Aluminum oxide (Al₂O₃), commonly known as alumina, is a chemical compound of aluminum and oxygen widely recognized for its exceptional material properties. This article provides a comprehensive overview of aluminum oxide, detailing its physical and chemical characteristics, production methods, and diverse industrial applications. With a focus on technical precision, the content is structured to deliver clear, systematic information for professionals and researchers in materials science and related fields.

Chemical and Physical Properties of Aluminum Oxide

Aluminum oxide is an amphoteric oxide with the chemical formula Al₂O₃, exhibiting a unique combination of properties that make it indispensable across industries. Its crystalline structure, primarily occurring as corundum (α-Al₂O₃), contributes to its durability and versatility. Below are the key properties that define its utility:

- Hardness: Aluminume oxide has a Mohs hardness of 9, making it one of the hardest naturally occurring materials, second only to diamond (Mohs 10).

- Thermal Stability: It has a melting point of 2,072°C (3,762°F) and a boiling point of 2,977°C (5,391°F), enabling its use in high-temperature environments.

- Chemical Inertness: Al₂O₃ is highly resistant to corrosion, with solubility in water less than 0.0001 g/100 mL at room temperature. It resists most acids and alkalis, though it can react with hydrofluoric acid and strong bases like sodium hydroxide.

- Electrical Insulation: With a dielectric strength of approximately 15 kV/mm and low electrical conductivity, it is an excellent insulator for electronic applications.

- Thermal Conductivity: For a ceramic material, alumina has a relatively high thermal conductivity of 30 W/m·K, suitable for heat-dissipating components.

- Density: Its density ranges from 3.95 to 4.1 g/cm³, depending on the crystalline form and purity.

These properties stem from its strong ionic-covalent bonding and hexagonal close-packed crystal structure in the α-phase, which is the most thermodynamically stable polymorph. Other metastable phases, such as gamma (γ-Al₂O₃), exhibit higher surface areas, making them suitable for catalytic applications.

Production Methods of Aluminum Oxide

Aluminum oxide is primarily produced from bauxite ore through the Bayer process, followed by calcination. The production process is critical to achieving the desired purity and crystalline form for specific applications. The steps are outlined below:

- Mining and Preparation: Bauxite, containing hydrous aluminume oxides (e.g., gibbsite, boehmite), is mined and crushed into a fine powder.

- Digestion: The bauxite is mixed with a hot sodium hydroxide (NaOH) solution at 150–250°C and 20 atm pressure, dissolving aluminum oxide as sodium aluminate while leaving impurities like iron oxides behind.

- Clarification: Solid impurities are filtered out, producing a clear sodium aluminate solution.

- Precipitation: The solution’s pH is lowered using carbon dioxide (CO₂), precipitating aluminum hydroxide (Al(OH)₃).

- Calcination: Aluminum hydroxide is heated at 1,100–1,200°C to produce anhydrous alumina (Al₂O₃) as a fine white powder.

For high-purity applications, additional refining steps, such as chemical vapor deposition (CVD) or plasma electrolytic oxidation, may be employed to achieve ultra-high purity levels (up to 99.99%). Fused alumina, used in abrasives, is produced by melting bauxite in an electric arc furnace and cooling it to form a hard, crystalline material.

| Process Step | Temperature (°C) | Pressure (atm) | Output |

|---|---|---|---|

| Digestion | 150–250 | 20 | Sodium aluminate solution |

| Calcination | 1,100–1,200 | 1 | Anhydrous Al₂O₃ |

Industrial Applications of Aluminum Oxide

Aluminum oxide’s unique properties enable its use across a wide range of industries. Its applications are categorized below based on its primary characteristics:

Abrasives and Cutting Tools

Due to its hardness (Mohs 9) and toughness, aluminume oxide is a preferred material for abrasives. It is used in:

- Sandpaper and Grinding Wheels: Available in grit sizes ranging from 16 to 240, alumina is ideal for grinding metals, wood, and glass.

- Polishing Compounds: Fine-grain alumina is used in lapping operations and dental polishing to remove stains.

- Cutting Tools: Alumina-based ceramics, sometimes reinforced with zirconia, are used for industrial cutting tools due to their wear resistance.

Refractories and High-Temperature Applications

The high melting point (2,072°C) and thermal stability of alumina make it a key material for refractory applications, including:

- Furnace Linings: Alumina lines kilns, incinerators, and reactors, withstanding temperatures up to 1,800°C in continuous operation.

- Crucibles: Used in metal and glass production, alumina crucibles maintain structural integrity at high temperatures.

Electronics and Electrical Insulation

Alumina’s electrical insulation properties (dielectric strength: 15 kV/mm) and thermal conductivity (30 W/m·K) are critical for:

- Circuit Substrates: Alumina is used in integrated circuits and semiconductor packaging due to its insulating properties.

- High-Voltage Insulators: Employed in spark plugs and high-voltage devices, alumina ensures reliable performance under electrical stress.

Medical and Bioceramic Applications

Aluminum oxide’s biocompatibility and mechanical strength make it suitable for medical applications, such as:

- Orthopedic Implants: High-purity alumina (approved by the FDA in 2000) is used in hip replacement bearings and dental implants.

- Tissue Reinforcement: Porous alumina supports tissue growth in bionic implants.

