Precision machining technology is a cornerstone of modern manufacturing, enabling the production of intricate components with exceptional accuracy. This field encompasses advanced techniques, specialized equipment, and stringent quality controls to meet the demands of industries such as aerospace, automotive, medical, and electronics. In this detailed guide, we delve into the core aspects of precision machining technology, offering a systematic exploration of its processes, tools, applications, and technical parameters. Whether you are an engineer, manufacturer, or industry enthusiast, this article provides valuable insights into the world of high-precision manufacturing.

Understanding Precision Machining Technology

Precision machining technology refers to manufacturing processes that create parts and components with extremely tight tolerances, often in the range of micrometers. This technology relies on computer numerical control (CNC) systems, advanced cutting tools, and meticulous measurement techniques to achieve unparalleled accuracy. Unlike conventional machining, precision machining focuses on producing complex geometries and fine surface finishes that are critical for high-performance applications.

The primary goal of precision machining is to ensure that every produced part meets exact specifications without deviation. This is achieved through a combination of automated machinery, skilled operators, and rigorous quality assurance protocols. Industries that depend on this technology often require components that can withstand extreme conditions, such as high pressure, temperature, or wear, making precision a non-negotiable factor.

Key Processes in Precision Machining

Precision machining encompasses several specialized processes, each tailored to specific materials, geometries, and tolerances. Below, we outline the most common techniques used in this field, highlighting their technical aspects and applications.

CNC Milling

CNC milling involves the use of rotating cutting tools to remove material from a workpiece, creating complex shapes and features. This process is ideal for producing parts with intricate designs, such as slots, holes, and contours. Modern CNC milling machines operate with multi-axis capabilities (3-axis, 4-axis, or 5-axis), allowing for greater flexibility and precision. Typical tolerances for CNC milling can range from ±0.005 mm to ±0.01 mm, depending on the machine and material.

CNC Turning

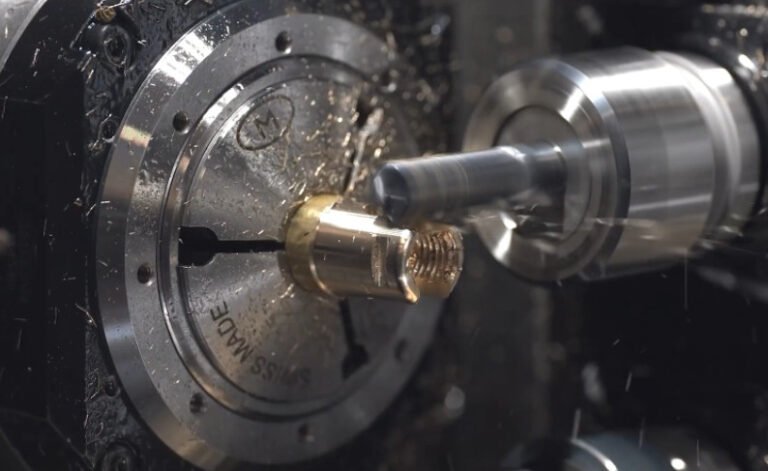

CNC turning is a process where a workpiece rotates while a cutting tool removes material to create cylindrical or conical shapes. This technique is commonly used for producing shafts, pins, and other rotational components. Precision turning machines can achieve surface finishes as fine as Ra 0.4 µm and tolerances of ±0.002 mm, making them indispensable in high-accuracy manufacturing.

Grinding

Grinding is a finishing process that uses abrasive wheels to achieve ultra-smooth surfaces and tight tolerances. It is often employed after initial machining to refine dimensions and improve surface quality. Precision grinding can achieve tolerances as low as ±0.001 mm, and it is widely used in the production of tools, dies, and bearings.

Electrical Discharge Machining (EDM)

EDM is a non-traditional machining process that uses electrical sparks to erode material from a workpiece. It is particularly effective for hard materials like titanium and hardened steel, where conventional cutting tools may fail. EDM can achieve intricate shapes with tolerances of ±0.005 mm, making it a preferred method for mold and die manufacturing.

Materials Used in Precision Machining

The choice of material plays a critical role in precision machining, as it affects tool selection, machining parameters, and final product performance. Common materials include metals, plastics, and composites, each with unique properties that influence the machining process.

