3D plastic printing, a subset of additive manufacturing, builds parts layer by layer using various plastic materials. Each technology offers distinct advantages, material compatibility, and applications, making it critical to understand their differences for specific use cases. This article details 13 key 3D plastic printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Processing (DLP), Material Jetting (MJ), PolyJet, Multi Jet Fusion (MJF), Selective Laser Sintering (SLS), Continuous Liquid Interface Production (CLIP), Vat Photopolymerization, Powder Bed Fusion, Binder Jetting, Sheet Lamination, and Directed Energy Deposition. Below, each method is explored with technical specifications, materials, applications, and limitations.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), extrudes thermoplastic filament through a heated nozzle to build parts layer by layer. It is widely used due to its affordability and versatility.

Operating Principles: A thermoplastic filament is melted at 190°C–300°C and deposited via a nozzle moving in X and Y directions. The build platform lowers in the Z direction per layer (50–400 microns). Cooling solidifies the material.

Materials: Common materials include PLA (biodegradable, easy to print), ABS (durable, heat-resistant up to 80°C), PETG (strong, flexible), and high-performance polymers like Polycarbonate (PC) and Nylon.

| Parameter | Value |

|---|---|

| Layer Thickness | 50–400 microns |

| Extruder Temperature | 190–300°C |

| Build Volume | 200 x 200 x 200 mm (consumer) to 1000 x 1000 x 1000 mm (industrial) |

| Print Speed | 20–150 mm/s |

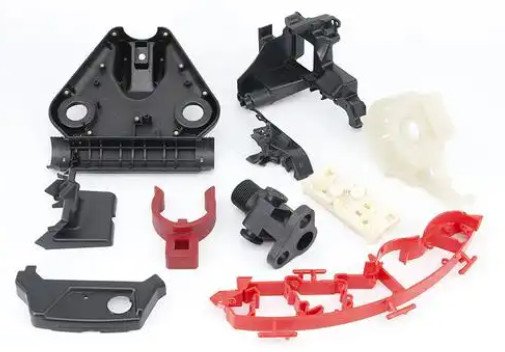

Applications: FDM is used for prototyping, jigs, fixtures, and low-cost consumer goods like toys. It is common in education, automotive, and aerospace for functional prototypes.

Limitations: Lower resolution results in visible layer lines, requiring post-processing. Support structures complicate complex geometries, and parts are anisotropic, weaker along the Z-axis.

Stereolithography (SLA)

Stereolithography (SLA) uses a UV laser to cure liquid photopolymer resin, producing high-resolution parts with smooth surfaces.

Operating Principles: A laser cures resin in a vat, solidifying it layer by layer (25–100 microns). The platform moves upward, and parts are rinsed in isopropyl alcohol and UV-cured post-printing.

Materials: SLA resins include standard (ABS-like), engineering (tough, heat-resistant up to 120°C), and biocompatible options for medical use.

Applications: SLA is ideal for jewelry molds, dental restorations, and microfluidic devices in medical and aerospace sectors.

Limitations: Resins are brittle, limiting high-impact use. Support structures and resin handling increase complexity and cost.

Digital Light Processing (DLP)

Digital Light Processing (DLP) uses a digital projector to cure photopolymer resin, similar to SLA but faster due to curing entire layers at once.

Operating Principles: A projector flashes UV light through a digital micromirror device to cure resin layers (25–100 microns). The platform moves upward, and parts require rinsing and UV curing.

Materials: DLP uses similar resins to SLA, including standard, engineering, and biocompatible varieties.

Applications: DLP is used for high-resolution prototypes like dental models, jewelry, and small intricate parts.

Limitations: Like SLA, DLP parts are brittle, and resin handling requires safety measures. Build volumes are often smaller than SLA.

Material Jetting (MJ)

Material Jetting (MJ) jets photopolymer droplets onto a platform, curing them with UV light to create high-precision parts, often with multiple materials.

Operating Principles: Inkjet heads deposit resin droplets (16–30 microns), cured instantly by UV light. Multiple materials can be jetted simultaneously.

Materials: MJ uses rigid, flexible, and transparent photopolymers, including ABS-like and elastomeric resins.

Applications: MJ is used for multi-material prototypes, such as overmolded parts and medical models.

Limitations: Parts are less durable, and support material removal is labor-intensive. MJ systems are expensive.

PolyJet

PolyJet, a type of MJ, jets photopolymers to create multi-material, multi-color parts with excellent surface finishes.

Operating Principles: Multiple nozzles jet resins (16–30 microns), cured by UV light. Support material is jetted and removed via water or peeling.

Materials: PolyJet uses rigid, flexible, transparent, and biocompatible resins, supporting material blends for varying properties.

Applications: PolyJet is used for aesthetic prototypes, overmolded parts, and medical models in consumer electronics and automotive industries.

Limitations: Parts lack durability for end-use, and support removal is time-consuming. Systems are costly.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) uses inkjet arrays to apply fusing and detailing agents to thermoplastic powder, fused by heat, offering speed and isotropy.

