Dat Nguyen CNC represents a benchmark in the field of precision machining and custom manufacturing. With a focus on delivering high-quality CNC (Computer Numerical Control) solutions, Dat Nguyen CNC caters to a wide range of industries, including automotive, aerospace, medical, and industrial equipment. This comprehensive guide delves into the intricacies of CNC machining under the expertise of Dat Nguyen CNC, offering detailed insights into processes, parameters, and applications. Whether you're a manufacturer seeking reliable machining services or an engineer exploring technical specifications, this resource provides a thorough understanding of what sets Dat Nguyen CNC apart in the competitive world of precision engineering.

Understanding CNC Machining with Dat Nguyen CNC

CNC machining is a manufacturing process that utilizes computer-controlled tools to create precise components from raw materials such as metals, plastics, and composites. At Dat Nguyen CNC, the process is elevated through advanced machinery, skilled technicians, and a commitment to quality. The core principle of CNC machining lies in its ability to automate complex tasks, ensuring repeatability and accuracy down to micrometer levels. This section explores the fundamental aspects of CNC machining as practiced by Dat Nguyen CNC, including the types of machines used, materials processed, and industries served.

The CNC machines at Dat Nguyen CNC include 3-axis, 4-axis, and 5-axis milling machines, as well as CNC lathes and turning centers. These machines are equipped with state-of-the-art control systems, allowing for intricate designs and tight tolerances. For instance, a typical 5-axis CNC machine can achieve positional accuracy of ±0.005 mm, making it ideal for complex geometries in aerospace components. The materials processed range from aluminum (6061, 7075 grades) and stainless steel (304, 316 grades) to specialized alloys like titanium and Inconel, each selected based on the application’s strength, corrosion resistance, and thermal properties.

Key Processes in Dat Nguyen CNC Operations

The operations at Dat Nguyen CNC encompass a variety of machining processes tailored to meet specific project requirements. These processes include milling, turning, drilling, and grinding, each executed with precision to ensure optimal results. Milling, for instance, involves the use of rotary cutters to remove material from a workpiece, creating slots, holes, and contours. At Dat Nguyen CNC, milling operations are performed with spindle speeds ranging from 8,000 to 24,000 RPM, depending on the material and tool specifications, ensuring efficient material removal rates.

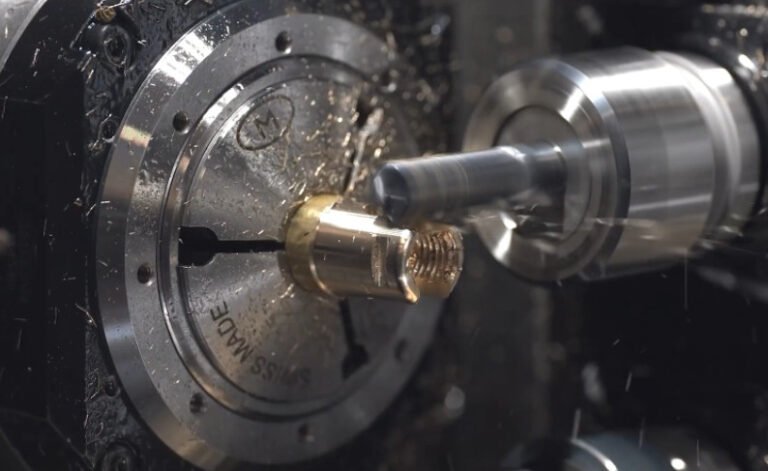

Turning, another critical process, is conducted on CNC lathes to produce cylindrical parts such as shafts and bushings. The lathes at Dat Nguyen CNC feature live tooling capabilities, enabling simultaneous milling and turning operations, which reduce production time. Drilling and grinding further complement these processes by providing precise hole-making and surface finishing, respectively. For example, surface grinding at Dat Nguyen CNC achieves a surface roughness of Ra 0.2 µm, meeting stringent requirements for medical device components.

