Valve seats are critical components in internal combustion engines, ensuring proper sealing, heat dissipation, and efficient combustion. This guide provides a detailed examination of valve seat design, materials, manufacturing processes, and technical specifications, emphasizing their role in engine performance and longevity.

Overview of Valve Seats

A valve seat is the surface in an internal combustion engine against which an intake or exhaust valve rests when closed. It forms a tight seal to maintain combustion chamber pressure, facilitates heat transfer from the valve to the cylinder head, and withstands extreme temperatures and pressures. Valve seats are typically located in the cylinder head and are either machined directly into the head or installed as separate inserts. Their design and material selection directly impact engine efficiency, power output, and durability.

The primary functions of valve seats include sealing the combustion chamber, dissipating heat from the valve, and resisting wear under high mechanical and thermal stress. Proper valve seat design ensures minimal leakage, optimal heat transfer, and consistent performance over the engine’s lifespan.

Functions of Valve Seats

Valve seats perform several essential roles in engine operation:

- Sealing the Combustion Chamber: The valve seat creates an airtight seal when the valve closes, preventing gas leakage and maintaining compression for efficient combustion.

- Heat Dissipation: Valve seats transfer heat from the valve to the cylinder head, reducing valve operating temperatures and preventing overheating, particularly for exhaust valves.

- Wear Resistance: Valve seats endure repeated valve impacts and high temperatures, requiring materials that resist wear, pitting, and recession.

- Supporting Valve Alignment: Valve seats maintain precise alignment with the valve and valve guide, ensuring consistent sealing and efficient gas flow.

These functions are critical for maintaining engine compression ratios, power output, and emission control. Improper valve seat performance can lead to reduced efficiency, increased emissions, and premature engine wear.

Types of Valve Seats

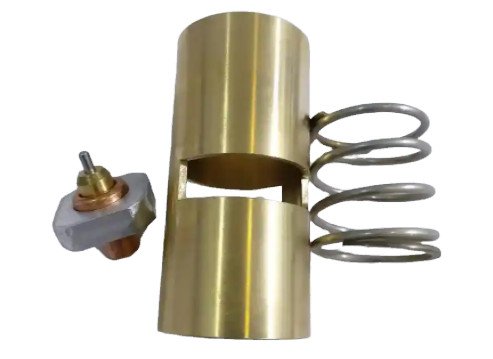

Valve seats are categorized based on their construction and integration into the engine. The two main types are integral valve seats and insert valve seats.

| Type | Description | Applications | Advantages |

|---|---|---|---|

| Integral Valve Seats | Machined directly into the cylinder head material, typically cast iron. | Older engines, low-cost applications. | Cost-effective, suitable for less demanding conditions. |

| Insert Valve Seats | Separate components pressed or shrunk into the cylinder head, made from hardened alloys. | Modern engines, high-performance, aluminum heads. | Enhanced durability, better heat resistance, replaceable. |

Insert valve seats are more common in modern engines, particularly those with aluminum cylinder heads, due to their superior durability and ability to handle extreme conditions. Integral seats are still used in some cast iron heads but are less prevalent in high-performance applications.

Valve Seat Materials

The choice of valve seat material is critical for performance and durability. Materials must withstand high temperatures, pressures, corrosion, and mechanical stress. Common materials include:

- Cast Iron: Used in older engines, cast iron offers good wear resistance and machinability but is less effective under extreme conditions.

- Alloy Steel: Provides improved heat resistance and strength, suitable for high-performance engines.

- Stellite: A cobalt-chromium alloy with excellent wear and corrosion resistance, ideal for racing and heavy-duty applications.

- Powdered Metal: Sintered materials offering high hardness and durability, widely used in modern OEM engines.

- Copper-Beryllium Alloys: High thermal conductivity for enhanced heat dissipation, often used with titanium valves.

- Nickel-Based Alloys: Resistant to high temperatures and corrosion, used in demanding environments.

Material selection depends on operating conditions, including fuel type, combustion temperature, and engine load. For example, Stellite is preferred in high-performance engines due to its ability to withstand temperatures exceeding 1,200°F (649°C).

