CNC machining, or Computer Numerical Control machining, is a cornerstone of modern manufacturing, enabling the production of highly precise components across industries like aerospace, automotive, medical, and more. This technology automates the control of machine tools through computer programming, ensuring accuracy, repeatability, and efficiency in creating complex parts. But how does CNC machining work exactly? In this comprehensive guide, we will break down the process, components, and technical aspects of CNC machining in a systematic and detailed manner, providing you with a clear understanding of this critical manufacturing method.

What Is CNC Machining?

CNC machining refers to a subtractive manufacturing process where material is removed from a workpiece using computer-controlled tools to create a desired shape or design. Unlike manual machining, where operators directly control the tools, CNC machining relies on pre-programmed software to dictate the movement of machinery. This results in unparalleled precision, often achieving tolerances as tight as ±0.001 inches (0.0254 mm), depending on the machine and material.

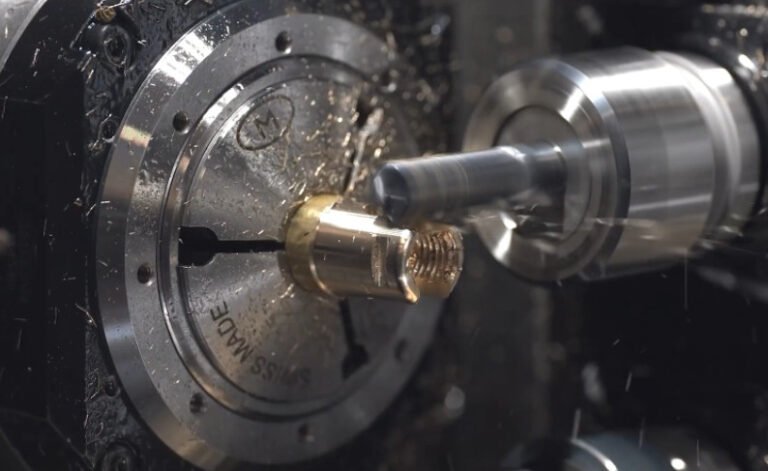

The process is widely used for materials such as metals (aluminum, steel, titanium), plastics, wood, and composites. CNC machines can perform various operations, including milling, turning, drilling, and grinding, making them versatile for producing everything from simple bolts to intricate aerospace components.

The Core Components of a CNC Machine

Understanding how CNC machining works requires familiarity with the key components of a CNC machine. Each part plays a critical role in ensuring the system operates smoothly and delivers precise results. Below are the primary components:

- Control Unit: Often referred to as the "brain" of the CNC machine, the control unit interprets the programmed instructions (G-code) and sends commands to the machine's motors and tools. Modern CNC systems use advanced microprocessors for real-time processing.

- Machine Tool: This is the physical tool that performs the cutting, drilling, or shaping of the material. Examples include end mills, lathes, and drills, which vary based on the type of CNC machine (e.g., milling machine, lathe, router).

- Workholding Device: This secures the workpiece in place during machining. Common devices include vises, clamps, and chucks, ensuring stability to prevent errors caused by movement.

- Drive System: Comprising motors (often servo or stepper motors), ball screws, and linear guides, the drive system controls the precise movement of the machine tool along multiple axes (typically X, Y, and Z).

- Feedback System: Sensors and encoders provide real-time data on the position and speed of the tool, ensuring accuracy by correcting any deviations during operation.

How CNC Machining Works: Step-by-Step Process

The CNC machining process involves several distinct steps, each contributing to the transformation of raw material into a finished product. Below is a detailed breakdown of the workflow:

Step 1: Design and CAD Modeling

The process begins with creating a digital model of the part using Computer-Aided Design (CAD) software. Engineers design the geometry of the component, specifying dimensions, tolerances, and surface finishes. Common CAD software includes SolidWorks, AutoCAD, and Fusion 360. The output is typically a 2D or 3D model saved in formats like STL or STEP.

Step 2: CAM Programming and G-Code Generation

Once the design is complete, Computer-Aided Manufacturing (CAM) software converts the CAD model into machine-readable instructions. CAM tools like Mastercam or Siemens NX generate G-code, a language that dictates the toolpaths, speeds, and feeds for the CNC machine. For example, G01 commands linear movement, while G02 and G03 handle circular interpolation for clockwise and counterclockwise arcs, respectively.