Technical Parameters and Specifications at Dat Nguyen CNC

Precision in CNC machining is heavily reliant on adhering to strict technical parameters and specifications. At Dat Nguyen CNC, every project is governed by detailed guidelines to ensure consistency and quality. Below is a table summarizing key machining parameters commonly applied in their operations:

| Parameter | Range/Value | Application |

|---|---|---|

| Tolerance | ±0.002 mm to ±0.01 mm | High-precision components |

| Spindle Speed | 8,000 - 24,000 RPM | Milling and drilling |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm | Medical and aerospace parts |

| Material Hardness | Up to 65 HRC | Hardened steel and alloys |

These parameters are adjusted based on the material properties and design requirements of each project. For instance, when machining titanium, lower cutting speeds (around 60-80 m/min) and specific coolant types are used to manage heat generation and tool wear. This level of detail ensures that components meet or exceed client expectations in terms of dimensional accuracy and surface quality.

Applications of Dat Nguyen CNC Services

The versatility of CNC machining at Dat Nguyen CNC allows for a broad spectrum of applications across multiple industries. In the automotive sector, Dat Nguyen CNC produces engine components, transmission parts, and suspension elements with tight tolerances to withstand high stress and temperature conditions. For example, aluminum engine blocks are machined with a dimensional tolerance of ±0.005 mm to ensure perfect alignment and performance.

In the aerospace industry, lightweight yet durable materials like titanium are machined into structural components and fasteners. These parts often require complex geometries, which are efficiently handled by 5-axis CNC machines. The medical industry benefits from Dat Nguyen CNC’s expertise in producing surgical instruments and implants, where biocompatibility and precision are paramount. Stainless steel 316L, commonly used for implants, is machined to achieve a mirror-like finish (Ra 0.2 µm) to minimize bacterial adhesion.

Additionally, Dat Nguyen CNC serves the industrial equipment sector by manufacturing custom gears, valves, and fittings. These components often require high wear resistance and are made from hardened steels or specialized coatings to extend service life. Each application is approached with a tailored strategy to optimize production efficiency while maintaining quality standards.

Quality Assurance and Testing at Dat Nguyen CNC

Quality assurance is a cornerstone of Dat Nguyen CNC’s operations. Every component undergoes rigorous inspection using advanced metrology equipment such as Coordinate Measuring Machines (CMM), optical comparators, and surface profilometers. The CMM, for instance, provides measurement accuracy of ±0.001 mm, ensuring that even the smallest deviations are detected and corrected.

Testing protocols include dimensional checks, surface finish analysis, and material composition verification. For critical applications, such as aerospace parts, additional non-destructive testing (NDT) methods like ultrasonic testing are employed to detect internal flaws. Dat Nguyen CNC also adheres to international standards such as ISO 9001 for quality management, ensuring that every process, from raw material procurement to final delivery, is systematically controlled.

Custom Solutions and Client Collaboration

One of the defining features of Dat Nguyen CNC is its ability to provide customized machining solutions. Clients are involved at every stage of the process, from initial design consultation to final production. This collaborative approach ensures that specific requirements, such as unique geometries or material preferences, are fully integrated into the manufacturing process.

For instance, when working on a bespoke project for a medical device manufacturer, Dat Nguyen CNC engineers use CAD/CAM software to simulate machining paths and identify potential issues before production begins. This preemptive analysis reduces lead times and minimizes errors. Clients also benefit from detailed progress reports and access to real-time data on project milestones, fostering transparency and trust.

Environmental Responsibility in Machining

Dat Nguyen CNC is committed to sustainable manufacturing practices. This includes the efficient use of resources, recycling of scrap materials, and the implementation of energy-saving technologies in their facilities. Cutting fluids and coolants are carefully selected to minimize environmental impact, and waste materials such as metal chips are processed for reuse in secondary industries. These efforts reflect a balance between industrial productivity and ecological responsibility, ensuring that precision machining does not come at the expense of the environment.