Bearing sleeves, also known as plain bearings or bushings, are essential components in mechanical systems, designed to reduce friction, support rotating shafts, and ensure operational stability. This article provides a comprehensive overview of their structure, types, materials, applications, and manufacturing processes, offering technical insights for engineers and professionals. The content is structured systematically to address key aspects of bearing sleeves, focusing on their design and performance.

Structure and Characteristics

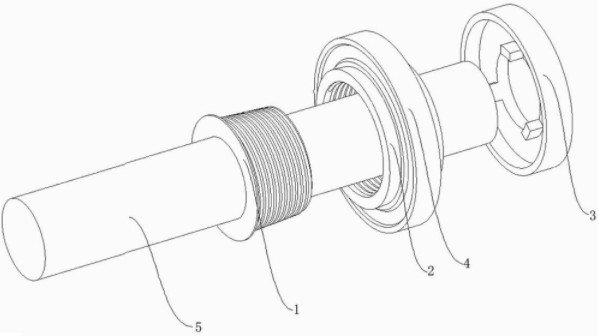

Bearing sleeves feature a simple, hollow cylindrical design resembling a sleeve, with a thin-walled structure that reduces manufacturing costs and simplifies installation and maintenance. Their key characteristics include:

- Simple Design: The tubular shape minimizes material use and enables easy integration into various systems.

- Varied Dimensions: Available in a wide range of inner diameters (ID: 5 mm to 500 mm), outer diameters (OD: per ISO H7 tolerances), and lengths (1.5 to 3 times the shaft diameter) to suit diverse applications.

- Material Diversity: Constructed from metals (e.g., steel, bronze), polymers (e.g., PTFE, nylon), or composites, each offering specific properties like durability, corrosion resistance, or low friction.

These characteristics make bearing sleeves versatile, cost-effective, and adaptable to specific operational requirements.

Types of Bearing Sleeves

Bearing sleeves are categorized by material and function, each tailored to specific operating conditions. The following table summarizes their types and properties:

| Type | Material/Function | Applications | Key Properties |

|---|---|---|---|

| Steel Sleeve | High-carbon or alloy steel (e.g., AISI 1045). | Industrial machinery, heavy equipment. | High strength, wear resistance, 100 MPa load capacity. |

| Bronze Sleeve | Copper-tin alloy (80% Cu, 10% Sn). | Marine, hydraulic systems. | Corrosion resistance, anti-seizure, 80 MPa load capacity. |

| Polymer Sleeve | PTFE, nylon, or PEEK (50-150 MPa tensile strength). | Electronics, medical devices. | Low friction (0.05-0.2 coefficient), self-lubricating. |

| Composite Sleeve | Metal-polymer hybrids. | Aerospace, automotive. | Combines strength, low friction, fatigue resistance. |

| Self-Lubricating Sleeve | Embedded lubricants (e.g., graphite, PTFE). | Food processing, remote systems. | Maintenance-free, long-term stability. |

| Insulated Sleeve | Polymer or ceramic-coated materials. | Electrical motors, generators. | Prevents electrical corrosion, high insulation. |

Each type is selected based on load, speed, and environmental factors, ensuring compatibility with specific applications.

Materials of Bearing Sleeves

The material of a bearing sleeve determines its performance under specific conditions. Common materials include:

- Steel: High-carbon or alloy steel (e.g., AISI 4140) provides high strength and wear resistance, suitable for high-load (up to 100 MPa) and high-speed (PV: 5-10 MPa·m/s) applications.

- Bronze: Typically 80% copper and 10% tin, offering corrosion resistance and excellent anti-seizure properties for medium-load (up to 80 MPa) and corrosive environments.

- Polymers: Materials like PTFE, nylon, or PEEK have low friction coefficients (0.05-0.2), self-lubrication, and chemical stability, ideal for light-load (10-50 MPa) and clean environments.

- Composites: Combine metal and polymer properties, offering balanced strength, low friction, and fatigue resistance for demanding applications like aerospace.

- Sintered Metals: Porous bronze or iron structures hold lubricants, enabling self-lubrication for maintenance-free operation.

Material selection considers operating temperature (-40°C to 250°C for polymers, up to 400°C for metals), load, and environmental exposure (e.g., moisture, chemicals).

Functions of Bearing Sleeves

Bearing sleeves serve multiple critical functions in mechanical systems:

- Friction and Wear Reduction: Act as an intermediate layer, converting sliding friction to smoother sliding or rolling friction, reducing wear and improving efficiency. Friction coefficients range from 0.05 (lubricated) to 0.2 (dry).

- Support and Positioning: Provide precise support for rotating shafts, ensuring rotational accuracy and minimizing vibration. Tolerances adhere to ISO G6/H7 standards.

- Error Compensation: Accommodate manufacturing or installation errors (e.g., 0.01-0.05 mm) and compensate for thermal expansion or deformation during operation.

- Sealing and Protection: Prevent lubricant leakage and block contaminants like dust or water, protecting the shaft and bearing surfaces. Some designs incorporate seals for enhanced protection.

These functions enhance equipment reliability and longevity across various applications.

