Copper CNC machining is a precision manufacturing process that shapes copper and its alloys into complex components using computer-controlled tools. Known for its excellent electrical and thermal conductivity, copper is a preferred material in industries such as electronics, automotive, and aerospace. This guide provides a detailed, technical overview of copper CNC machining, focusing on processes, material grades, machining parameters, and applications, ensuring a systematic approach for professionals seeking high-quality outcomes.

Understanding Copper CNC Machining

Copper CNC machining involves using computer numerical control (CNC) systems to direct cutting tools and machinery to shape copper workpieces. Unlike manual machining, CNC systems rely on pre-programmed software to execute precise cuts, enabling the production of intricate parts with minimal human intervention. The process is ideal for creating components with tight tolerances and complex geometries, leveraging copper’s unique properties such as high conductivity and corrosion resistance.

The primary CNC techniques for copper include milling, turning, drilling, and electrical discharge machining (EDM). Each method serves specific purposes, from creating flat surfaces and slots to producing cylindrical parts or intricate details. The choice of technique depends on the component’s design, material grade, and application requirements.

Copper Grades for CNC Machining

Selecting the appropriate copper grade is critical for successful CNC machining, as different grades offer distinct properties affecting machinability, conductivity, and cost. Below is a table summarizing common copper grades used in CNC machining:

| Grade | Composition | Key Properties | Applications |

|---|---|---|---|

| C101 (Oxygen-Free) | 99.99% Cu, <0.0005% O | High electrical/thermal conductivity, excellent corrosion resistance | Electrical connectors, busbars, waveguides |

| C110 (ETP Copper) | 99.90% Cu, 50–400 ppm O | High conductivity, good machinability, ductile | Heat exchangers, electrical components |

| C145 (Tellurium Copper) | 99.0% Cu, 0.4–0.7% Te | Improved machinability, good conductivity | Fasteners, electrical switches |

| C147 (Sulfur Copper) | 99.90% Cu, 0.20–0.50% S | Excellent machinability, moderate conductivity | Crimped conductors, plumbing components |

C101 is preferred for applications requiring maximum conductivity but is challenging to machine due to its softness. C110 offers a balance of conductivity and machinability, making it versatile for various components. C145 and C147, with additives like tellurium or sulfur, enhance machinability, reducing tool wear and improving efficiency for mechanical parts.

CNC Machining Techniques for Copper

Copper’s softness and high thermal conductivity necessitate specific machining techniques to achieve precision and maintain tool life. The following sections detail the primary methods used in copper CNC machining.

CNC Milling

CNC milling uses rotary cutting tools to remove material from a copper workpiece, creating flat surfaces, slots, pockets, or complex contours. It is suitable for components like heat sinks and brackets. Key parameters include:

- Cutting Speed: 100–200 m/min for carbide tools, reduced by 15% for cast alloys with skin.

- Feed Rate: 0.05–0.15 mm/tooth to minimize heat buildup.

- Depth of Cut: 0.1–0.2 mm per pass to reduce tool stress.

- Tool Material: Carbide (N10/N20 grades) or high-speed steel (HSS) for softer alloys.

Climb milling is recommended to achieve a cleaner surface finish and improve chip evacuation, reducing the risk of material adhesion to the tool.

CNC Turning

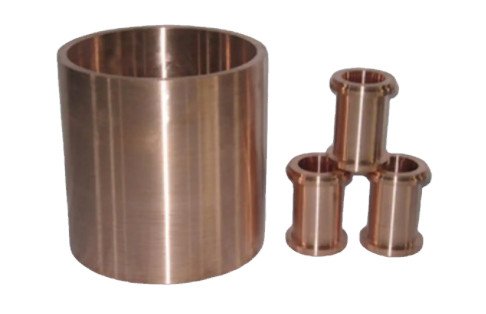

CNC turning involves rotating the copper workpiece against a stationary cutting tool to produce cylindrical parts like pins, rods, or bushings. It is ideal for components requiring precise diameters or threads. Recommended parameters include:

- Cutting Speed: 120–220 m/min, adjusted for tool material.

- Feed Rate: 0.08–0.12 mm/rev for optimal surface quality.

- Cutting Depth: 0.1–0.3 mm to minimize tool wear.

- Tool Edge Angle: 70–95°, with 90° preferred for softer copper to reduce smearing.

Maintaining a constant cutting depth and using tools with larger rake angles helps manage cutting forces and heat, extending tool life.