Technical Specifications of Valve Seats

Valve seat specifications are critical for ensuring proper fit, sealing, and performance. Key parameters include geometry, material properties, and machining tolerances. Below are detailed specifications commonly used in valve seat design:

| Parameter | Specification | Description |

|---|---|---|

| Seat Angle | 30°, 45°, or 60° | The angle of the valve seat’s conical surface, typically 45° for standard engines, affects sealing and gas flow. |

| Seat Width | 1.0–2.5 mm (intake), 1.5–3.0 mm (exhaust) | Width of the contact surface between valve and seat, balancing sealing and heat transfer. |

| Interference Fit | 0.05–0.10 mm | The difference in diameter between the seat insert and cylinder head bore, ensuring secure installation. |

| Hardness | 30–35 HRC (cast iron), 35–45 HRC (Stellite) | Material hardness to resist wear and deformation. |

| Surface Finish | 15–20 microns | Smoothness of the seat surface for optimal sealing and heat transfer. |

| Concentricity | ±0.02 mm | Alignment of the valve seat with the valve guide to prevent leakage. |

These specifications ensure that valve seats meet the demands of modern engines, including high compression ratios and elevated operating temperatures. Precise machining and material selection are essential to achieve these tolerances.

Manufacturing Processes for Valve Seats

Valve seat manufacturing involves several techniques to achieve the required precision and durability:

- Press-Fitting: Insert valve seats are pressed into a machined recess in the cylinder head with a controlled interference fit to ensure stability.

- Sintering: Powdered metal seats are formed by compacting metal powders under high pressure and bonding them through a sintering process, offering customizable material properties.

- Laser Cladding: A thin layer of material is sprayed onto the cylinder head, creating a lightweight, heat-efficient seat for modern engines.

- Machining: Multi-angle cutting (e.g., three-angle cuts) is used to create precise seat geometry, typically involving a throat angle (60°), seating angle (45°), and top angle (30°) for optimal sealing and gas flow.

Each process requires strict quality control to ensure concentricity, surface finish, and dimensional accuracy. For example, sintered valve seats undergo a powder metallurgical process to achieve a density of 6.8–7.2 g/cm³, ensuring structural integrity under high stress.

Valve Seat Installation and Maintenance

Proper installation and maintenance are critical for valve seat performance. During installation, the cylinder head is counterbored to accept the seat insert with an interference fit of 0.05–0.10 mm. The seat is then pressed or shrunk into place, often using a high-temperature adhesive for added security. Machining follows to achieve the desired seat angle and width.

Maintenance involves regular inspection for signs of wear, pitting, or recession. Worn valve seats can lead to compression loss, increased emissions, and reduced power. Replacement is necessary if the seat shows cracking, burning, or excessive wear. For example, valve seat recession occurs when the seat wears down, causing the valve to sink into the cylinder head, potentially altering valve clearance by 0.5–1.0 mm.

Inspection should include checking for concentricity with the valve guide (±0.02 mm) and surface finish (15–20 microns). If the seat is integral, re-machining may be possible, but insert seats are typically replaced to restore performance.

Valve Seat Design Considerations

Designing valve seats requires balancing multiple factors to optimize engine performance:

- Material Compatibility: The seat material must be compatible with the valve material to prevent premature wear. For example, titanium valves pair well with copper-beryllium seats due to their thermal conductivity.

- Thermal Conductivity: Exhaust valve seats must dissipate heat effectively, as exhaust valves transfer up to 75% of combustion heat to the seat.

- Seat Geometry: Multi-angle designs improve gas flow and sealing. A typical three-angle cut includes a 60° throat angle, 45° seating angle, and 30° top angle.

- Fuel Type: Fuels like propane or natural gas require harder materials like Stellite to handle higher combustion temperatures.

These considerations ensure that valve seats meet the specific demands of the engine’s operating environment, from standard passenger vehicles to high-performance racing engines.

Applications of Valve Seats

Valve seats are used in various engine types, including:

- Automotive Engines: Standard gasoline and diesel engines use powdered metal or alloy steel seats for durability and cost-effectiveness.

- High-Performance Engines: Racing engines employ Stellite or copper-beryllium seats to handle extreme temperatures and stresses.

- Heavy-Duty Engines: Diesel engines in trucks and industrial equipment use hardened alloy seats to withstand high loads and prolonged operation.

- Aerospace Engines: Lightweight, heat-resistant materials like titanium are used for valve seats in aircraft engines.

Each application requires tailored material and design choices to meet specific performance requirements, such as operating temperatures up to 1,500°F (816°C) in high-performance engines.

Conclusion

Valve seats are integral to the performance and longevity of internal combustion engines. Their role in sealing, heat dissipation, and wear resistance directly impacts engine efficiency, power, and emissions. By selecting appropriate materials, adhering to precise manufacturing processes, and maintaining strict technical specifications, engineers can ensure optimal valve seat performance. Understanding these factors is essential for professionals in engine design, manufacturing, and maintenance, ensuring reliable operation across diverse applications.