Coordinate Measuring Machine (CMM) inspection is a high-precision, automated technology used to measure the geometric characteristics of manufactured parts, ensuring compliance with design specifications. By capturing three-dimensional coordinates of a part’s surface, CMMs evaluate dimensions, shapes, and positional tolerances. Widely used in industries such as automotive, aerospace, and medical device manufacturing, CMM inspection is a cornerstone of quality assurance in precision manufacturing. This article provides a detailed, technical overview of CMM principles, types, processes, applications, advantages, limitations, and key parameters.

Core Principles of CMM Inspection

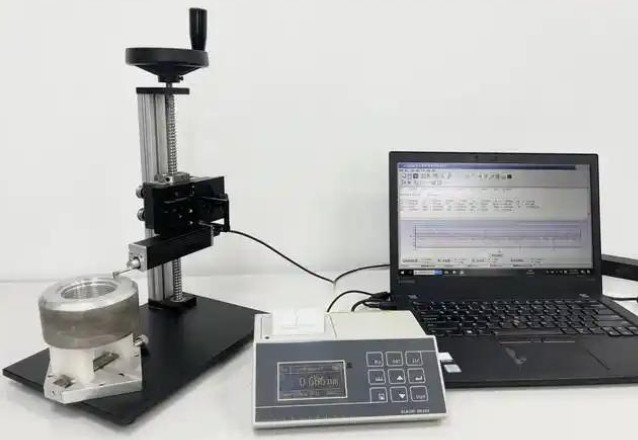

CMM inspection operates on the principle of coordinate metrology, utilizing a three-dimensional Cartesian coordinate system (X, Y, Z) to define the position of points on a part’s surface. A probing system—either contact-based (e.g., tactile probes) or non-contact (e.g., laser or optical sensors)—collects coordinate data. These data points form a point cloud that represents the part’s geometry.

The collected coordinates are processed by specialized software, which compares them to a theoretical model, typically a CAD file, to assess dimensional accuracy and geometric tolerances. Deviations are calculated to determine if the part meets specifications, such as dimensional tolerances (e.g., ±0.01 mm) or geometric dimensioning and tolerancing (GD&T) requirements, including flatness, concentricity, or perpendicularity. The precision of CMMs, often reaching 0.1-5 µm, makes them ideal for high-accuracy applications.

Main Functions of CMM Inspection

CMM inspection serves multiple purposes in quality control, enabling comprehensive evaluation of manufactured parts. Its primary functions include:

- Dimensional Measurement: Measures basic dimensions such as length, diameter, distance, and angles with accuracies of 1-10 µm.

- Geometric Tolerancing: Evaluates shape tolerances (e.g., straightness, flatness, roundness, cylindricity) and positional tolerances (e.g., parallelism, perpendicularity, concentricity, position) within tolerances as tight as 0.01-0.05 mm.

- Complex Surface Measurement: Captures data from freeform surfaces (e.g., turbine blades, car body panels) by collecting thousands of points and comparing them to CAD models, achieving surface deviation accuracies of 5-20 µm.

- Reverse Engineering Support: Generates point clouds to reconstruct 3D models of existing parts, aiding redesign or replication with point cloud densities up to 10,000 points per square centimeter.

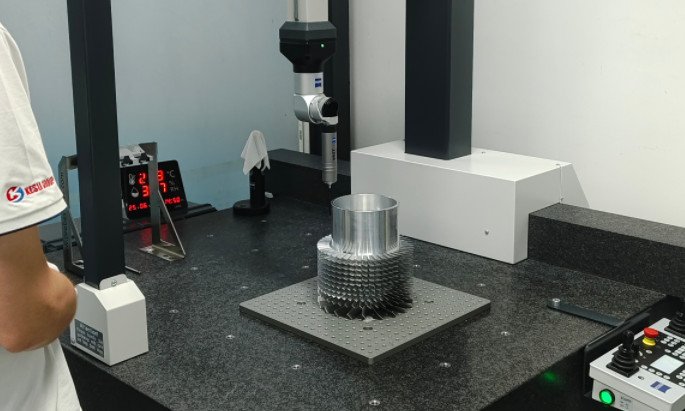

Types of Coordinate Measuring Machines

CMMs are available in various configurations, each designed for specific measurement tasks based on part size, complexity, and environmental constraints. The following table summarizes the main types:

| Type | Features | Typical Applications | Accuracy Range |

|---|---|---|---|

| Bridge CMM | Stable structure, large measurement range (up to several meters) | Large parts (e.g., automotive chassis, machine tool beds) | 1-5 µm |

| Cantilever CMM | Flexible operation, ideal for side measurements | Small to medium parts (e.g., electronic components, molds) | 5-10 µm |

| Gantry CMM | High rigidity, suited for heavy workpieces | Aerospace components, large molds | 5-15 µm |

| Articulating Arm CMM | Portable, suitable for on-site measurements, lower accuracy | Complex structures, assembly line inspections | 20-50 µm |

Each type is selected based on the part’s characteristics and measurement environment. For instance, bridge CMMs are preferred for high-precision tasks in controlled settings, while articulating arm CMMs are used for flexible, on-site inspections.

