Micro Arc Oxidation (MAO), also known as Plasma Electrolytic Oxidation (PEO), is an advanced electrochemical surface treatment technology that forms thick, dense, and adherent ceramic oxide coatings on lightweight metals such as aluminum, magnesium, titanium, and their alloys. This guide provides a detailed, technical, and systematic overview of MAO, covering its principles, process parameters, coating properties, applications, advantages, and limitations, tailored for engineers, researchers, and industry professionals seeking a comprehensive understanding of this process.

Overview of Micro Arc Oxidation

MAO is a plasma-chemical and electrochemical process that combines high-voltage electrical discharges (micro arcs) with electrochemical oxidation in an alkaline electrolyte bath. Unlike conventional anodizing, which operates at lower voltages (10–100 V), MAO employs voltages of 200–800 V to generate localized plasma discharges. These discharges trigger complex electrochemical and plasma-chemical reactions, resulting in crystalline ceramic coatings with superior hardness, wear resistance, corrosion resistance, and adhesion compared to traditional anodized layers. The process is particularly suited for valve metals (e.g., aluminum, titanium, magnesium, zirconium, and niobium) and their alloys, producing coatings that enhance surface performance in demanding environments.

MAO coatings are widely applied in industries such as aerospace, automotive, biomedical, electronics, and consumer goods due to their ability to improve the durability, functionality, and longevity of metal components. The coatings grow both inward and outward from the substrate, ensuring strong adhesion and resistance to peeling or flaking.

Working Principles of Micro Arc Oxidation

The MAO process occurs in an aqueous electrolyte solution, typically containing silicates, phosphates, or aluminates, where the metal workpiece acts as the anode and a stainless-steel container or electrode serves as the cathode. The mechanism can be broken down into four key stages:

- Initial Oxidation: At low voltages (below 100 V), a thin oxide film forms on the metal surface through electrochemical oxidation, similar to conventional anodizing. This film is typically amorphous and serves as the foundation for subsequent growth.

- Dielectric Breakdown and Micro Arcs: As the applied voltage increases beyond the dielectric strength of the oxide film (typically >200 V), localized breakdowns occur. These breakdowns generate short-lived micro arcs with extremely high temperatures (up to 10,000°C) and pressures at the metal-oxide-electrolyte interface. The arcs are confined to small areas (0.1–1 mm²) and last for microseconds.

- Oxide Growth: The intense heat from micro arcs melts the underlying metal and oxidizes it, while the surrounding electrolyte rapidly quenches and solidifies the molten oxide. This results in a porous yet dense ceramic layer, often containing crystalline phases such as corundum (α-Al2O3) for aluminum, rutile/anatase (TiO2) for titanium, or periclase (MgO) for magnesium.

- Coating Thickening: The process is iterative, with new oxide layers forming and sintering onto the existing coating. Coating thickness typically ranges from 5–100 µm but can exceed 200 µm with extended processing times or optimized parameters.

The incorporation of electrolyte constituents (e.g., silicon, calcium, or phosphorus) into the coating during plasma discharges enhances its functionality, such as improving corrosion resistance or bioactivity for specific applications.

Key Process Parameters

The properties of MAO coatings are highly dependent on several process parameters, which must be precisely controlled to achieve desired outcomes. The table below summarizes these parameters, their typical ranges, and their impact on the coating:

| Parameter | Typical Range | Impact on Coating |

|---|---|---|

| Voltage | 200–600 V (DC or pulsed DC) | Higher voltages increase arc intensity, coating thickness, and porosity but may cause cracks. |

| Current Density | 1–50 A/dm² | Higher densities accelerates oxide growth but may increase surface roughness. |

| Frequency | 50–1000 Hz | Lower frequencies reduce porosity; higher frequencies enhance compactness. |

| Duty Ratio | 10–60% | Higher ratios improve coating density but may increase roughness. |

| Electrolyte Composition | KOH, Na2SiO3, NaH2PO4, NaAlO2 | Influences chemical composition (e.g., Si for corrosion resistance, Ca/P for bioactivity). |

| Treatment Time | 10–60 minutes | Longer times increase thickness but may degrade quality if excessive. |

| Electrolyte Temperature | 20–60°C | Higher temperatures may destabilize the electrolyte; cooling maintains stability. |

These parameters are interdependent. For example, increasing voltage and treatment time can produce thicker coatings but may lead to larger pores or microcracks, which could compromise corrosion resistance. Electrolyte composition plays a critical role in determining the coating’s chemical and functional properties, such as incorporating silica for corrosion resistance or calcium/phosphorus for biocompatibility.

Equipment and Setup

The MAO process requires specialized equipment to handle high voltages and maintain process stability. Key components include:

- Power Supply: A high-voltage power supply delivering pulsed DC or AC, typically 0–800 V, with current capacities of 5–500 A. Pulsed power supplies are preferred for better control over arc formation.

