A valve stem is a critical component in various mechanical systems, particularly in automotive, industrial, and plumbing applications. It serves as the interface between the valve and the actuating mechanism, enabling precise control of fluid or gas flow. This guide provides a detailed, technical overview of valve stems, including their types, materials, specifications, maintenance, and applications. Designed for professionals and engineers, this resource emphasizes clarity, precision, and systematic organization to ensure practical utility.

Definition and Function of Valve Stems

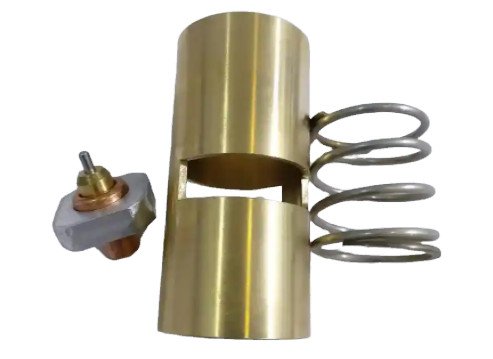

A valve stem is a slender, cylindrical component that connects the valve head to the actuator or control mechanism. Its primary function is to transmit motion from the actuator (manual, pneumatic, hydraulic, or electric) to the valve, enabling the opening, closing, or modulation of flow. In automotive applications, valve stems are best known for their role in tire pressure maintenance, while in industrial settings, they are integral to gate, globe, ball, and butterfly valves.

Valve stems must withstand mechanical stress, corrosion, and wear while maintaining precise alignment and sealing integrity. Their design varies based on the valve type, application, and operating environment, making them essential for system reliability.

Types of Valve Stems

Valve stems are categorized based on their design, application, and movement. The following table outlines the primary types and their characteristics.

| Type | Description | Applications | Key Features |

|---|---|---|---|

| Rising Stem | Stem moves upward as the valve opens, providing visible indication of valve position. | Gate valves, globe valves | Linear motion, high visibility, requires vertical space |

| Non-Rising Stem | Stem rotates without vertical movement, threaded internally. | Gate valves in confined spaces | Compact design, less maintenance |

| Rotary Stem | Stem rotates to actuate the valve, typically 90 degrees. | Ball valves, butterfly valves | Quick operation, low torque |

| Tire Valve Stem | Small stem for inflating and sealing tires. | Automotive tires | Schrader or Presta types, rubber or metal |

Each type is engineered for specific operational requirements, such as space constraints, actuation speed, or environmental conditions.

Materials Used in Valve Stems

The material selection for valve stems depends on factors like operating pressure, temperature, fluid compatibility, and corrosion resistance. Common materials include:

- Stainless Steel (e.g., 316, 304): Offers excellent corrosion resistance and durability. Suitable for chemical processing and marine environments. Tensile strength: 515-690 MPa.

- Carbon Steel: Cost-effective for low-corrosion environments. Used in oil and gas applications. Yield strength: 250-400 MPa.

- Brass: Common in automotive tire valve stems and low-pressure plumbing. Corrosion-resistant to water and air. Tensile strength: 300-500 MPa.

- Inconel: High-temperature and corrosion-resistant alloy for extreme environments, such as aerospace or high-pressure steam systems. Tensile strength: 700-1000 MPa.

- Titanium: Lightweight, high-strength, and corrosion-resistant. Used in aerospace and chemical industries. Tensile strength: 900-1100 MPa.

Material selection impacts cost, longevity, and maintenance requirements. For example, stainless steel is preferred in corrosive environments, while carbon steel suits budget-conscious applications with minimal chemical exposure.

Technical Specifications and Parameters

Valve stem design requires precise specifications to ensure compatibility and performance. Key parameters include:

- Diameter: Typically ranges from 6 mm to 50 mm, depending on valve size and application. Smaller diameters (e.g., 6-12 mm) are common in tire valve stems, while larger diameters (20-50 mm) are used in industrial valves.

- Length: Varies from 20 mm (tire valves) to over 500 mm (large gate valves). Length affects actuator travel and system clearance.

- Thread Specifications: Threads (e.g., M8x1.25, 1/2-13 UNC) ensure secure connection to actuators. Pitch and thread form must match mating components.

- Surface Finish: Measured in Ra (micrometers). A finish of 0.8-1.6 Ra minimizes friction and wear in dynamic applications.

- Pressure Rating: Stems must withstand pressures from 0.1 MPa (tire valves) to 100 MPa (high-pressure industrial valves).

- Temperature Range: Materials must operate within -40°C to 600°C, depending on the application (e.g., cryogenic systems vs. high-temperature steam).

