3D metal printing, a key segment of additive manufacturing, constructs metal parts layer by layer from digital models, enabling complex geometries for industries such as aerospace, automotive, medical, and tooling. This article provides a detailed overview of eleven 3D metal printing technologies: Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), Binder Jetting, Directed Energy Deposition (DED), Laser Engineered Net Shaping (LENS), Selective Laser Sintering (SLS) for Metals, Metal Fused Filament Fabrication (Metal FFF), Electron Beam Freeform Fabrication (EBF3), Plasma Arc Welding-based 3D Printing, and Ultrasonic Additive Manufacturing (UAM). Each technology is described with process details, key parameters, materials, and applications.

Selective Laser Melting (SLM)

SLM is a powder bed fusion process that fully melts metal powder using a high-power laser, creating dense, homogenous parts in an inert gas-filled chamber, typically argon, to prevent oxidation.

Process and Parameters

A laser scans a thin layer of metal powder (20-100 µm) on a build platform, melting particles based on a 3D model. The platform lowers, and a recoater applies a new layer. Key parameters include:

- Laser Power: 400-1000 W, ensuring complete melting.

- Scan Speed: 800-2000 mm/s, balancing density and speed.

- Layer Thickness: 20-100 µm, affecting resolution and build time.

- Hatch Spacing: 0.08-0.15 mm, ensuring uniform fusion.

- Powder Particle Size: 20-63 µm, supporting high-density parts.

SLM achieves near-full density (99.5-99.9%), with tensile strengths comparable to forged materials. Surface roughness (Ra 8-15 µm) often requires post-processing like polishing.

Materials and Applications

Materials include titanium (Ti6Al4V), stainless steel (316L), cobalt-chrome, and nickel alloys (Inconel 718). SLM is used in aerospace for turbine blades, medical for implants, and tooling for high-precision molds.

Direct Metal Laser Sintering (DMLS)

DMLS, a powder bed fusion technology, uses a laser to sinter metal powder, bonding particles without full melting, suitable for complex, high-strength parts.

Process and Parameters

A recoater spreads a powder layer (20-50 µm), and a laser sinters particles in an inert atmosphere. Parameters include:

- Laser Power: 200-400 W, optimized for sintering.

- Scan Speed: 500-1500 mm/s, balancing precision and speed.

- Layer Thickness: 20-50 µm, determining resolution.

- Hatch Spacing: 0.1-0.2 mm, affecting strength.

- Powder Particle Size: 15-45 µm, ensuring uniform bonding.

DMLS parts achieve >99% density, with surface roughness (Ra 10-20 µm) often requiring machining or heat treatment.

Materials and Applications

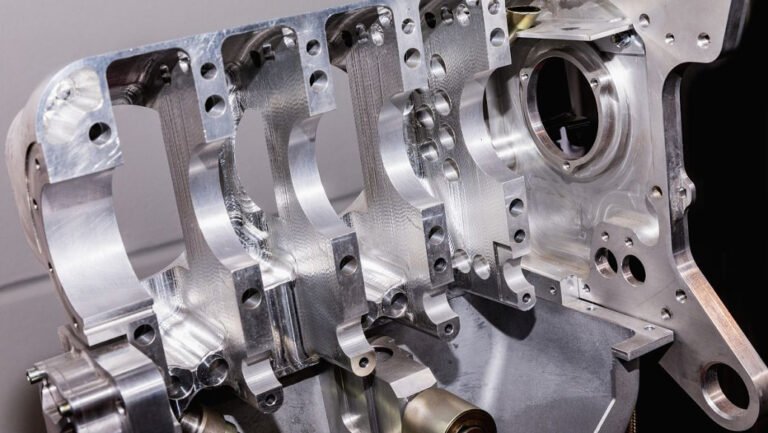

Materials include stainless steel, titanium, aluminum (AlSi10Mg), and Inconel. DMLS is used in aerospace for brackets, medical for custom implants, and automotive for engine components.

Electron Beam Melting (EBM)

EBM uses an electron beam to melt metal powder in a vacuum, ideal for high-temperature alloys and conductive materials, with reduced residual stresses due to high chamber temperatures.

Process and Parameters

An electron beam (50-60 kV) scans a powder bed (50-200 µm) in a preheated vacuum chamber (600-1000°C). Parameters include:

- Beam Power: 3-6 kW, enabling rapid melting.

- Scan Speed: 1000-8000 mm/s, faster than laser methods.

- Layer Thickness: 50-200 µm, coarser than SLM.

- Powder Particle Size: 45-100 µm, suited for high energy.

- Chamber Temperature: 600-1000°C, minimizing stress.

EBM parts have 98-99% density, with rougher surfaces (Ra 20-35 µm) requiring machining.

