Oxidizing aluminum creates a protective oxide layer that enhances corrosion resistance, durability, and aesthetic appeal. This process, often achieved through natural oxidation or controlled methods like anodizing, is widely used in industries such as aerospace, automotive, and construction. Below, we explore the science, methods, and technical parameters for oxidizing aluminum effectively, providing a systematic guide for professionals and enthusiasts.

Understanding Aluminum Oxidation

Aluminum naturally forms a thin oxide layer (Al₂O₃) when exposed to oxygen. This layer, typically 2-3 nanometers thick, provides some corrosion resistance but is insufficient for demanding applications. Controlled oxidation, such as anodizing, thickens this layer to 5-25 micrometers or more, improving hardness, wear resistance, and adhesion for coatings. The oxide layer’s properties depend on the oxidation method, alloy composition, and process parameters.

Oxidation involves the reaction of aluminum with oxygen, often facilitated by electrochemical processes. The resulting aluminum oxide is chemically stable, non-conductive, and tightly adheres to the metal surface. Key factors influencing the oxide layer include temperature, electrolyte composition, and current density.

Natural Oxidation of Aluminum

Natural oxidation occurs when aluminum is exposed to air. The process is slow and self-limiting, as the oxide layer inhibits further oxygen diffusion. While this provides basic protection, it is inadequate for harsh environments like marine or industrial settings. The layer’s thickness and uniformity depend on environmental factors such as humidity and temperature.

To enhance natural oxidation, aluminum surfaces can be cleaned and exposed to controlled humid environments. However, this method is rarely used industrially due to its inconsistency and limited control over layer thickness.

Anodizing: Electrochemical Oxidation

Anodizing is the most common method for oxidizing aluminum, producing a thick, uniform oxide layer through an electrochemical process. The aluminum acts as the anode in an electrolyte bath, typically sulfuric acid, with a cathode completing the circuit. Oxygen ions bond with the aluminum surface, forming a porous oxide layer that can be sealed for added protection.

Anodizing is categorized into three types based on electrolyte and parameters:

| Type | Electrolyte | Thickness (µm) | Applications |

|---|---|---|---|

| Type I (Chromic Acid) | Chromic acid | 0.5-7.6 | Aerospace, corrosion resistance |

| Type II (Sulfuric Acid) | Sulfuric acid | 1.8-25 | Architectural, consumer goods |

| Type III (Hard Anodizing) | Sulfuric acid (low temp) | 25-150 | Industrial, wear-resistant parts |

Each type suits specific applications based on the required oxide thickness and properties.

Key Parameters in Anodizing

Anodizing’s success depends on precise control of process parameters. Below are the critical factors and their typical ranges:

- Electrolyte Concentration: For sulfuric acid anodizing, 10-20% (w/v) is common. Higher concentrations increase conductivity but may reduce layer quality.

- Temperature: Typically 15-25°C for Type II anodizing; 0-5°C for Type III. Lower temperatures produce denser, harder coatings.

- Current Density: Ranges from 1-3 A/dm² for Type II and 2-4 A/dm² for Type III. Higher densities accelerates oxidation but risks burning.

- Voltage: 12-18 V for Type II; up to 75 V for Type III. Voltage affects pore size and layer thickness.

- Time: 20-60 minutes for Type II; 60-120 minutes for Type III, depending on desired thickness.

These parameters must be optimized based on the aluminum alloy, as impurities like copper or silicon can affect oxide formation.

Surface Preparation for Oxidation

Proper surface preparation ensures a uniform oxide layer. The process involves several steps:

- Degreasing: Remove oils and contaminants using alkaline cleaners (pH 9-11) at 50-70°C for 5-10 minutes.

- Etching: Smooth the surface with sodium hydroxide (5-10% w/v) at 40-60°C for 1-5 minutes to remove imperfections.

- Desmutting: Eliminate residual alloys or oxides using nitric acid (20-30% v/v) at room temperature for 1-2 minutes.

- Rinsing: Use deionized water to prevent contamination between steps.

Inadequate preparation can lead to uneven oxidation or poor adhesion of the oxide layer.

Sealing the Oxide Layer

After anodizing, the oxide layer is porous and must be sealed to enhance corrosion resistance and durability. Sealing methods include:

- Hot Water Sealing: Immerse in deionized water at 95-100°C for 10-30 minutes. This hydrates the oxide, closing pores.

- Nickel Acetate Sealing: Use a 5-10 g/L nickel acetate solution at 80-90°C for 5-15 minutes. This improves corrosion resistance in alkaline environments.

