precision and reliability, often using ceramics or exotic alloys to meet stringent standards.

Common Issues and Considerations

While valve cores are robust, certain issues can affect performance if not addressed:

- Leaks: Worn or damaged rubber seals can cause air or fluid leaks, requiring regular inspection and replacement.

- Corrosion: Exposure to corrosive fluids or environments can degrade materials, necessitating proper material selection (e.g., stainless steel for refrigeration).

- Wear and Tear: High-pressure or frequent use can wear out springs or seals, reducing valve core lifespan.

- Clogging: Debris or contaminants in the fluid can obstruct the poppet valve, affecting flow control.

Regular maintenance, such as cleaning and timely replacement, mitigates these issues. Using high-quality cores and adhering to manufacturer specifications ensures optimal performance.

Valve Core Tools and Maintenance

Valve core maintenance requires specialized tools to ensure proper installation and removal. Common tools include:

| Tool | Description | Application |

|---|---|---|

| Valve Core Tool | A slotted or four-way tool for removing and installing valve cores. | Tire repair, HVAC maintenance |

| Valve Core Torque Tool | Applies precise torque (e.g., 0.3-0.5 Nm) to prevent over-tightening. | High-precision applications |

| Leak Detector | Uses helium or soap solution to identify leaks in valve cores. | Quality control, maintenance |

Maintenance involves inspecting seals for wear, cleaning cores to remove debris, and replacing faulty cores promptly. Proper torque application prevents damage to threads or seals during installation.

Standards and Compliance

Valve cores must adhere to industry standards to ensure safety and compatibility. Key standards include:

- ISO 9001: Quality management for manufacturing processes.

- ASTM B16: Material specifications for brass used in valve cores.

- SAE J639: Standards for refrigeration system components, including valve cores.

- ISO 5208: Testing procedures for valve leakage and performance.

Compliance with these standards ensures valve cores meet safety, reliability, and performance requirements across industries.

Conclusion

Valve cores are essential components in fluid and gas control systems, offering reliability and versatility across automotive, industrial, and specialized applications. Understanding their types, specifications, materials, and maintenance requirements is crucial for selecting the right core for specific needs. By adhering to industry standards and addressing common issues like leaks or corrosion, valve cores ensure safe and efficient system performance. This technical overview provides a systematic guide for professionals seeking to optimize valve core applications.