- Electrolytic Cell: A stainless-steel or polymer-lined container holding the aqueous electrolyte, equipped with a cooling system to maintain temperatures between 20–60°C.

- Electrodes: The workpiece serves as the anode, while a stainless-steel plate or the cell wall acts as the cathode.

- Cooling and Stirring Systems: To regulate electrolyte temperature and ensure uniform ion distribution, preventing localized overheating or depletion.

- Control System: A programmable controller or pulse rectifier to adjust voltage, current, frequency, and duty ratio in real time.

Regular maintenance of the electrolyte (e.g., monitoring pH and concentration) and cleaning of the cell are essential to ensure consistent coating quality and prevent contamination.

Properties of MAO Coatings

MAO coatings exhibit a unique combination of properties that make them superior to coatings produced by conventional anodizing or electroplating:

- Thickness: Ranges from 5–100 µm, with some applications achieving up to 200 µm.

- Hardness: Typically 300–2000 HV, depending on the substrate and electrolyte. Aluminum-based coatings often reach 1200–2000 HV due to the formation of α-Al2O3.

- Wear Resistance: Excellent due to high hardness and dense microstructure, outperforming hard-anodized coatings by 2–5 times.

- Corrosion Resistance: Superior to anodizing, as the thick, chemically stable oxide layer acts as a barrier against moisture, salt, and other corrosive agents. Incorporation of elements like silicon or phosphorus further enhances protection.

- Adhesion: Strong chemical and mechanical bonding to the substrate, reducing the risk of peeling or flaking, as the coating grows both inward and outward.

- Thermal Resistance: Can withstand temperatures up to 800°C for aluminum alloys and higher for titanium, making them suitable for high-temperature environments.

- Porosity: Controlled porosity (5–30%) allows for post-treatment impregnation with lubricants, polymers, or bioactive compounds to tailor properties.

- Dielectric Properties: High electrical insulation (breakdown voltages of 500–2000 V), ideal for electronic applications.

The phase composition of MAO coatings varies by substrate, typically including crystalline phases like α-Al2O3 (corundum), TiO2 (rutile/anatase), or MgO, which contribute to their hardness and stability.

Applications of Micro Arc Oxidation

MAO coatings are employed across a wide range of industries due to their versatility and performance. Key applications include:

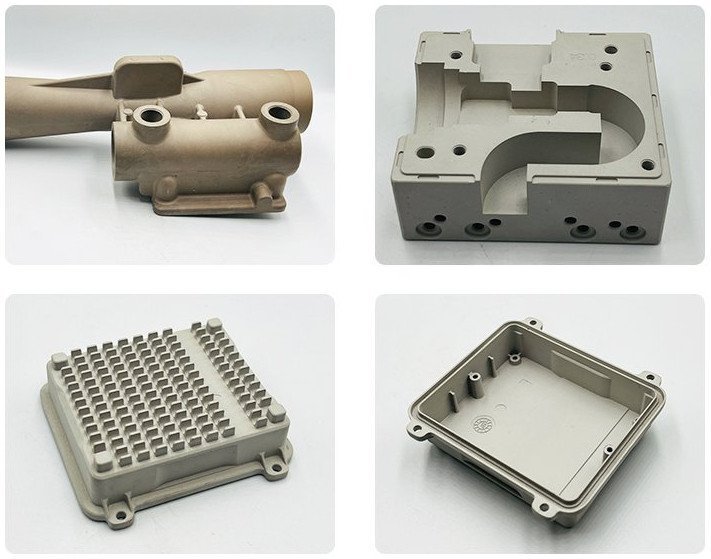

- Aerospace: Aluminum and magnesium alloy components, such as fasteners, engine parts, and structural elements, benefit from MAO’s corrosion and wear resistance, reducing maintenance and extending service life.

- Automotive: Titanium and magnesium alloy parts, including piston rods, cylinder liners, and chassis components, use MAO coatings for durability and weight reduction, improving fuel efficiency.

- Biomedical: Titanium implants, such as bone screws, dental implants, and hip replacements, leverage MAO coatings with calcium and phosphorus incorporation to enhance biocompatibility and osseointegration.

- Electronics: Insulating coatings on magnesium alloy casings for smartphones, laptops, and tablets, or on aluminum heat sinks, provide scratch resistance, corrosion protection, and dielectric properties.

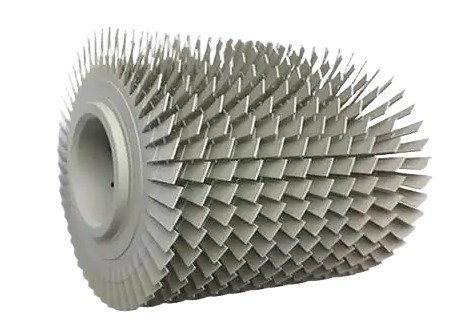

- Industrial Machinery: Aluminum and magnesium components, such as textile machinery guide wheels, printing rollers, and pump housings, use MAO coatings for wear and corrosion resistance.