Catalysis and Chemical Processing

Gamma-alumina, with its high surface area, is used as a catalyst or catalyst support in:

- Claus Process: Converts hydrogen sulfide to elemental sulfur in refineries.

- Dehydration Reactions: Facilitates the conversion of alcohols to alkenes.

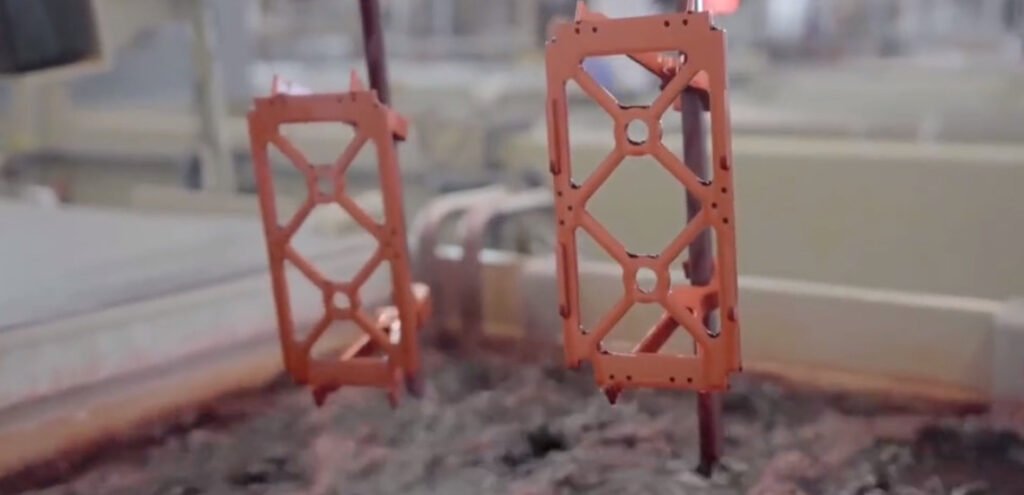

Protective Coatings and Armor

Alumina’s hardness and chemical inertness are leveraged in:

- Anodizing: A thin layer of aluminum oxide (4 nm) forms naturally on aluminum surfaces, preventing corrosion. Anodizing enhances this layer’s thickness and durability.

- Ballistic Armor: Alumina ceramic plates, often combined with aramid or UHMWPE, provide protection against rifle threats.

Safety and Environmental Considerations

While aluminume oxide is generally non-toxic and chemically inert, certain safety considerations arise during its production and use:

- Inhalation Risks: Fine alumina dust can cause respiratory irritation or long-term lung issues if inhaled in high concentrations. Proper ventilation and respiratory protection are recommended in industrial settings.

- Environmental Impact: The Bayer process generates red mud, a caustic byproduct that requires careful waste management to prevent environmental contamination.

These considerations highlight the need for controlled handling and sustainable production practices to minimize health and environmental risks.

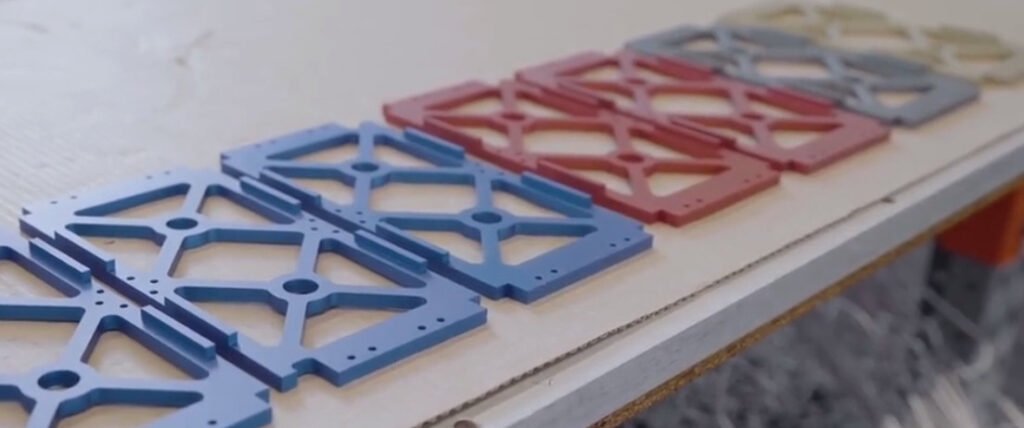

Comparison of Aluminum Oxide Forms

Aluminum oxide exists in multiple forms, each suited to specific applications. The table below compares the key forms:

| Form | Crystal Structure | Key Properties | Primary Applications |

|---|---|---|---|

| Alpha (α-Al₂O₃) | Hexagonal | High hardness, thermal stability | Abrasives, refractories, ceramics |

| Gamma (γ-Al₂O₃) | Cubic | High surface area, lower hardness | Catalysis, adsorbents |

Conclusion

Aluminum oxide (Al₂O₃) is a cornerstone material in modern industry, valued for its hardness, thermal stability, chemical inertness, and electrical insulation properties. Its production, primarily via the Bayer process, supports a wide range of applications, from abrasives and refractories to electronics and medical implants. By understanding its properties, production methods, and applications, industries can leverage alumina’s versatility to meet diverse technical requirements. Proper handling and waste management are essential to ensure safe and sustainable use of this critical material.