- Cold Sealing: Apply a fluoride-based solution at 25-35°C for 5-10 minutes, suitable for decorative finishes.

Sealing quality is tested using dye penetration or impedance measurements to ensure pore closure.

Other Oxidation Methods

Besides anodizing, alternative methods exist for oxidizing aluminum, though they are less common:

- Chemical Oxidation: Immersion in alkaline or acidic solutions, like sodium carbonate (5-10% w/v) at 60-80°C, forms a thin oxide layer (0.1-1 µm). Used for decorative or low-durability applications.

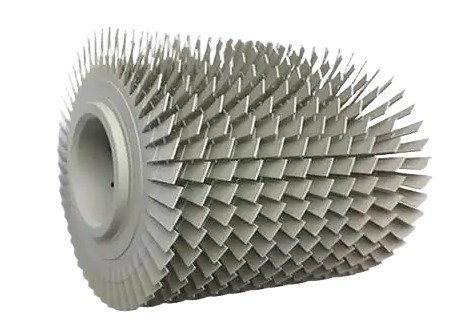

- Plasma Electrolytic Oxidation (PEO): Uses high-voltage plasma discharges in an alkaline electrolyte to form a ceramic-like oxide layer (50-200 µm). Suitable for high-wear applications but requires specialized equipment.

- Thermal Oxidation: Heating aluminum to 300-500°C in an oxygen-rich environment forms a thin oxide layer (0.01-0.1 µm). Limited to specific alloys due to thermal stress risks.

These methods are selected based on cost, equipment availability, and application requirements.

Testing and Quality Control

Ensuring the oxide layer meets specifications requires rigorous testing. Common methods include:

| Test | Parameter | Standard |

|---|---|---|

| Thickness Measurement | Eddy current or microscopy | ASTM B244 |

| Hardness | Microhardness (Vickers) | 500-1500 HV for Type III |

| Corrosion Resistance | Salt spray test | ASTM B117 (>1000 hours) |

Regular calibration of equipment and adherence to standards ensure consistent results.

Applications of Oxidized Aluminum

Oxidized aluminum is used across industries due to its enhanced properties:

- Aerospace: Anodized components like fuselage panels resist corrosion and wear.

- Automotive: Hard-anodized pistons and gears improve durability.

- Architecture: Type II anodized panels provide aesthetic and weather-resistant finishes.

- Electronics: Oxide layers insulate and protect circuit board components.

The choice of oxidation method depends on the application’s environmental and mechanical demands.

Environmental and Safety Considerations

Oxidation processes, particularly anodizing, involve hazardous chemicals like sulfuric acid and chromic acid. Proper ventilation, personal protective equipment (PPE), and waste treatment are essential. Regulations like REACH and OSHA govern chemical handling and disposal. Using chromic acid alternatives, such as boric-sulfuric acid anodizing, reduces environmental impact.

Conclusion

Oxidizing aluminum enhances its durability, corrosion resistance, and functionality across various applications. Anodizing remains the most effective method, with precise control over parameters ensuring high-quality results. By understanding the science, methods, and testing protocols, professionals can achieve consistent, reliable oxide layers tailored to specific needs.

FAQs About Aluminum Oxidation

What is aluminum oxidation?

Aluminum oxidation is the process by which aluminum reacts with oxygen to form a protective aluminum oxide (Al₂O₃) layer on its surface. This layer enhances corrosion resistance, durability, and wear resistance, making aluminum suitable for demanding applications in aerospace, automotive, and construction. While natural oxidation creates a thin (2-3 nm) layer, controlled methods like anodizing produce thicker (5-150 µm) layers for superior performance.

How does natural oxidation differ from controlled oxidation methods like anodizing?

Natural oxidation occurs spontaneously when aluminum is exposed to air, forming a thin, self-limiting oxide layer. It provides basic protection but is inconsistent and insufficient for harsh environments. Controlled methods, such as anodizing, use electrochemical processes to deliberately thicken and uniformize the oxide layer. Anodizing offers precise control over thickness, hardness, and porosity, making it suitable for industrial applications.

Are there alternative oxidation methods besides anodizing?

Yes, though less common:

Chemical Oxidation: Uses alkaline/acidic solutions (e.g., sodium carbonate) to form thin (0.1-1 µm) layers for decorative purposes.

Plasma Electrolytic Oxidation (PEO): Uses high-voltage plasma to create thick (50-200 µm) ceramic-like layers for high-wear applications.

Thermal Oxidation: Heats aluminum in oxygen-rich environments to form thin (0.01-0.1 µm) layers, limited to specific alloys.