Electrical Discharge Machining (EDM) is a highly specialized manufacturing process used to shape hard metals and materials that are difficult to machine with traditional methods. As industries demand greater precision and complex geometries, the role of electrical discharge machining manufacturers becomes increasingly vital. These manufacturers provide advanced EDM solutions, catering to sectors like aerospace, automotive, medical, and tool-making. This comprehensive guide explores the world of EDM manufacturers, delving into their capabilities, technologies, applications, and key considerations for selecting the right partner for your machining needs.

What is Electrical Discharge Machining?

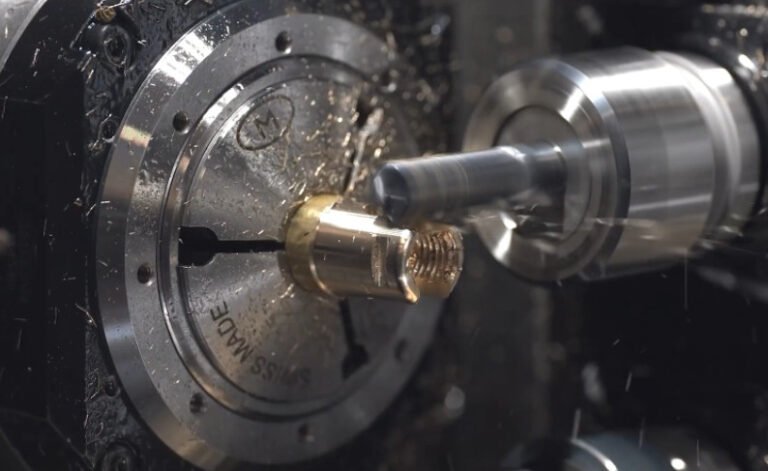

Electrical Discharge Machining, commonly referred to as EDM, is a non-traditional machining process that uses electrical discharges or sparks to erode material from a workpiece. This method is particularly effective for materials with high hardness, such as titanium, hardened steel, and carbide, or for creating intricate shapes that are challenging for conventional machining tools. EDM operates on the principle of controlled erosion, where an electrode and the workpiece are submerged in a dielectric fluid, and a series of electrical discharges remove material with extreme precision.

There are two primary types of EDM processes widely used by electrical discharge machining manufacturers: Wire EDM and Sinker EDM. Wire EDM uses a thin wire as an electrode to cut through materials, ideal for creating complex 2D shapes. Sinker EDM, also known as Die-Sinking EDM, uses a custom-shaped electrode to create cavities or detailed impressions in the workpiece. Both methods offer unparalleled accuracy, often achieving tolerances as tight as ±0.0001 inches (±0.00254 mm).

Key Capabilities of EDM Manufacturers

Electrical discharge machining manufacturers are equipped with advanced technologies and expertise to meet diverse industrial requirements. Their capabilities often extend beyond basic EDM processes, encompassing a range of services and technical proficiencies. Below are some of the core capabilities that define leading EDM manufacturers:

- Precision Machining: EDM manufacturers excel in producing components with tight tolerances, often in the range of ±0.0002 to ±0.0005 inches (±0.005 to ±0.0127 mm), ensuring high accuracy for critical applications.

- Material Versatility: They can work with a wide array of conductive materials, including stainless steel, aluminum, copper, tungsten, and exotic alloys like Inconel and Hastelloy.

- Complex Geometry Handling: EDM is ideal for creating intricate designs, such as narrow slots, deep cavities, and fine holes with diameters as small as 0.004 inches (0.1 mm).

- Custom Tooling and Prototyping: Many manufacturers offer tailored solutions, producing custom electrodes and providing rapid prototyping for unique project needs.

- High-Volume Production: Advanced EDM systems enable manufacturers to handle both small-batch and large-scale production runs efficiently.

These capabilities ensure that EDM manufacturers can address the specific demands of industries requiring high precision and reliability in their components.

Applications of EDM in Various Industries

The versatility of EDM technology makes it indispensable across multiple sectors. Electrical discharge machining manufacturers serve a broad spectrum of industries by delivering components that meet stringent quality and performance standards. Here are some prominent applications:

- Aerospace: EDM is used to produce turbine blades, engine components, and fuel system parts with intricate cooling channels and precise geometries. Tolerances often range from ±0.0001 to ±0.0003 inches (±0.00254 to ±0.00762 mm).

- Automotive: Manufacturers rely on EDM for creating molds, dies, and precision parts like gears and connectors, ensuring durability under high-stress conditions.