Metals such as aluminum, stainless steel, and titanium are frequently used due to their strength and durability. Aluminum, for instance, is lightweight and easy to machine, with a tensile strength of approximately 310 MPa for 6061-T6 alloy. Stainless steel offers corrosion resistance, with grades like 316 providing a yield strength of 290 MPa. Titanium, known for its high strength-to-weight ratio (around 860 MPa for Ti-6Al-4V), is often used in aerospace applications but requires specialized tools due to its hardness.

Plastics like PEEK and PTFE are also machined for applications requiring chemical resistance or low friction. These materials typically have lower tensile strengths (around 100 MPa for PEEK) but offer unique advantages in medical and electrical industries. Composites, such as carbon fiber-reinforced polymers, are increasingly used for lightweight, high-strength components, though they demand specialized cutting techniques to prevent delamination.

Essential Tools and Equipment

Precision machining relies on a range of advanced tools and equipment designed to deliver consistent results. CNC machines, equipped with high-speed spindles and precise linear guides, form the backbone of this technology. Spindle speeds can range from 10,000 to 30,000 RPM, depending on the material and application, while linear accuracy can be as high as 0.002 mm per meter.

Cutting tools are another critical component, often made from carbide, ceramic, or diamond-coated materials to withstand high temperatures and wear. For example, carbide end mills with a hardness of 90 HRA are commonly used for milling steel, while diamond tools are preferred for non-ferrous materials like aluminum to achieve mirror-like finishes.

Measurement and inspection tools, such as coordinate measuring machines (CMM) and laser scanners, ensure that finished parts meet specifications. A typical CMM can measure dimensions with an accuracy of ±0.001 mm, providing detailed data on geometry and surface characteristics.

Applications Across Industries

Precision machining technology serves a wide array of industries, each with unique requirements for accuracy and performance. In the aerospace sector, components like turbine blades and structural parts must adhere to tolerances of ±0.01 mm to ensure safety and efficiency. Materials such as titanium and Inconel are commonly used, requiring advanced machining techniques to handle their high strength and heat resistance.

The automotive industry relies on precision machining for engine components, transmission parts, and braking systems. Tolerances for critical parts, such as pistons and crankshafts, often fall within ±0.005 mm to guarantee optimal performance and fuel efficiency.

In the medical field, precision machining produces surgical instruments, implants, and diagnostic equipment. For instance, orthopedic implants made from titanium or cobalt-chrome alloys require surface finishes of Ra 0.2 µm or better to ensure biocompatibility and patient safety.

Electronics manufacturing also benefits from precision machining, particularly in the production of connectors, enclosures, and heat sinks. Tolerances as tight as ±0.002 mm are often necessary to ensure proper fit and thermal management in compact devices.

Technical Parameters and Specifications

To illustrate the level of detail in precision machining, the following table provides an overview of typical tolerances and surface finishes for common processes. These parameters are critical for ensuring that components meet design requirements and function as intended.

| Process | Tolerance (mm) | Surface Finish (Ra, µm) | Common Materials |

|---|---|---|---|

| CNC Milling | ±0.005 to ±0.01 | 0.8 - 1.6 | Aluminum, Steel, Titanium |

| CNC Turning | ±0.002 to ±0.005 | 0.4 - 0.8 | Stainless Steel, Brass |

| Grinding | ±0.001 | 0.2 - 0.4 | Hardened Steel, Ceramics |

| EDM | ±0.005 | 0.8 - 1.2 | Titanium, Tool Steel |

Quality Control in Precision Machining

Quality control is a fundamental aspect of precision machining, ensuring that every part meets the required standards. This involves multiple stages of inspection, from raw material verification to final product testing. Techniques such as statistical process control (SPC) are used to monitor machining parameters in real-time, detecting deviations before they result in defects.

Advanced metrology tools, including optical comparators and surface profilometers, are employed to measure dimensions and surface characteristics. For example, a surface profilometer can assess roughness with a resolution of 0.01 µm, providing precise data for quality assurance. Additionally, non-destructive testing (NDT) methods, such as ultrasonic testing, are used to detect internal flaws in critical components.

Documentation and traceability are also essential, particularly in industries like aerospace and medical manufacturing. Every step of the machining process is recorded, from tool settings to inspection results, ensuring full accountability and compliance with standards like ISO 9001.