Low volume production refers to manufacturing processes designed to produce small quantities of parts or products, typically ranging from a few units to several thousand. Unlike high volume production, which focuses on economies of scale, low volume production prioritizes flexibility, customization, and cost-efficiency for smaller batches. This approach is widely used in industries such as aerospace, medical devices, automotive, and consumer electronics, where specialized or custom products are needed. This article explores the types of low volume production, their key parameters, and their applications, providing a technical and systematic overview.

Types of Low Volume Production

Low volume production encompasses several manufacturing methods, each suited to specific needs based on part complexity, material requirements, and production goals. The primary types include prototyping, batch production, and on-demand manufacturing. Each method has distinct characteristics, making them suitable for different applications.

Prototyping

Prototyping involves producing a limited number of parts to test designs, validate functionality, or demonstrate concepts before full-scale production. It is commonly used in product development to refine designs and ensure performance meets specifications. Prototyping allows manufacturers to identify design flaws, assess material suitability, and gather feedback without committing to large-scale production.

Prototyping methods include 3D printing (additive manufacturing), CNC machining, and injection molding with soft tooling. For example, 3D printing is ideal for creating complex geometries with minimal setup time, while CNC machining offers high precision for metal or plastic prototypes. The choice of method depends on the part's material, tolerances, and intended use.

| Prototyping Method | Materials | Tolerance (mm) | Typical Lead Time | Applications |

|---|---|---|---|---|

| 3D Printing | Plastics, resins, metals | ±0.1 to ±0.5 | 1-5 days | Functional prototypes, concept models |

| CNC Machining | Metals, plastics | ±0.01 to ±0.05 | 3-10 days | High-precision components, test parts |

| Injection Molding (Soft Tooling) | Thermoplastics | ±0.05 to ±0.2 | 2-4 weeks | Pre-production parts, small batches |

Batch Production

Batch production involves manufacturing a specific quantity of parts in a single production run, typically ranging from 50 to 10,000 units. This method balances flexibility and cost-efficiency, making it suitable for products with moderate demand or seasonal variations. Batch production is common in industries like automotive, where small runs of specialty parts are needed, or in consumer goods for limited-edition products.

Key processes in batch production include CNC machining, injection molding, and sheet metal fabrication. Injection molding, for instance, uses hard tooling for higher volumes within the low volume range, offering repeatability and cost savings over prototyping. Batch production requires careful planning to optimize setup times and material usage, ensuring cost-effectiveness.

Parameters for batch production include production volume, cycle time, and tooling costs. For example, injection molding for 1,000 units may have a cycle time of 30-60 seconds per part, with tooling costs ranging from $5,000 to $20,000 depending on mold complexity. These parameters influence the overall cost and feasibility of batch production.

On-Demand Manufacturing

On-demand manufacturing produces parts as needed, often in response to customer orders, minimizing inventory and waste. This method is ideal for custom products, spare parts, or niche markets where demand is unpredictable. On-demand manufacturing leverages technologies like 3D printing and CNC machining, allowing rapid production without long lead times.

This approach is common in industries like medical devices, where custom implants are produced for individual patients, or in aerospace for replacement parts. On-demand manufacturing requires robust digital systems for order processing and production scheduling to ensure timely delivery. Parameters such as part complexity, material availability, and production speed are critical to its success.

Key Parameters in Low Volume Production

Low volume production is defined by several technical parameters that influence process selection, cost, and quality. Understanding these parameters ensures manufacturers choose the most suitable method for their needs. The following sections detail the most critical parameters: material selection, tolerances, lead time, and cost considerations.

Material Selection

Material choice is a cornerstone of low volume production, as it affects part performance, cost, and manufacturing feasibility. Common materials include plastics (e.g., ABS, polycarbonate), metals (e.g., aluminum, stainless steel), and composites. Each material has specific properties, such as tensile strength or thermal resistance, that dictate its suitability for a given application.

For example, ABS plastic is widely used in 3D printing and injection molding due to its durability and low cost, with a tensile strength of approximately 40 MPa. In contrast, aluminum, used in CNC machining, offers higher strength (200-400 MPa) and is preferred for aerospace components. Material availability can also impact lead times, especially for specialty alloys or composites.

Tolerances

Tolerances refer to the allowable deviation in part dimensions, critical for ensuring components meet design specifications. Low volume production often requires tight tolerances, especially for industries like medical devices or aerospace, where precision is non-negotiable. For instance, CNC machining can achieve tolerances as low as ±0.01 mm, while 3D printing typically ranges from ±0.1 to ±0.5 mm.

Tolerance requirements influence process selection. High-precision parts may necessitate CNC machining or laser cutting, while less critical components can use additive manufacturing. Manufacturers must balance tolerance needs with cost, as tighter tolerances increase machining time and complexity.