- Medical: EDM is critical for producing surgical instruments, implants, and dental tools with complex shapes and biocompatible materials like titanium.

- Tool and Die Making: EDM is widely used for crafting injection molds, stamping dies, and extrusion tools with detailed features and long-lasting performance.

- Electronics: The process aids in manufacturing micro-components, connectors, and circuit board elements with fine details and high conductivity.

These applications highlight the critical role of EDM manufacturers in supporting industries that demand precision-engineered components for safety, efficiency, and innovation.

Technologies Used by EDM Manufacturers

Modern electrical discharge machining manufacturers leverage cutting-edge technologies to enhance their processes and deliver superior results. Their equipment and systems are designed to optimize precision, speed, and efficiency. Some of the key technologies include:

- CNC EDM Machines: Computer Numerical Control (CNC) systems automate the EDM process, allowing for consistent accuracy and repeatability. These machines often feature multi-axis control for complex 3D machining.

- High-Speed EDM: Advanced pulse generators and power supplies enable faster material removal rates (MRR), with some systems achieving speeds up to 0.5 cubic inches per hour (8.2 cm³/hr) for specific materials.

- Micro-EDM: Specialized equipment for micro-machining allows manufacturers to create features as small as 0.002 inches (0.05 mm), catering to industries like electronics and medical devices.

- Automated Electrode Changers: These systems reduce downtime by automatically swapping electrodes during long production runs, improving overall efficiency.

- Dielectric Fluid Systems: Advanced filtration and cooling systems maintain the dielectric fluid's properties, ensuring stable machining conditions and surface finishes as fine as Ra 0.1 µm.

By integrating these technologies, EDM manufacturers can achieve exceptional precision and cater to the evolving needs of their clients with high-quality outputs.

Factors to Consider When Choosing an EDM Manufacturer

Selecting the right electrical discharge machining manufacturer is crucial for ensuring the success of your project. With numerous providers in the market, evaluating their expertise and capabilities is essential. Below are key factors to consider when making your decision:

| Factor | Description |

|---|---|

| Experience and Expertise | Look for manufacturers with a proven track record in EDM, especially in your specific industry. Check their portfolio for similar projects and client testimonials. |

| Equipment and Technology | Ensure the manufacturer uses modern EDM machines and technologies, such as CNC systems and high-speed machining capabilities, to meet your precision and volume requirements. |

| Material Capabilities | Confirm that the manufacturer can handle the specific materials required for your project, especially if working with exotic alloys or hardened metals. |

| Quality Assurance | Check for certifications like ISO 9001, which indicate a commitment to quality control and consistent manufacturing standards. |

| Lead Time and Scalability | Assess their ability to meet deadlines and handle both small prototypes and large production runs without compromising quality. |

By thoroughly evaluating these factors, you can partner with an EDM manufacturer that aligns with your technical requirements and business goals.

Benefits of Partnering with Expert EDM Manufacturers

Collaborating with reputable electrical discharge machining manufacturers offers numerous advantages for businesses seeking high-quality components. These benefits stem from their technical expertise, advanced equipment, and commitment to precision. Some of the key benefits include:

- Unmatched Accuracy: EDM manufacturers deliver components with exceptional precision, often achieving surface finishes as smooth as Ra 0.2 µm and dimensional tolerances within ±0.0001 inches (±0.00254 mm).

- Cost-Effective for Complex Parts: EDM eliminates the need for multiple machining processes, reducing production costs for intricate designs and hard materials.

- Reduced Material Stress: Unlike traditional machining, EDM does not apply mechanical force, minimizing the risk of deformation or stress in delicate components.

- Custom Solutions: Manufacturers provide tailored services, from electrode design to final production, ensuring that unique project specifications are met.

- Reliable Delivery: With streamlined processes and automated systems, leading manufacturers maintain consistent turnaround times, even for high-volume orders.

These advantages make EDM manufacturers invaluable partners for industries requiring precision-engineered solutions with uncompromising quality.

Conclusion

Electrical discharge machining manufacturers play a pivotal role in modern manufacturing, offering specialized solutions for industries that demand precision, durability, and complexity in their components. By leveraging advanced EDM technologies like CNC systems, high-speed machining, and micro-EDM, these manufacturers deliver high-quality results across diverse applications, from aerospace to medical devices. When choosing an EDM partner, businesses must consider factors such as experience, equipment, material capabilities, and quality assurance to ensure a successful collaboration. With the right manufacturer, companies can achieve exceptional accuracy, cost efficiency, and reliable production outcomes, meeting the stringent demands of today's competitive markets.