Applications of Bearing Sleeves

Bearing sleeves are widely used across industries due to their versatility and reliability. Key applications include:

- Industrial Machinery: Support transmission and gear shafts in machine tools, printing presses, textile machines, and cranes, ensuring precision and durability under loads up to 100 MPa.

- Automotive: Used in engines (crankshaft, connecting rod sleeves), transmissions, and wheel hubs, reducing friction and enhancing reliability. Bronze sleeves handle loads up to 50 MPa.

- Aerospace: Employed in engines, landing gear, and control systems, requiring lightweight, high-strength sleeves (e.g., composites) for temperatures from -50°C to 200°C.

- Home Appliances: Support motor and compressor shafts in washing machines, refrigerators, and air conditioners, ensuring quiet operation and low maintenance.

- Marine: Polymer or bronze sleeves resist corrosion in propeller shafts and rudders, operating in saltwater environments.

Each application demands specific sleeve types and materials to meet performance requirements.

Manufacturing Processes

The production of bearing sleeves involves precise manufacturing processes to ensure dimensional accuracy, surface quality, and material performance. Common processes include:

- Casting: Used for bronze sleeves, where molten metal is poured into molds to form the cylindrical shape. Centrifugal casting ensures uniform wall thickness (1-10 mm) and high density.

- Machining: Steel and bronze sleeves are machined using CNC lathes or milling machines to achieve precise IDs and ODs (tolerances: ±0.01 mm) and surface finishes (Ra 0.4-1.6 µm).

- Injection Molding: Polymer sleeves (e.g., PTFE, nylon) are produced via injection molding, allowing complex shapes and consistent dimensions for high-volume production.

- Sintering: Sintered metal sleeves are made by compacting powdered bronze or iron and heating it below the melting point to form a porous structure for lubricant retention.

- Surface Treatment: Includes coating (e.g., PTFE or molybdenum disulfide for low friction) or heat treatment (e.g., quenching steel to 50-60 HRC) to enhance durability.

Manufacturing adheres to standards like DIN 1850 or ASTM B438, ensuring consistent quality. Quality control involves dimensional checks, surface roughness testing, and material property verification.

Selection Criteria

Selecting the right bearing sleeve requires evaluating multiple factors. The following table outlines key considerations:

| Criteria | Considerations | Example |

|---|---|---|

| Load | Radial/axial, static/dynamic, up to 100 MPa. | Steel sleeve for 80 MPa radial load. |

| Speed | PV value (1-10 MPa·m/s), RPM (1000-5000). | PTFE sleeve for 2 MPa·m/s. |

| Environment | Temperature (-50°C to 400°C), corrosion. | Bronze sleeve for marine use. |

| Maintenance | Lubrication needs, accessibility. | Self-lubricating sleeve for remote systems. |

Balancing these factors ensures optimal performance and cost-effectiveness.

Installation and Maintenance

Proper installation and maintenance are critical for bearing sleeve performance:

- Installation: Use press-fit techniques (ISO H7/s6 tolerances) to ensure alignment (misalignment <0.05 mm). Apply initial lubrication to prevent dry running.

- Maintenance: Inspect for wear (max 0.1-0.2 mm), replenish lubricants (e.g., ISO VG 32-68 oil or NLGI 1-3 grease), and replace worn sleeves. Self-lubricating sleeves require minimal upkeep.

Regular maintenance extends service life and prevents system failures.

Performance Testing

Bearing sleeves undergo rigorous testing to ensure reliability:

- Wear Testing: Per ASTM G77, measures material loss under specific loads and speeds.

- Load Testing: Per DIN 1850, verifies maximum load capacity (e.g., 100 MPa for steel).

- Friction Testing: Evaluates friction coefficients (0.05-0.2 for lubricated sleeves) under operating conditions.

Testing ensures compliance with standards like ISO 4379, guaranteeing consistent performance.

Conclusion

Bearing sleeves are vital for reducing friction, supporting shafts, and ensuring operational stability across industries. Their simple design, diverse materials, and precise manufacturing processes make them adaptable to various applications. By understanding their structure, types, functions, and selection criteria, engineers can optimize performance and reliability. This guide provides a technical foundation for implementing bearing sleeves effectively.

FAQs About Bearing Sleeves

What is a bearing sleeve?

A bearing sleeve, also known as a bearing bushing or sleeve bearing, is a cylindrical component designed to reduce friction between a rotating shaft and its housing. It acts as a low-friction interface, supporting the shaft’s movement while minimizing wear on both the shaft and the surrounding structure. Unlike rolling-element bearings (e.g., ball bearings), sleeve bearings rely on sliding friction and are often made from materials like bronze, brass, plastic, or self-lubricating composites.

When should I use a bearing sleeve instead of a rolling bearing?

Cost is a concern: They are generally cheaper to manufacture than rolling bearings.

Noise reduction is critical: Sliding friction produces less noise than rolling elements.

High loads or slow speeds are involved: They handle heavy radial loads better at low rotational speeds.

Space is limited: Their compact, cylindrical design fits into tight assemblies.

Lubrication access is poor: Self-lubricating sleeves eliminate the need for frequent maintenance.

Can bearing sleeves be customized?

Yes, many manufacturers offer custom bearing sleeves tailored to specific dimensions, materials, or performance requirements (e.g., flanged designs for axial positioning, or special coatings for enhanced wear resistance).