Lead Time

Lead time is the duration from order placement to part delivery, a critical factor in low volume production. Prototyping methods like 3D printing offer lead times of 1-5 days, while injection molding with hard tooling may take 4-8 weeks due to mold fabrication. On-demand manufacturing prioritizes short lead times, often leveraging digital workflows to expedite production.

Lead time is influenced by factors such as part complexity, material availability, and production capacity. For example, a complex CNC-machined part may require multiple setups, extending lead time to 10-14 days. Efficient production planning and supplier coordination are essential to minimize delays.

Cost Considerations

Cost is a key parameter in low volume production, driven by tooling, material, and labor expenses. Prototyping typically has lower tooling costs (e.g., $500-$2,000 for 3D printing) but higher per-part costs due to limited economies of scale. Batch production reduces per-part costs through higher volumes but requires significant upfront tooling investment, such as $10,000-$50,000 for injection molds.

On-demand manufacturing balances cost and flexibility by eliminating inventory expenses. For example, producing 100 custom parts via 3D printing may cost $50-$100 per part, while injection molding the same quantity could reduce costs to $5-$10 per part, excluding tooling. Cost optimization requires analyzing production volume, material costs, and process efficiency.

| Production Type | Tooling Cost | Per-Part Cost | Typical Volume | Lead Time |

|---|---|---|---|---|

| Prototyping | $500-$5,000 | $20-$200 | 1-100 units | 1-14 days |

| Batch Production | $5,000-$50,000 | $5-$50 | 50-10,000 units | 2-8 weeks |

| On-Demand Manufacturing | $0-$5,000 | $10-$100 | 1-1,000 units | 1-10 days |

Applications of Low Volume Production

Low volume production serves diverse industries, enabling the creation of specialized, high-quality parts without the need for mass production. Below are key applications, highlighting how each production type aligns with industry needs.

Aerospace

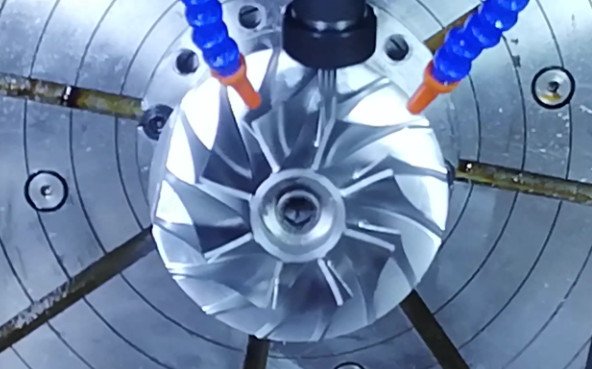

In aerospace, low volume production is used for prototypes, spare parts, and custom components. For example, CNC machining produces high-precision brackets with tolerances of ±0.01 mm, while 3D printing creates lightweight composite structures. Batch production is used for limited runs of specialty parts, such as turbine blades, with volumes of 100-1,000 units.

Medical Devices

The medical device industry relies on low volume production for custom implants, surgical tools, and prototypes. On-demand manufacturing is critical for patient-specific implants, such as titanium spinal cages produced via 3D printing. Tight tolerances (±0.05 mm) and biocompatible materials like PEEK are essential to meet regulatory standards.

Automotive

Automotive applications include prototyping for new vehicle designs and batch production for aftermarket or specialty parts. For instance, injection molding produces small batches of dashboard components, while CNC machining creates precision engine parts. On-demand manufacturing supports spare parts production, reducing inventory costs.

Consumer Electronics

Low volume production in consumer electronics focuses on prototypes and limited-edition products. 3D printing is used for rapid prototyping of device casings, while batch production creates small runs of high-end accessories, such as custom earbuds with injection-molded housings. Lead times of 1-10 days are critical to meet market demands.

Choosing the Right Low Volume Production Method

Selecting the appropriate low volume production method depends on several factors, including part complexity, material requirements, volume, and budget. Prototyping is ideal for early-stage design validation, offering quick turnaround and flexibility. Batch production suits moderate volumes with repeatable quality, while on-demand manufacturing excels for custom or urgent orders.

Manufacturers must evaluate parameters like tolerances, lead times, and costs to align with project goals. For example, a medical device company needing 50 custom implants may choose 3D printing for its speed and customization, while an automotive supplier producing 5,000 parts may opt for injection molding to reduce per-part costs.

Collaboration with experienced manufacturing partners can streamline decision-making. Suppliers with expertise in multiple processes can recommend the best approach based on technical requirements and production constraints, ensuring optimal outcomes.

Conclusion

Low volume production offers a versatile solution for manufacturing small quantities of parts with high precision and customization. By understanding the types—prototyping, batch production, and on-demand manufacturing—and their key parameters, such as material selection, tolerances, lead times, and costs, manufacturers can make informed decisions to meet specific needs. Applications in aerospace, medical devices, automotive, and consumer electronics demonstrate the versatility of these methods. A systematic approach to selecting the right process ensures efficiency, quality, and cost-effectiveness in low volume production.