- Consumer Goods: Sports equipment (e.g., bicycle frames, golf clubs) and tools benefit from MAO’s lightweight, scratch-resistant, and corrosion-resistant properties.

Advantages of Micro Arc Oxidation

MAO offers significant advantages over traditional surface treatment methods like anodizing, electroplating, or thermal spraying:

- Superior Properties: Coatings are 2–5 times harder and more wear-resistant than hard-anodized layers, with better corrosion resistance and adhesion.

- Environmental Friendliness: Uses dilute, non-toxic electrolytes (e.g., KOH, Na2SiO3) without heavy metals or strong acids, unlike chromate-based treatments.

- Versatility: Applicable to multiple lightweight metals (Al, Mg, Ti, Zr, Nb) with customizable properties through electrolyte and parameter adjustments.

- Durability: Extends component lifespan by 5–10 times in harsh environments, reducing replacement costs.

- Functional Tailoring: Controlled porosity and electrolyte incorporation enable specialized coatings (e.g., bioactive, self-lubricating, or insulating).

Limitations of Micro Arc Oxidation

Despite its advantages, MAO has certain limitations that must be considered during implementation:

- High Energy Consumption: Requires high voltages (200–600 V) and current densities (1–50 A/dm²), leading to higher operational costs compared to conventional anodizing.

- Surface Imperfections: Micro-pores (0.15–15 µm) and occasional microcracks may form, potentially reducing corrosion resistance unless sealed or post-treated.

- Substrate Sensitivity: Coating quality depends on alloy composition; high silicon or copper content in aluminum alloys may degrade performance.

- Equipment Complexity: Specialized high-voltage power supplies, cooling systems, and control units increase capital costs and require skilled operation.

- Limited Substrate Range: Primarily applicable to conductive valve metals (Al, Mg, Ti, Zr, Nb), excluding non-conductive or non-valve materials.

- Surface Roughness: MAO coatings may increase surface roughness (Ra 1–10 µm), requiring post-polishing for aesthetic or precision applications.

These limitations can often be mitigated through parameter optimization, electrolyte selection, or post-treatments like sealing or polishing.

Comparison with Conventional Anodizing

The table below compares MAO with conventional anodizing to highlight their differences:

| Feature | Micro Arc Oxidation | Conventional Anodizing |

|---|---|---|

| Voltage | 200–600 V | 10–100 V |

| Coating Thickness | 5–100 µm (up to 200 µm) | 5–50 µm |

| Hardness | 300–2000 HV | 300–500 HV |

| Phase Structure | Crystalline (e.g., α-Al2O3, TiO2) | Amorphous |

| Corrosion Resistance | Superior (dense, thick layer) | Moderate |

| Wear Resistance | Excellent | Moderate |

| Applicable Metals | Al, Mg, Ti, Zr, Nb | Primarily Al |

| Environmental Impact | Low (non-toxic electrolytes) | Moderate (acidic electrolytes) |

Practical Implementation Tips

To achieve high-quality MAO coatings, consider the following practical recommendations:

- Surface Preparation: Clean substrates using ultrasonic cleaning with deionized water and ethanol to remove oils, oxides, or contaminants, ensuring uniform coating growth.

- Electrolyte Optimization: Tailor electrolyte composition to the application (e.g., Na2SiO3 for corrosion resistance, NaH2PO4 for bioactivity) and monitor pH and concentration regularly.

- Parameter Control: Start with lower voltages (200–300 V) and frequencies (50–200 Hz) to minimize defects, then adjust based on thickness and quality requirements.

- Post-Treatment: Apply sealing with polymers or lubricants to fill micro-pores, enhancing corrosion resistance or reducing friction. Polishing may be needed for aesthetic applications.

- Quality Assurance: Use scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy-dispersive spectroscopy (EDS) to analyze coating morphology, phase composition, and elemental distribution.

- Process Monitoring: Continuously monitor electrolyte temperature (20–60°C) and arc behavior to prevent overheating or unstable discharges.

Conclusion

Micro Arc Oxidation is a transformative surface treatment technology that produces high-performance ceramic coatings on lightweight metals like aluminum, magnesium, and titanium. By leveraging high-voltage plasma discharges, MAO creates coatings with exceptional hardness, wear resistance, corrosion resistance, and adhesion, surpassing the capabilities of conventional anodizing. Its versatility, environmental friendliness, and ability to tailor coating properties make it a critical process in industries such as aerospace, automotive, biomedical, electronics, and consumer goods. While limitations like high energy consumption and surface roughness exist, these can be addressed through careful parameter optimization, electrolyte design, and post-treatments. This technical guide provides a comprehensive foundation for understanding and implementing MAO, enabling professionals to maximize its potential for enhancing metal surface performance.