CNC Swiss screw machining stands as a cornerstone in the world of precision manufacturing, offering unparalleled accuracy and efficiency for producing complex, small to medium-sized components. This specialized machining process, often referred to as Swiss-style turning, is widely utilized across industries such as medical, aerospace, automotive, and electronics, where tight tolerances and intricate designs are non-negotiable. In this comprehensive guide, we delve into the intricacies of CNC Swiss screw machining, exploring its key features, benefits, applications, and technical specifications to provide a thorough understanding of its role in modern manufacturing.

What is CNC Swiss Screw Machining?

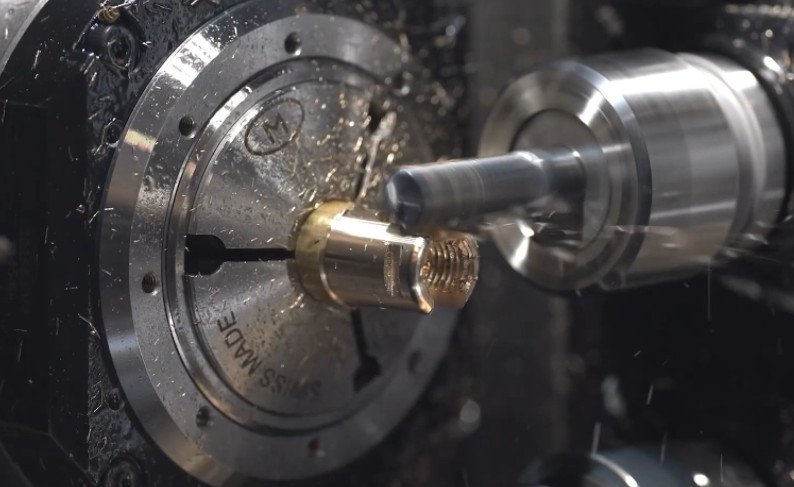

CNC Swiss screw machining is a highly specialized form of CNC (Computer Numerical Control) turning that originated in Switzerland for the production of small, precise watch components. Unlike traditional lathes, Swiss screw machines are designed to handle long, slender workpieces with exceptional accuracy. The process involves a sliding headstock and guide bushing that support the material close to the cutting tool, minimizing deflection and vibration during machining. This setup allows for the production of intricate parts with tight tolerances, often in a single setup.

The CNC aspect of Swiss screw machining integrates advanced computer programming to control multiple axes simultaneously, enabling the creation of complex geometries with minimal human intervention. Modern Swiss screw machines can operate with up to 12 axes, incorporating live tooling for milling, drilling, and threading operations, all within the same cycle. This capability significantly reduces production time and enhances precision, making it ideal for high-volume manufacturing of small, detailed components.

Key Features of CNC Swiss Screw Machining

CNC Swiss screw machining is distinguished by several unique features that set it apart from other machining processes. These features contribute to its reputation as a go-to solution for precision manufacturing:

- High Precision: Swiss screw machines can achieve tolerances as tight as ±0.0002 inches (±0.005 mm), making them suitable for applications where even the slightest deviation is unacceptable.

- Guide Bushing Support: The guide bushing holds the workpiece close to the cutting tool, ensuring stability and reducing deflection, especially for long, thin parts with length-to-diameter ratios up to 20:1.

- Multi-Axis Capability: Modern machines support simultaneous operations across multiple axes, allowing for complex geometries and secondary operations like milling and drilling in a single setup.

- High-Speed Production: Swiss screw machines are optimized for high-volume runs, with spindle speeds often ranging from 6,000 to 12,000 RPM, ensuring rapid cycle times.

- Material Versatility: These machines can process a wide range of materials, including stainless steel, titanium, aluminum, brass, and various plastics, catering to diverse industry needs.

These features collectively enable manufacturers to produce intricate components with consistent quality, even in large quantities, while maintaining cost efficiency.

Benefits of CNC Swiss Screw Machining

The advantages of CNC Swiss screw machining extend beyond precision, offering manufacturers a range of operational and economic benefits. Here’s a detailed look at why this technology is a preferred choice for precision component production:

First, the process excels in producing parts with exceptional accuracy and repeatability. The close proximity of the guide bushing to the cutting tool minimizes errors caused by material deflection, ensuring that each part meets exact specifications. This is particularly critical in industries like medical device manufacturing, where components such as surgical implants must adhere to stringent dimensional standards.

Second, CNC Swiss screw machining supports high-volume production with reduced cycle times. The ability to perform multiple operations—turning, milling, drilling, and threading—in a single setup eliminates the need for secondary processes, streamlining workflows and reducing lead times. For instance, a typical Swiss screw machine can produce up to 1,000 parts per hour, depending on complexity and material.