Electrical Discharge Machining (EDM)

EDM uses electrical sparks to erode material, making it suitable for intricate shapes or thin walls where traditional cutting tools may struggle. It is slower but effective for complex components like RF components. Key considerations include:

- Electrode Material: Graphite or copper for high precision.

- Dielectric Fluid: Oil-based fluids to control spark and flush debris.

- Pulse Duration: 10–100 microseconds for fine surface finishes.

EDM avoids mechanical stress, making it ideal for delicate copper parts but requires careful setup to maintain efficiency.

Swiss Machining

Swiss machining is used for small, high-precision parts with tight tolerances, common in medical and electronics applications. The workpiece is supported close to the cutting tool, minimizing deflection. Parameters include:

- Spindle Speed: 2,000–6,000 RPM, depending on part diameter.

- Feed Rate: 0.02–0.08 mm/rev for precision.

- Tool Material: Coated carbide for durability.

Swiss machining excels in producing long, slender copper components with consistent accuracy.

Machining Parameters and Tool Selection

Optimizing machining parameters and tool selection is essential for efficient copper CNC machining. Copper’s softness can lead to tool adhesion and burr formation, requiring careful control of cutting conditions. The following table outlines recommended parameters for milling and turning:

| Process | Tool Material | Cutting Speed (m/min) | Feed Rate (mm/rev or mm/tooth) | Depth of Cut (mm) |

|---|---|---|---|---|

| Milling | Carbide (N10/N20) | 100–200 | 0.05–0.15 | 0.1–0.2 |

| Turning | HSS or Carbide | 120–220 | 0.08–0.12 | 0.1–0.3 |

Tool Selection: Carbide tools with coatings (e.g., TiN or diamond-like carbon) reduce wear and improve chip evacuation. For softer copper grades, tools with a sharp cutting edge and near-90° edge angles minimize smearing. High-pressure coolant systems, using emulsified oils or low-viscosity oils, are critical for lubrication and chip removal, preventing adhesion in the cutting zone.

Design Considerations for Copper CNC Machining

Designing parts for copper CNC machining requires adherence to Design for Manufacturability (DFM) principles to optimize efficiency and reduce costs. Key considerations include:

- Minimize Deep Pockets: Deep cuts increase chip accumulation, complicating evacuation.

- Maintain Wall Thickness: Keep walls at least 0.5 mm thick to prevent vibration and distortion.

- Add Fillets: Rounded corners reduce tool stress and improve finish quality.

- Optimize Tolerances: Avoid overly tight tolerances (e.g., ±0.01 mm) unless essential, as copper’s softness makes precision challenging.

- Size Limitations: For milling, parts up to 1200 x 500 x 152 mm; for turning, up to 152 x 394 mm.

These practices streamline machining, reduce tool wear, and ensure consistent part quality.

Surface Finishing for Copper Parts

Post-processing enhances the aesthetics and functionality of machined copper parts. Common finishing techniques include:

- Electropolishing: Removes 0.0025–0.064 mm of surface material, improving corrosion resistance and gloss for medical or food-grade components.

- Electroplating: Applies a thin metal layer (e.g., tin) to enhance solderability or durability without compromising conductivity.

- Media Blasting: Uses abrasive materials like glass beads to create a uniform matte finish, concealing minor surface imperfections.

Smaller nose radii on tools and wiper inserts during machining can further improve surface finish by reducing feed marks and smearing.

Applications of Copper CNC Machining

Copper’s properties make it indispensable in various industries. Common applications include:

- Electronics: Busbars, connectors, and circuit board components due to high electrical conductivity.

- Automotive: Heat exchangers and EV battery terminals for thermal management.

- Aerospace: RF components and waveguides requiring precision and conductivity.

- Medical: Surgical tools and implants leveraging copper’s antibacterial properties.

Each application demands specific machining techniques and grades to meet performance requirements.

FAQ

What copper grade is best for CNC machining?

C145 (tellurium copper) is often preferred for its improved machinability while maintaining good conductivity. C110 is also widely used for its balance of properties.

What tools are recommended for machining copper?

Carbide tools with coatings or HSS tools with sharp edges are ideal. Use near-90° edge angles for softer grades to reduce smearing.

How does coolant affect copper CNC machining?

High-pressure coolant, such as emulsified or low-viscosity oils, lubricates the cutting zone, reduces tool adhesion, and improves chip evacuation.