Hardness measurement is a fundamental process in materials science, engineering, and manufacturing, used to evaluate a material's resistance to deformation, indentation, scratching, or penetration by an external force. This property is critical as it often correlates with mechanical attributes such as strength, wear resistance, and durability. This article provides a detailed, technical exploration of the primary hardness testing methods—Rockwell, Brinell, Vickers, Knoop, and Shore—detailing their principles, parameters, procedures, and applications. The content is structured systematically to ensure clarity and precision for professionals and researchers.

Principles of Hardness Measurement

Hardness measurement involves applying a controlled force, known as the load, to a material’s surface using a specific indenter—a hard tool with a defined geometry, such as a diamond, steel ball, or tungsten carbide ball. The resulting indentation’s characteristics (e.g., depth, diameter, or diagonal length) are measured to calculate the hardness value. The relationship between the applied load and the indentation’s size or shape determines the material’s hardness, expressed in standardized units or scales specific to each testing method. Hardness testing is essential for assessing material suitability in applications requiring durability, wear resistance, or structural integrity.

Rockwell Hardness Test

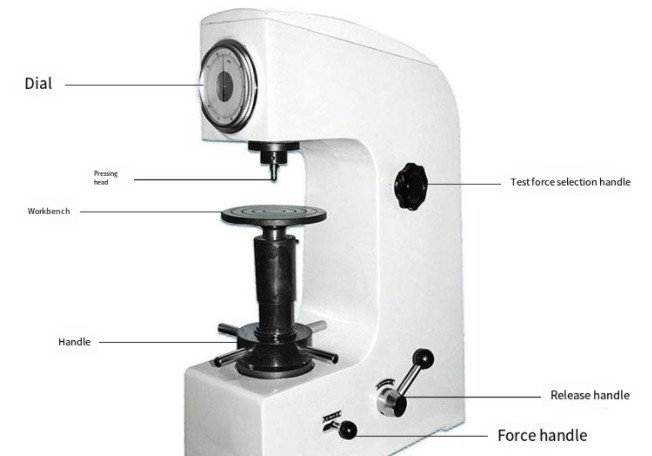

The Rockwell hardness test is widely used due to its speed, simplicity, and direct readout of hardness values. It measures the depth of indentation created by a two-step loading process: a minor load (typically 10 kgf) to set the indenter, followed by a major load (60, 100, or 150 kgf) to create the indentation. The indenter is either a diamond cone for harder materials or a steel ball (1/16" or 1/8" diameter) for softer ones. The hardness value is expressed on scales such as HRA, HRB, or HRC, depending on the indenter and load used.

The test is standardized under ASTM E18 and ISO 6508. The hardness number (HR) is calculated based on the difference in indentation depth between the minor and major loads, with higher values indicating harder materials. For example, HRC is commonly used for hardened steels, while HRB is suited for softer metals like aluminum.

| Parameter | Value |

|---|---|

| Minor Load | 10 kgf |

| Major Load | 60, 100, or 150 kgf |

| Indenter Types | Diamond cone, 1/16" or 1/8" steel ball |

| Scales | HRA, HRB, HRC, etc. |

| Typical Materials | Steel, aluminum, alloys |

The Rockwell test is ideal for quality control in manufacturing due to its rapid results and minimal sample preparation. However, surface irregularities or thin samples can affect accuracy, requiring careful preparation and calibration.

Brinell Hardness Test

The Brinell hardness test is suited for soft to medium-hard metals and materials with coarse or inhomogeneous structures, such as cast iron or aluminum alloys. It uses a spherical indenter, typically a tungsten carbide ball, to create a large indentation under a constant load (500–3000 kgf). The diameter of the indentation is measured optically, and the hardness (HBW) is calculated using the formula: HBW = (2F) / (πD(D - √(D² - d²))), where F is the load (kgf), D is the indenter diameter (mm), and d is the indentation diameter (mm).

Standardized under ASTM E10 and ISO 6506, the Brinell test is effective for large samples due to its large indentation size, which averages out material inconsistencies. Common indenter diameters are 1, 2.5, 5, or 10 mm, with loads adjusted to maintain a consistent load-to-diameter ratio.

| Parameter | Value |

|---|---|

| Load Range | 500–3000 kgf |

| Indenter Diameter | 1, 2.5, 5, or 10 mm |

| Formula | HBW = (2F) / (πD(D - √(D² - d²))) |

| Typical Materials | Cast iron, non-ferrous metals |

The Brinell test’s large indentation makes it less sensitive to surface imperfections but unsuitable for thin or very hard materials due to the high loads required. Optical measurement equipment adds complexity to the process.