CMM Inspection Process

The CMM inspection process is systematic, ensuring accurate and repeatable results. The key steps are:

- Workpiece Preparation: The part is cleaned and securely fixtured on the CMM table to prevent movement, minimizing positional errors to less than 1 µm.

- Coordinate System Alignment: Reference points (e.g., holes, edges) are measured to align the part’s coordinate system with the CMM’s, ensuring consistency with design benchmarks.

- Measurement Execution:

- Automated Measurement: A pre-programmed measurement path, often generated from a CAD model, guides the probe to collect 100-10,000 points at speeds of 100-800 mm/s.

- Manual Measurement: The operator manually positions the probe for simple parts or ad-hoc inspections, suitable for low-volume tasks.

- Data Processing: Software calculates deviations between measured and theoretical values, analyzing GD&T parameters (e.g., flatness: 0.01-0.05 mm, concentricity: 0.02-0.1 mm) and generating detailed reports with tolerance bands and out-of-specification alerts.

- Result Evaluation: The report is reviewed to determine part compliance, with results fed back to production for process adjustments.

Advantages and Limitations of CMM Inspection

CMM inspection offers significant benefits but also has inherent limitations. These are outlined below:

| Aspect | Details | Technical Parameters |

|---|---|---|

| Advantages |

| Accuracy: 0.1-5 µm; Point collection rate: 100-10,000 points/s |

| Limitations |

| Temperature stability: ±0.5°C; Measurement time: 1-30 min/part |

Applications of CMM Inspection

CMM inspection is critical across multiple industries, ensuring precision and compliance with stringent standards:

- Automotive Industry: Measures engine components, transmission housings, and body panels with tolerances of 10-20 µm to ensure fit and performance.

- Aerospace: Inspects turbine blades, airframes, and structural components with accuracies of 5-10 µm to meet safety and regulatory requirements (e.g., AS9100).

- Mold Manufacturing: Verifies mold cavities and cores for surface accuracy within 5-15 µm, ensuring high-quality production.

- Medical Devices: Ensures dimensional control of implants and surgical tools with sub-micron precision for biocompatibility and functionality.

- Electronics: Measures semiconductor packages and precision connectors with tolerances of 10-50 µm for reliable performance.

Technical Parameters of CMM Inspection

CMM performance is defined by key technical parameters that determine its suitability for specific tasks:

- Accuracy: Maximum permissible error, typically 1-20 µm, depending on CMM type.

- Repeatability: Consistency of measurements, ranging from 0.5-5 µm.

- Measurement Volume: Ranges from 0.5 m³ for small parts to 50 m³ for large components.

- Probe Resolution: Smallest detectable change, typically 0.1-1 µm.

- Scanning Speed: Data collection rate, typically 100-800 mm/s, affecting inspection time.

These parameters guide CMM selection, ensuring alignment with application requirements, such as high-precision aerospace parts or large-scale automotive components.

Standards and Compliance

CMM inspection adheres to international standards to ensure measurement reliability and traceability:

- ISO 10360: Defines performance criteria for CMM accuracy and repeatability, ensuring consistent results across systems.

- AS9100: Aerospace standard mandating CMM use for first article inspections and quality control.

- ISO 9001: General quality management standard requiring accurate measurement processes.

Compliance with these standards minimizes non-conformance risks and supports regulatory requirements in high-stakes industries.

Selecting a CMM System

Choosing the right CMM involves evaluating several factors:

- Part Characteristics: Size and complexity dictate CMM type (e.g., gantry for large parts, articulating arm for complex geometries).

- Accuracy Needs: Applications requiring 1-5 µm accuracy favor bridge or gantry CMMs.

- Environmental Conditions: Controlled environments (temperature: 20±0.5°C, vibration-free) are necessary for high-precision CMMs.

- Software Compatibility: Must support CAD formats (e.g., STEP, IGES) and GD&T analysis for comprehensive reporting.

Engaging with certified CMM suppliers and verifying their adherence to ISO standards ensures reliable system performance.

Conclusion

CMM inspection is a vital technology for ensuring precision and quality in modern manufacturing. By leveraging advanced probing systems, robust software, and precise mechanical structures, CMMs deliver unparalleled accuracy and automation. Their applications span automotive, aerospace, medical, and electronics industries, supporting dimensional control, geometric tolerancing, and reverse engineering. Despite limitations such as high costs and environmental sensitivity, CMMs remain indispensable for meeting stringent quality standards and ensuring product reliability.