Materials and Applications

EBM is limited to conductive materials like titanium and cobalt-chrome, used in medical for orthopedic implants and aerospace for turbine parts.

Binder Jetting

Binder Jetting deposits a liquid binder onto metal powder to form a green part, which is debound and sintered in a furnace, enabling high-volume production without supports.

Process and Parameters

A printhead jets binder onto a powder bed (50-100 µm), followed by debinding and sintering (1200-1400°C). Parameters include:

- Layer Thickness: 50-100 µm, balancing speed and resolution.

- Binder Saturation: 60-100%, affecting green part strength.

- Sintering Temperature: 1200-1400°C, material-dependent.

- Powder Particle Size: 20-50 µm, ensuring uniform binding.

- Print Speed: 10-20 mm/h in Z-direction, faster than fusion methods.

Parts achieve 95-98% density with 15-20% shrinkage. Surface finish (Ra 6-12 µm) may require polishing.

Materials and Applications

Materials include stainless steel, copper, and Inconel, used in automotive components, jewelry, and industrial tooling.

Directed Energy Deposition (DED)

DED melts metal powder or wire using a focused energy source (laser, electron beam, or plasma arc), ideal for large parts and repairs.

Process and Parameters

A nozzle deposits material, melted by an energy source, and solidified layer by layer, often using a robotic arm. Parameters include:

- Laser Power: 1-6 kW, depending on deposition rate.

- Deposition Rate: 0.5-5 kg/h, higher for wire.

- Layer Thickness: 0.25-1 mm, coarser than powder bed methods.

- Spot Size: 1-5 mm, affecting resolution.

- Feedstock Type: Powder (20-100 µm) or wire (0.8-3 mm).

DED parts have 98-99% density, with rough surfaces (Ra 20-50 µm) requiring machining.

Materials and Applications

Materials include titanium, stainless steel, and aluminum, used in aerospace for structural parts, repairs, and industrial cladding.

Laser Engineered Net Shaping (LENS)

LENS, a subset of DED, uses a laser to melt metal powder delivered through a nozzle, enabling precise deposition for complex parts and repairs.

Process and Parameters

Powder is injected into a laser focal point, melted, and deposited on a substrate. Parameters include:

- Laser Power: 0.5-4 kW, controlling melt pool size.

- Deposition Rate: 0.5-2 kg/h, slower than other DED methods.

- Layer Thickness: 0.2-0.5 mm, offering moderate resolution.

- Spot Size: 0.5-3 mm, balancing precision and speed.

- Powder Particle Size: 20-150 µm, affecting flowability.

LENS achieves 98-99% density, with surface roughness (Ra 15-30 µm) requiring post-processing.

Materials and Applications

Materials include titanium, Inconel, and stainless steel, used in aerospace for repairs, medical for implants, and tooling for wear-resistant coatings.

Selective Laser Sintering (SLS) for Metals

SLS for metals, similar to DMLS, sinters metal powder using a laser, but is less common due to lower density compared to SLM.

Process and Parameters

A laser sinters a powder bed (20-50 µm) in an inert atmosphere. Parameters include:

- Laser Power: 200-400 W, optimized for sintering.

- Scan Speed: 500-1200 mm/s, ensuring bonding.

- Layer Thickness: 20-50 µm, similar to DMLS.

- Powder Particle Size: 15-45 µm, for uniform sintering.

Parts achieve 95-98% density, with surface roughness (Ra 10-20 µm) requiring finishing.

Materials and Applications

Materials include stainless steel and aluminum, used in prototyping and non-critical automotive parts.

Metal Fused Filament Fabrication (Metal FFF)

Metal FFF extrudes a metal-polymer filament, followed by debinding and sintering, offering a cost-effective alternative for small parts.

Process and Parameters

A filament (metal powder mixed with polymer) is extruded, forming a green part, then debound and sintered (1200-1400°C). Parameters include:

- Nozzle Diameter: 0.4-0.8 mm, affecting resolution.

- Layer Thickness: 50-200 µm, balancing speed and detail.

- Sintering Temperature: 1200-1400°C, material-dependent.

- Print Speed: 20-50 mm/s, slower than powder bed methods.

Parts achieve 95-97% density with 15-20% shrinkage, and surface roughness (Ra 10-20 µm) may require polishing.

Materials and Applications

Materials include stainless steel and tool steel, used in prototyping, small tools, and educational applications.

Electron Beam Freeform Fabrication (EBF3)

EBF3, a DED variant, uses an electron beam to melt metal wire in a vacuum, ideal for large aerospace parts.

Process and Parameters

A wire feedstock is melted by an electron beam and deposited layer by layer. Parameters include:

- Beam Power: 3-10 kW, enabling high deposition rates.