These parameters are specified during design to meet standards like ASME B16.34, API 600, or ISO 17292, ensuring interoperability and safety.

Manufacturing Processes

Valve stems are manufactured using precision processes to achieve tight tolerances and durability. Common methods include:

- CNC Machining: Used for high-precision threading and shaping. Tolerances as low as ±0.01 mm ensure fit and function.

- Forging: Enhances strength by aligning grain structure. Common for high-pressure stems in industrial valves.

- Surface Treatment: Processes like nitriding or chrome plating improve wear resistance and reduce friction. Hardness: 50-60 HRC post-treatment.

- Quality Control: Non-destructive testing (e.g., ultrasonic, magnetic particle) ensures defect-free stems. Dimensional checks verify compliance with specifications.

Manufacturing processes are selected based on material, application, and cost considerations, with CNC machining being the most common for custom stems.

Maintenance and Inspection

Regular maintenance extends valve stem life and prevents system failures. Key practices include:

- Lubrication: Apply silicone or graphite-based lubricants to reduce friction in rising and rotary stems. Frequency: every 6-12 months, depending on usage.

- Inspection: Check for wear, corrosion, or bending. Use calipers for dimensional checks and visual inspection for surface damage.

- Seal Replacement: Replace stem seals (e.g., O-rings, packing glands) if leaks are detected. Common materials: PTFE, graphite.

- Alignment Verification: Ensure stem alignment with actuator to prevent binding. Misalignment tolerance: <0.1 mm.

Maintenance schedules depend on operating conditions. High-pressure or high-temperature environments require more frequent inspections.

Applications Across Industries

Valve stems are used in diverse sectors, each with unique requirements. The following table summarizes key applications.

| Industry | Valve Stem Type | Typical Materials | Operating Conditions |

|---|---|---|---|

| Automotive | Tire valve stem | Brass, rubber | 0.1-0.7 MPa, -40°C to 80°C |

| Oil and Gas | Rising, non-rising | Stainless steel, carbon steel | 1-100 MPa, -20°C to 200°C |

| Chemical Processing | Rotary, rising | Stainless steel, Inconel | 0.5-50 MPa, -40°C to 400°C |

| Aerospace | Rotary | Titanium, Inconel | 10-70 MPa, -50°C to 600°C |

Each industry demands specific stem designs to handle unique pressures, temperatures, and media, ensuring operational efficiency and safety.

Design Considerations

Effective valve stem design requires balancing functionality, durability, and cost. Key considerations include:

- Load Capacity: Stems must resist bending and shear forces. Calculated using material yield strength and safety factors (e.g., 1.5-2.0).

- Corrosion Resistance: Select materials compatible with the medium (e.g., acids, water, gases). Corrosion rate: <0.1 mm/year for optimal materials.

- Sealing Integrity: Ensure tight seals with packing or O-rings to prevent leaks. Leakage rate: <0.01 cm³/s under rated pressure.

- Actuator Compatibility: Match stem threading and dimensions to actuator specifications for smooth operation.

These considerations ensure reliability and compliance with industry standards, minimizing downtime and maintenance costs.

Common Issues and Solutions

While valve stems are robust, specific issues can arise. Below are common problems and their solutions:

- Corrosion: Caused by exposure to aggressive media. Solution: Use corrosion-resistant materials (e.g., 316 stainless steel) or apply coatings.

- Wear and Friction: Occurs in high-cycle applications. Solution: Apply surface treatments (e.g., nitriding) and regular lubrication.

- Leakage: Results from worn seals or misalignment. Solution: Replace seals and verify alignment during maintenance.

- Bending: Due to excessive load or misalignment. Solution: Ensure proper load calculations and actuator alignment.

Proactive maintenance and material selection mitigate these issues, ensuring long-term performance.

Standards and Compliance

Valve stems must comply with industry standards to ensure safety and interoperability. Key standards include:

- ASME B16.34: Specifies materials, dimensions, and testing for valves and stems.

- API 600: Covers steel gate valves, including stem design requirements.

- ISO 17292: Governs ball valves, including rotary stem specifications.

- ISO 5211: Defines actuator mounting dimensions for stem compatibility.

Compliance ensures stems meet performance and safety requirements across global markets.

Conclusion

Valve stems are vital components in controlling fluid and gas flow across automotive, industrial, and aerospace applications. Their design, material selection, and maintenance directly impact system reliability and efficiency. By understanding types, specifications, and best practices, engineers and technicians can optimize performance and minimize issues. This guide provides a systematic, technical resource for professionals seeking to enhance their knowledge and application of valve stems.