Third, the technology is highly cost-effective for complex parts. By minimizing material waste through precise cutting and reducing labor costs with automated operations, manufacturers can achieve significant savings, especially in large production runs. Additionally, the durability of modern Swiss screw machines ensures long-term reliability, with many models boasting operational lifespans exceeding 10 years with proper maintenance.

Finally, the versatility of CNC Swiss screw machining allows it to handle a wide array of materials and part sizes. Whether it’s crafting micro-components for electronics with diameters as small as 0.5 mm or producing larger automotive parts up to 32 mm in diameter, this process adapts to varying requirements with ease.

Applications of CNC Swiss Screw Machining

CNC Swiss screw machining serves a broad spectrum of industries, each benefiting from its ability to produce high-precision components. Below are some of the primary applications where this technology plays a pivotal role:

In the medical industry, Swiss screw machining is indispensable for manufacturing components like bone screws, dental implants, and surgical instruments. These parts often require biocompatible materials such as titanium or stainless steel, with tolerances as tight as ±0.0005 inches (±0.0127 mm) to ensure patient safety and device functionality.

The aerospace sector relies on Swiss screw machining for producing critical components such as fasteners, hydraulic fittings, and sensor housings. These parts must withstand extreme conditions, requiring materials like Inconel or high-grade aluminum, machined to exact specifications for reliability and performance.

In the automotive industry, Swiss screw machining is used to create precision parts like fuel injector components, transmission pins, and valve stems. The high-volume capabilities of Swiss machines meet the industry’s demand for large-scale production without compromising on quality.

Lastly, the electronics industry benefits from Swiss screw machining for producing connectors, pins, and micro-components used in circuit boards and devices. The ability to work with small diameters and conductive materials like copper or brass makes this process ideal for intricate electronic applications.

Technical Specifications and Parameters

Understanding the technical parameters of CNC Swiss screw machining is essential for selecting the right equipment and ensuring optimal performance. Below is a detailed table summarizing common specifications for Swiss screw machines used in precision manufacturing:

| Parameter | Typical Range | Description |

|---|---|---|

| Maximum Bar Diameter | 0.5 mm to 32 mm | Range of workpiece diameters the machine can handle. |

| Spindle Speed | 6,000 to 12,000 RPM | Speed at which the spindle rotates for cutting operations. |

| Tolerance Capability | ±0.0002 to ±0.001 inches | Precision level achievable for part dimensions. |

| Number of Axes | 5 to 12 axes | Number of controlled axes for simultaneous operations. |

| Length-to-Diameter Ratio | Up to 20:1 | Ability to machine long, slender parts without deflection. |

These parameters can vary depending on the machine model and manufacturer, but they provide a baseline for understanding the capabilities of CNC Swiss screw machining. When selecting a machine, factors such as material type, part complexity, and production volume should also be considered to ensure compatibility with specific project requirements.

Materials Compatible with CNC Swiss Screw Machining

One of the standout features of CNC Swiss screw machining is its ability to process a diverse range of materials, catering to the unique needs of different industries. Commonly machined materials include:

- Stainless Steel: Grades like 304, 316, and 17-4 PH are frequently used for medical and aerospace components due to their corrosion resistance and strength.

- Titanium: Often used in medical implants and aerospace parts for its lightweight properties and biocompatibility, despite being challenging to machine.

- Aluminum: Popular in automotive and electronics for its lightweight and excellent machinability, with common grades including 6061 and 7075.

- Brass and Copper: Widely used in electronics for conductivity, with Swiss machining ensuring precise dimensions for connectors and terminals.

- Plastics: Materials like PEEK and Delrin are machined for medical and industrial applications where lightweight, non-conductive parts are needed.

The choice of material depends on the application, with factors such as strength, weight, corrosion resistance, and machinability playing a critical role. CNC Swiss screw machines are equipped with specialized tooling and cutting parameters to handle these materials efficiently, ensuring high-quality results regardless of the material’s properties.

Conclusion

CNC Swiss screw machining represents the pinnacle of precision manufacturing, offering unmatched accuracy, efficiency, and versatility for producing complex components across various industries. Its ability to handle tight tolerances, high-volume production, and a wide range of materials makes it an indispensable technology for modern manufacturers. By understanding its features, benefits, applications, and technical specifications, businesses can leverage CNC Swiss screw machining to meet the most demanding production requirements. Whether you’re in the medical, aerospace, automotive, or electronics sector, this advanced machining process provides the reliability and precision needed to stay competitive in today’s market.