Step 3: Machine Setup

Before machining begins, the operator sets up the CNC machine. This includes loading the raw material (e.g., a block of aluminum with dimensions 100 mm x 100 mm x 50 mm), securing it with a workholding device, and installing the appropriate cutting tools. The machine is also calibrated to ensure the starting position (or "zero point") aligns with the programmed coordinates.

Step 4: Machining Operation

With the setup complete, the CNC machine executes the G-code instructions. The control unit directs the motors to move the tool along the specified axes at precise speeds (e.g., spindle speeds of 5,000 to 20,000 RPM for milling aluminum) and feed rates (e.g., 100 to 500 mm/min). Material is removed layer by layer until the final shape is achieved. Coolants or lubricants may be used to reduce heat and friction, extending tool life.

Step 5: Inspection and Finishing

After machining, the part is inspected using precision tools like calipers, micrometers, or Coordinate Measuring Machines (CMM) to verify dimensions against the design specifications. If necessary, secondary processes such as deburring, polishing, or anodizing are applied to achieve the desired surface finish (e.g., Ra 0.8 µm for smooth surfaces).

Types of CNC Machines and Their Applications

CNC machining encompasses a variety of machine types, each suited for specific tasks. Understanding these machines helps clarify how CNC machining works in different contexts. Below is a table summarizing the most common types:

| Type of CNC Machine | Main Function | Common Applications |

|---|---|---|

| CNC Milling Machine | Cuts and shapes material using rotating tools | Prototypes, engine parts, molds |

| CNC Lathe | Rotates the workpiece for cylindrical shaping | Shafts, bolts, bushings |

| CNC Router | Cuts softer materials like wood or plastic | Furniture, signage, decorative items |

| CNC Plasma Cutter | Uses plasma torch to cut conductive materials | Metal sheets, structural components |

Each machine type operates on the same fundamental principle of computer-controlled precision but varies in tooling and material compatibility. For instance, a CNC milling machine might use a 10 mm diameter end mill at 10,000 RPM to machine a steel block, while a CNC lathe rotates the workpiece at 2,000 RPM for turning operations.

Key Parameters in CNC Machining

The success of CNC machining depends on carefully controlling several parameters to achieve the desired outcome. These parameters are programmed into the G-code or adjusted during setup:

- Spindle Speed: Measured in revolutions per minute (RPM), this determines how fast the cutting tool rotates. For aluminum, speeds often range from 5,000 to 15,000 RPM, while harder materials like stainless steel may require 1,000 to 3,000 RPM to avoid tool wear.

- Feed Rate: This is the speed at which the tool moves through the material, typically in millimeters per minute (mm/min). A common range for milling steel is 50 to 200 mm/min, balancing speed and surface quality.

- Depth of Cut: This refers to how much material is removed in a single pass, often between 0.5 mm and 5 mm per pass, depending on the material and tool strength.

- Tool Material and Geometry: Tools made of carbide or high-speed steel (HSS) are chosen based on the workpiece material. For instance, a carbide end mill with a 4-flute design is ideal for aluminum due to its hardness and chip evacuation properties.

Optimizing these parameters ensures efficient material removal, minimizes tool wear, and achieves the required surface finish and dimensional accuracy.

Advantages of CNC Machining in Manufacturing

CNC machining offers numerous benefits that make it a preferred method in precision manufacturing. These include:

- High Precision: CNC machines can achieve tolerances as tight as ±0.0005 inches (0.0127 mm), critical for industries like aerospace where even minor deviations can lead to failure.

- Repeatability: Once a program is created, the same part can be produced thousands of times with consistent quality, ideal for mass production.

- Complex Geometry: CNC machining can create intricate shapes and internal features that are impossible with manual methods, such as undercuts or compound curves.

- Material Versatility: From soft plastics to hardened steels, CNC machines handle a wide range of materials with appropriate tooling and settings.

Conclusion

CNC machining is a transformative technology that has revolutionized manufacturing by combining computer precision with mechanical prowess. By understanding how CNC machining works—from the initial CAD design to the final inspection—you can appreciate the intricate interplay of software, hardware, and operator expertise that drives this process. Whether it’s milling a complex aerospace component or turning a simple shaft, CNC machining delivers accuracy, efficiency, and versatility. This guide has provided a detailed, technical overview of the process, components, and parameters, equipping you with the knowledge to explore or apply CNC machining in various industrial contexts.