- Deposition Rate: 1-7 kg/h, faster than LENS.

- Layer Thickness: 1-3 mm, coarser than powder methods.

- Wire Diameter: 1-3 mm, affecting build speed.

Parts achieve 98-99% density, with rough surfaces (Ra 30-50 µm) requiring machining.

Materials and Applications

Materials include titanium and aluminum, used in aerospace for large structural components.

Plasma Arc Welding-based 3D Printing

This DED method uses a plasma arc to melt metal wire or powder, suitable for large-scale industrial applications.

Process and Parameters

A plasma arc melts feedstock, deposited via a nozzle. Parameters include:

- Arc Power: 10-30 kW, enabling high deposition.

- Deposition Rate: 2-10 kg/h, among the highest.

- Layer Thickness: 1-5 mm, for large parts.

- Feedstock Type: Wire (1-4 mm) or powder (50-150 µm).

Parts achieve 97-99% density, with very rough surfaces (Ra 40-60 µm).

Materials and Applications

Materials include steel and titanium, used in heavy industry for structural components and repairs.

Ultrasonic Additive Manufacturing (UAM)

UAM bonds thin metal foils using ultrasonic vibrations, followed by CNC machining for precision, ideal for dissimilar metal parts.

Process and Parameters

Metal foils (50-150 µm) are welded using ultrasonic vibrations (20 kHz), with machining to shape parts. Parameters include:

- Ultrasonic Frequency: 20 kHz, for bonding.

- Foil Thickness: 50-150 µm, determining resolution.

- Welding Pressure: 5-10 kN, ensuring strong bonds.

- Print Speed: 10-30 mm/s, slower due to machining.

Parts achieve near-full density, with excellent bonding but require extensive machining.

Materials and Applications

Materials include aluminum, copper, and titanium, used in aerospace for heat exchangers and electronics for embedded sensors.

Comparison of 3D Metal Printing Technologies

| Technology | Energy Source | Layer Thickness (µm) | Part Density (%) | Common Materials | Applications |

|---|---|---|---|---|---|

| SLM | Laser | 20-100 | 99.5-99.9 | Titanium, Stainless Steel, Inconel | Aerospace, Medical, Tooling |

| DMLS | Laser | 20-50 | 99+ | Stainless Steel, Titanium, Aluminum | Aerospace, Medical, Automotive |

| EBM | Electron Beam | 50-200 | 98-99 | Titanium, Cobalt-Chrome | Medical, Aerospace |

| Binder Jetting | Binder + Furnace | 50-100 | 95-98 | Stainless Steel, Copper | Automotive, Jewelry |

| DED | Laser/Plasma Arc | 250-1000 | 98-99 | Titanium, Stainless Steel | Aerospace, Repairs |

| LENS | Laser | 200-500 | 98-99 | Titanium, Inconel | Aerospace, Medical, Tooling |

| SLS for Metals | Laser | 20-50 | 95-98 | Stainless Steel, Aluminum | Prototyping, Automotive |

| Metal FFF | Extrusion + Furnace | 50-200 | 95-97 | Stainless Steel, Tool Steel | Prototyping, Tooling |

| EBF3 | Electron Beam | 1000-3000 | 98-99 | Titanium, Aluminum | Aerospace Structures |

| Plasma Arc Welding | Plasma Arc | 1000-5000 | 97-99 | Steel, Titanium | Heavy Industry, Repairs |

| UAM | Ultrasonic Vibrations | 50-150 | Near 100 | Aluminum, Copper, Titanium | Aerospace, Electronics |

Key Considerations in 3D Metal Printing

Choosing a 3D metal printing technology depends on application requirements, material compatibility, and production goals. Key factors include:

Material Compatibility

Material choice affects cost, properties, and process suitability. Titanium is lightweight but costly, while stainless steel is affordable and corrosion-resistant.

Part Complexity and Size

SLM and DMLS excel for intricate, small parts; DED, EBF3, and Plasma Arc suit large components; UAM is ideal for dissimilar metal bonding.

Production Volume

Binder Jetting and Metal FFF are cost-effective for medium volumes, while SLM, EBM, and DMLS suit low-volume, high-precision parts. DED and EBF3 are better for one-offs or repairs.

Post-Processing Needs

Most technologies require machining or polishing. Binder Jetting and Metal FFF involve debinding and sintering, while UAM requires extensive CNC machining.

Conclusion

The eleven 3D metal printing technologies—SLM, DMLS, EBM, Binder Jetting, DED, LENS, SLS for Metals, Metal FFF, EBF3, Plasma Arc Welding, and UAM—offer diverse capabilities for producing complex metal parts. Each has unique processes, parameters, and applications, enabling manufacturers to select the most suitable method for their specific needs in industries ranging from aerospace to medical and beyond.