Operating Principles: Fusing agents define geometry, detailing agents enhance edges, and heat fuses layers (80–100 microns). Unused powder is recycled.

Materials: MJF uses Nylon 12, Nylon 11, and Polypropylene, with elastomers like TPA for flexibility.

Applications: MJF is used for functional prototypes, low-volume production, and automotive parts like clips and brackets.

Limitations: Limited to industrial printers and nylon-based materials. Post-processing is required for surface finish.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) fuses thermoplastic powder with a laser, creating strong, isotropic parts without supports.

Operating Principles: A laser sinters powder in a heated chamber (160°C–190°C), layer by layer (50–150 microns). Excess powder is removed post-printing.

Materials: SLS uses Nylon 11, Nylon 12, and high-performance polymers like PEEK.

Applications: SLS is used for functional prototypes, ducting systems, and medical components.

Limitations: Expensive industrial systems and rough surface finishes require post-processing.

Continuous Liquid Interface Production (CLIP)

Continuous Liquid Interface Production (CLIP) uses a digital projector and oxygen-permeable membrane to cure resin continuously, offering high speed and smooth finishes.

Operating Principles: UV light cures resin through an oxygen-permeable window, allowing continuous printing (25–100 microns). Parts are rinsed and UV-cured.

Materials: CLIP uses engineering and biocompatible resins, offering toughness and flexibility.

Applications: CLIP is used for dental aligners, medical devices, and consumer goods prototypes.

Limitations: Limited material range and high system costs restrict accessibility.

Vat Photopolymerization

Vat Photopolymerization encompasses SLA, DLP, and CLIP, curing liquid resin in a vat using light sources.

Operating Principles: Light (laser or projector) cures resin layers (25–100 microns). Processes vary by light source and curing method.

Materials: Resins include standard, engineering, and biocompatible types.

Applications: Used for high-precision parts in dental, jewelry, and medical fields.

Limitations: Brittle parts and complex post-processing limit functional use.

Powder Bed Fusion

Powder Bed Fusion includes SLS and MJF, fusing powder with lasers or agents to create isotropic parts.

Operating Principles: Energy sources fuse powder layers (50–150 microns). No supports are needed due to surrounding powder.

Materials: Nylon, Polypropylene, and high-performance polymers like PEEK.

Applications: Functional parts in aerospace, automotive, and medical sectors.

Limitations: High costs and post-processing for surface finish.

Binder Jetting

Binder Jetting deposits a binding agent onto powder to form parts, often used for full-color models or temporary molds.

Operating Principles: A printhead jets binder onto powder layers (50–100 microns), which are later cured or infiltrated.

Materials: Polymers like PMMA and composite powders.

Applications: Full-color prototypes, architectural models, and casting molds.

Limitations: Parts are fragile unless infiltrated, and accuracy is lower than SLS.

Sheet Lamination

Sheet Lamination bonds sheets of plastic material, cutting them to form parts, often for large-scale models.

Operating Principles: Sheets are bonded and cut layer by layer (100–200 microns) using lasers or blades.

Materials: PVC, PET, and other thin plastic sheets.

Applications: Large prototypes, packaging, and visual models.

Limitations: Limited structural integrity and material variety restrict functional use.

Directed Energy Deposition

Directed Energy Deposition (DED) melts plastic powder or wire with a focused energy source, typically for large parts or repairs.

Operating Principles: A laser or electron beam melts material as it is deposited (200–500 microns). Used for plastics and metals.

Materials: Thermoplastics like ABS and Nylon in powder or wire form.

Applications: Large-scale parts, repairs, and hybrid manufacturing in aerospace.

Limitations: Lower resolution and limited plastic material options.

Comparing 3D Plastic Printing Technologies

| Technology | Layer Thickness (microns) | Key Materials | Main Applications |

|---|---|---|---|

| FDM | 50–400 | PLA, ABS, PETG, PC | Prototyping, jigs, consumer goods |

| SLA/DLP/CLIP | 25–100 | Photopolymer resins | Dental, jewelry, medical models |

| MJ/PolyJet | 16–30 | Photopolymers | Multi-material prototypes |

| SLS/MJF | 50–150 | Nylon, PP | Functional parts, low-volume production |

| Binder Jetting | 50–100 | PMMA, composites | Full-color models, molds |

| Sheet Lamination | 100–200 | PVC, PET | Large prototypes, packaging |

| DED | 200–500 | ABS, Nylon | Large parts, repairs |

Each technology serves specific needs based on resolution, material, and cost. FDM is cost-effective but less precise, while SLA, DLP, and CLIP excel in detail. SLS and MJF offer strong parts, MJ and PolyJet provide multi-material flexibility, and Binder Jetting suits visual models. Sheet Lamination and DED are niche for large-scale or repair applications. Understanding these technologies ensures optimal selection for project requirements.