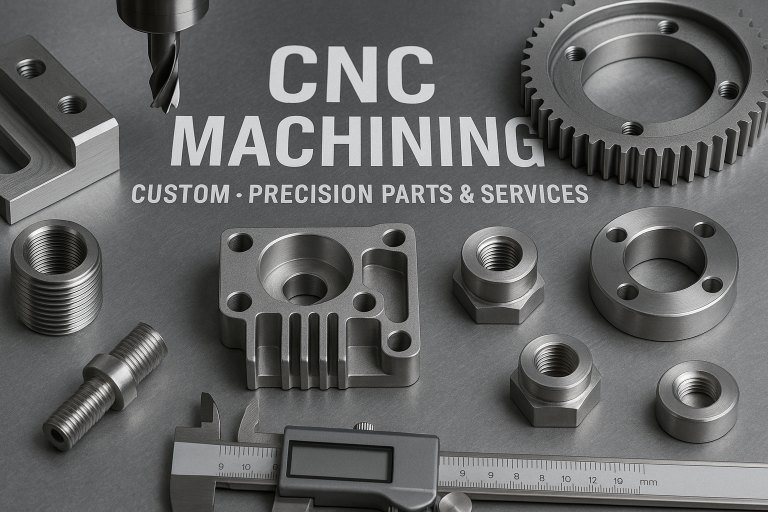

CNC machining custom services have become a cornerstone in modern manufacturing, offering unparalleled precision and flexibility for creating tailored components across various industries. Whether you are in aerospace, automotive, medical, or any other sector requiring high-quality parts, custom CNC machining provides the ability to produce complex geometries with tight tolerances. This comprehensive guide explores the intricacies of custom CNC machining, detailing its processes, materials, applications, and benefits to help you make informed decisions for your projects.

With a focus on technical expertise and systematic approaches, this article aims to provide a deep dive into the world of CNC machining custom services. From understanding the fundamental processes to exploring specific parameters and capabilities, we cover all essential aspects to showcase the value of partnering with a reliable CNC machining provider.

Understanding CNC Machining Custom Services

Custom CNC machining refers to the process of using computer numerical control (CNC) machines to create parts and components tailored to specific designs and requirements. Unlike standard machining, custom CNC machining focuses on producing unique, often one-of-a-kind parts that meet precise specifications provided by the client. This process leverages advanced software and machinery to ensure accuracy, repeatability, and efficiency in manufacturing.

The core of CNC machining lies in its ability to automate the control of machining tools through pre-programmed computer software. This automation allows for the production of intricate shapes and designs that would be challenging or impossible to achieve with manual machining. Custom CNC machining services typically include milling, turning, drilling, and grinding, each serving a specific purpose in shaping raw materials into finished products.

Key parameters in custom CNC machining include tolerances as tight as ±0.001 inches (0.0254 mm), surface finishes ranging from 8 to 125 microinches (Ra 0.2 to 3.2 micrometers), and the ability to work with a wide range of materials, from metals like aluminum and stainless steel to plastics like ABS and PEEK. These specifications ensure that the final product meets the exact needs of the client, whether for prototyping or full-scale production.

Materials Used in Custom CNC Machining

One of the significant advantages of custom CNC machining is its versatility in handling a diverse array of materials. The choice of material depends on the application, desired properties, and environmental factors the part will be exposed to. Below, we detail some of the most commonly used materials in custom CNC machining, along with their properties and typical applications.

| Material | Properties | Common Applications |

|---|---|---|

| Aluminum (6061, 7075) | Lightweight, corrosion-resistant, high strength-to-weight ratio | Aerospace components, automotive parts, enclosures |

| Stainless Steel (304, 316) | High strength, excellent corrosion resistance | Medical devices, food processing equipment, marine parts |

| Brass (C360) | Good machinability, corrosion resistance, aesthetic appeal | Fittings, valves, decorative components |

| Plastics (ABS, PEEK) | Lightweight, chemical resistance, insulating properties | Electronic housings, medical implants, prototypes |

Selecting the right material is critical in custom CNC machining, as it directly impacts the part’s performance, durability, and cost. Machinists often collaborate with clients to determine the best material based on factors such as mechanical stress, thermal exposure, and budget constraints. Additionally, custom CNC machining can accommodate exotic materials like titanium and Inconel for specialized applications requiring exceptional strength or heat resistance.

Key Processes in Custom CNC Machining

Custom CNC machining encompasses several processes, each designed to achieve specific outcomes in part production. Understanding these processes helps in selecting the right technique for a given project. Below are the primary methods used in custom CNC machining:

CNC Milling

CNC milling involves using rotary cutters to remove material from a workpiece, creating complex shapes and features. This process is ideal for producing slots, holes, and intricate 3D geometries. Modern CNC milling machines can operate on 3, 4, or 5 axes, with 5-axis milling offering the highest level of precision for complex parts. Typical tolerances for CNC milling are ±0.002 inches (0.0508 mm), ensuring high accuracy for custom components.