Vickers Hardness Test

The Vickers hardness test is highly versatile, applicable to a wide range of materials, from soft metals to hard ceramics, due to its adjustable load range (1 gf to 100 kgf). It uses a square-based diamond pyramid indenter to create a precise indentation. The hardness (HV) is calculated by measuring the average diagonal length of the indentation under a microscope, using the formula: HV = 1.854 * (F / d²), where F is the load (kgf) and d is the average diagonal length (mm).

Standardized under ISO 6507 and ASTM E92, the Vickers test is ideal for microhardness testing (low loads for thin coatings or small parts) and macrohardness testing (higher loads for bulk materials). Its single hardness scale simplifies comparisons across materials. For example, Vickers is preferred for testing brittle ceramics due to its precise indentation geometry.

The test requires careful surface preparation and skilled operators for accurate diagonal measurements. Its precision makes it valuable for research and development but increases testing time compared to Rockwell.

Knoop Hardness Test

The Knoop hardness test is a microhardness method designed for brittle materials (e.g., ceramics, glass) and thin coatings. It uses an elongated, rhombus-shaped diamond indenter to create a shallow indentation, minimizing material damage. The hardness (HK) is calculated based on the longer diagonal of the indentation, using the formula: HK = 14.229 * (F / d²), where F is the load (kgf) and d is the long diagonal length (mm).

Loads typically range from 10 gf to 1 kgf, making Knoop ideal for small or thin samples, such as jewelry or electronic components. Standardized under ASTM E384, the test requires high-magnification optical measurement and meticulous surface preparation to ensure accuracy. Its shallow indentation depth makes it suitable for materials prone to cracking but sensitive to surface conditions.

Shore Hardness Test

The Shore hardness test is primarily used for non-metallic materials, such as rubbers, plastics, and elastomers. It employs a spring-loaded indenter to measure either the indentation depth or the rebound of the indenter under a light load. The test is conducted using a durometer, with results expressed on scales like Shore A (for soft rubbers) or Shore D (for hard plastics).

Standardized under ASTM D2240, the Shore test is quick and portable, making it ideal for on-site quality control in industries like tire manufacturing or polymer production. The indenter’s geometry and spring force are tailored to the material’s elasticity. For example, Shore A uses a truncated cone indenter for softer materials, while Shore D uses a sharper point for harder plastics. The test is less precise for metals and requires calibration to ensure consistent results.

Applications of Hardness Testing

Hardness testing is critical across various industries for ensuring material performance and reliability. In manufacturing, it is used for quality control to verify that components, such as steel gears or aluminum castings, meet hardness specifications. In material selection, hardness data guides the choice of wear-resistant alloys for machinery or durable coatings for aerospace components. In research and development, hardness testing characterizes the mechanical behavior of new materials, such as advanced ceramics or composites, aiding in their development for specific applications.

For example, Rockwell testing ensures the hardness of hardened steel tools, Brinell testing verifies the integrity of cast iron components, Vickers testing assesses thin coatings in electronics, Knoop testing evaluates brittle ceramics in medical implants, and Shore testing confirms the elasticity of rubber seals in automotive applications.

Key Terminology

Understanding hardness testing requires familiarity with key terms:

- Indenter: A hard tool (e.g., diamond, steel ball, tungsten carbide ball) used to create an indentation on the material’s surface.

- Load: The force applied to the indenter, ranging from a few grams (microhardness tests) to hundreds of kilograms (macrohardness tests).

- Indentation: The mark left on the material’s surface after applying the load, used to calculate hardness based on its depth, diameter, or diagonal length.

Example: Vickers hardness measurement is preferred for testing brittle materials like ceramics due to its precise indentation geometry.

Considerations in Hardness Testing

Accurate hardness testing requires attention to several factors. Surface preparation is critical, as roughness, oxides, or contaminants can distort indentation measurements, particularly in Vickers and Knoop tests. Sample thickness must be sufficient to avoid substrate effects—typically 10 times the indentation depth for Rockwell and Brinell, and 2–3 times for Vickers and Knoop. Equipment calibration using standardized test blocks is essential to ensure precision.

Operator skill is crucial, especially for tests requiring optical measurements (e.g., Brinell, Vickers, Knoop), as errors in measuring indentation dimensions can lead to inaccurate results. Environmental factors, such as temperature or vibration, can also affect outcomes, necessitating controlled testing conditions. Selecting the appropriate test method and parameters for the material and application is vital to obtain reliable data.

Conclusion

Hardness measurement is a cornerstone of material characterization, providing essential data on a material’s resistance to deformation. The Rockwell, Brinell, Vickers, Knoop, and Shore tests each offer unique capabilities tailored to specific materials and applications, from metals and ceramics to rubbers and plastics. By understanding their principles, parameters, and practical considerations, professionals can select the most suitable method for accurate and reliable results, supporting quality control, material selection, and research across industries.