CNC Turning

CNC turning, performed on a lathe, rotates the workpiece while a cutting tool shapes it into cylindrical or conical forms. This process is commonly used for creating shafts, pins, and other symmetrical parts. CNC turning can achieve surface finishes as fine as 16 microinches (Ra 0.4 micrometers) and tolerances of ±0.001 inches (0.0254 mm), making it suitable for high-precision applications.

CNC Drilling and Grinding

CNC drilling creates precise holes in a workpiece, often as a secondary operation after milling or turning. CNC grinding, on the other hand, is used to achieve ultra-smooth surface finishes or to refine dimensions to extremely tight tolerances, sometimes as low as ±0.0002 inches (0.005 mm). These processes are critical for parts requiring high levels of accuracy and surface quality.

Applications of Custom CNC Machining

Custom CNC machining serves a wide range of industries, providing solutions for both prototyping and production runs. Its ability to produce parts with exact specifications makes it indispensable in sectors where precision and reliability are paramount. Some notable applications include:

- Aerospace: Manufacturing lightweight, high-strength components such as turbine blades, brackets, and structural parts with tolerances as tight as ±0.0005 inches (0.0127 mm).

- Automotive: Producing engine components, transmission parts, and custom fittings that withstand high stress and temperature variations.

- Medical: Creating surgical instruments, implants, and diagnostic equipment parts from biocompatible materials like titanium and PEEK.

- Electronics: Fabricating enclosures, connectors, and heat sinks with precise dimensions to ensure proper fit and functionality.

These applications highlight the adaptability of custom CNC machining in meeting diverse industry needs. Whether for small-batch prototyping or large-scale production, CNC machining offers consistent quality and repeatability, ensuring that every part meets the required standards.

Benefits of Choosing Custom CNC Machining Services

Opting for custom CNC machining services provides numerous advantages, particularly when compared to traditional manufacturing methods. These benefits are rooted in the technology’s precision, flexibility, and efficiency, making it a preferred choice for many businesses. Below are some of the key benefits:

- High Precision and Accuracy: CNC machines can achieve tolerances as tight as ±0.001 inches (0.0254 mm), ensuring that parts meet exact specifications.

- Flexibility in Design: Custom CNC machining allows for the production of complex geometries and intricate designs that are difficult to achieve with manual methods.

- Material Versatility: The ability to work with a wide range of materials, from metals to plastics, ensures that the right material is used for every application.

- Consistency and Repeatability: Once a design is programmed, CNC machines can produce identical parts with minimal variation, even in high-volume runs.

- Reduced Lead Times: Automation and advanced software streamline the production process, reducing turnaround times for custom orders.

These benefits make custom CNC machining an ideal solution for businesses looking to produce high-quality parts efficiently. By leveraging the capabilities of CNC technology, companies can achieve superior results while maintaining cost-effectiveness.

Factors to Consider When Selecting a CNC Machining Provider

Choosing the right custom CNC machining provider is crucial to the success of your project. Several factors should be evaluated to ensure that the provider can meet your specific needs and deliver high-quality results. These include:

- Experience and Expertise: Look for providers with a proven track record in custom CNC machining, particularly in your industry or with similar projects.

- Equipment and Technology: Ensure the provider uses modern CNC machines with multi-axis capabilities and advanced software for design and programming.

- Quality Assurance: Check for certifications such as ISO 9001, which indicate a commitment to quality control and consistent manufacturing standards.

- Material Capabilities: Verify that the provider can work with the materials required for your project, including any specialized or exotic materials.

- Turnaround Time and Capacity: Assess the provider’s ability to meet your deadlines and handle the volume of parts you need, whether for prototyping or production.

By carefully evaluating these factors, you can partner with a CNC machining provider that aligns with your project goals and delivers components that meet your expectations in terms of quality, precision, and timeliness.

Conclusion

Custom CNC machining is a powerful manufacturing solution that offers unmatched precision, versatility, and efficiency for producing tailored components. From understanding the core processes and materials to recognizing its wide-ranging applications and benefits, this guide has provided a comprehensive overview of what custom CNC machining entails. By partnering with a skilled provider and considering critical selection factors, businesses can leverage this technology to achieve high-quality results for their unique needs.

Whether you require intricate parts for aerospace applications or robust components for automotive systems, custom CNC machining delivers the accuracy and reliability necessary to bring your designs to life. With detailed parameters and a focus on technical excellence, this approach ensures that every project is executed with the highest standards of quality and precision.