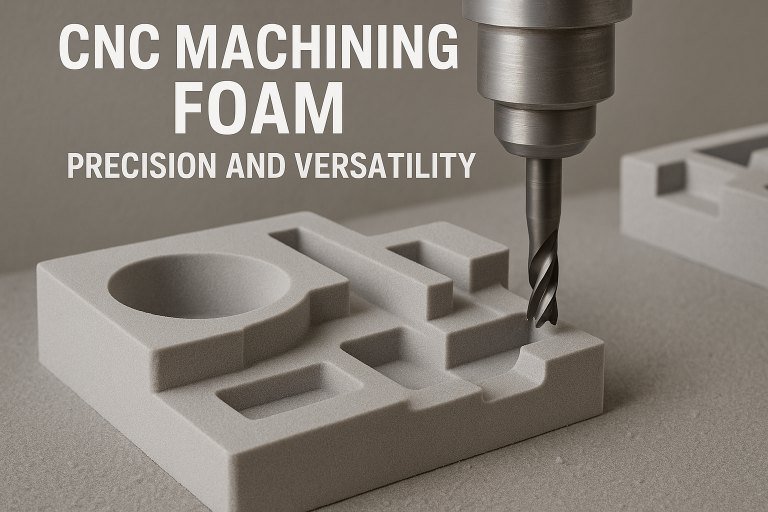

CNC machining foam is a specialized process that leverages computer numerical control (CNC) technology to cut, shape, and create intricate designs from various types of foam materials. This technique is widely used across industries for prototyping, packaging, insulation, and even artistic applications. In this detailed guide, we will explore the intricacies of CNC machining foam, including the materials used, the equipment involved, the step-by-step process, and the diverse applications of this technology. Whether you're a manufacturer, designer, or hobbyist, understanding the technical aspects of CNC foam machining can help you achieve precise and high-quality results.

Understanding Foam Materials for CNC Machining

Foam materials come in a variety of types, each with unique properties that make them suitable for specific applications in CNC machining. The choice of foam directly impacts the machining process, the tools required, and the final product's performance. Below are some of the most commonly used foam materials in CNC machining:

- Polyurethane Foam: Known for its durability and flexibility, polyurethane foam is often used in cushioning, packaging, and insulation. It can be easily machined into complex shapes with a density range of 2 to 40 pounds per cubic foot (PCF).

- Expanded Polystyrene (EPS) Foam: Lightweight and cost-effective, EPS foam is widely used for packaging and prototyping. Its density typically ranges from 1 to 3 PCF, making it easy to cut with CNC routers.

- Polyethylene Foam: This foam offers excellent shock absorption and chemical resistance, making it ideal for protective packaging. It has a density range of 1.5 to 9 PCF and requires specific cutting tools for precision.

- EVA Foam: Ethylene-vinyl acetate (EVA) foam is popular in cosplay, crafts, and padding due to its soft texture and flexibility. Its density usually falls between 2 and 12 PCF.

Selecting the right foam material depends on factors such as the intended application, required durability, and environmental conditions. CNC machining allows for precise customization of these materials to meet exact specifications, ensuring minimal waste and optimal results.

Equipment and Tools for CNC Machining Foam

The success of CNC machining foam relies heavily on the equipment and tools used. Unlike machining harder materials like metal or wood, foam requires specialized setups to avoid tearing, melting, or deformation. Here are the key components involved:

- CNC Routers: These are the most common machines for foam machining, offering high-speed spindles and large working areas. A typical CNC router for foam operates at spindle speeds of 10,000 to 24,000 RPM.

- Hot Wire Cutters: For certain foams like EPS, hot wire CNC machines use heated wires to melt through the material, creating clean edges. Wire temperatures often range from 200°C to 500°C depending on foam density.

- End Mills and Bits: Specialized foam-cutting bits, such as ball nose or straight flute end mills, are used to prevent material buildup. These tools often have diameters ranging from 1/8 inch to 1/2 inch for detailed work.

- Vacuum Tables: To secure foam during machining, vacuum tables are used to hold the material in place without clamps, ensuring precision and avoiding surface damage.

The choice of equipment depends on the foam type, project complexity, and desired finish. Proper tool selection and machine calibration are critical to achieving smooth cuts and intricate designs without compromising the foam’s structural integrity.

The CNC Machining Process for Foam

CNC machining foam involves a systematic process that ensures precision and efficiency. Below is a detailed breakdown of the steps involved in transforming raw foam into a finished product:

- Design Creation: The process begins with creating a digital design using CAD (Computer-Aided Design) software. The design includes precise measurements, often with tolerances as tight as ±0.005 inches for high-precision applications.

- Material Selection and Preparation: The appropriate foam material is chosen based on the project requirements. The foam is then cut to a rough size and secured onto the CNC machine’s work surface.

- Toolpath Programming: Using CAM (Computer-Aided Manufacturing) software, the design is converted into a toolpath that guides the CNC machine. Parameters such as cutting speed (typically 100 to 500 inches per minute for foam) and depth of cut are set.

- Machining: The CNC machine executes the programmed toolpath, cutting or shaping the foam with precision. For intricate designs, multiple passes at depths of 0.1 to 0.5 inches per pass may be required to avoid material stress.

- Finishing: After machining, the foam part may undergo secondary processes such as sanding, coating, or assembly to achieve the desired final appearance and functionality.

Each step in this process is critical to ensuring that the final foam product meets the design specifications. Proper setup and monitoring during machining prevent issues like uneven cuts or tool damage, especially when working with delicate foam materials.

Applications of CNC Machined Foam

CNC machining foam is utilized in a wide range of industries due to its versatility and ability to produce custom shapes with high precision. Below are some key applications where this technology excels:

- Packaging: Custom foam inserts for electronics, medical devices, and fragile goods are created using CNC machining to ensure perfect fit and protection. Foam densities of 2 to 6 PCF are commonly used for such applications.

- Prototyping: Designers and engineers use CNC machined foam to create prototypes for product testing before moving to more expensive materials. This allows for rapid iteration with minimal cost.

- Insulation: Foam panels and shapes are machined for thermal and acoustic insulation in construction and automotive industries, often using materials with thermal conductivity values of 0.02 to 0.05 W/m·K.

- Art and Craft: Artists and hobbyists use CNC machining to create detailed sculptures, props, and cosplay components from EVA and polyurethane foams for lightweight yet durable designs.

These applications highlight the adaptability of CNC machining foam across both industrial and creative fields. The ability to produce complex geometries and custom solutions makes this technology indispensable for modern manufacturing and design.

Technical Parameters for Optimal Foam Machining

Achieving high-quality results in CNC machining foam requires careful attention to technical parameters. The following table outlines key settings and considerations for machining different types of foam materials:

| Foam Type | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (Inches) | Recommended Tool |

|---|---|---|---|---|

| Polyurethane Foam | 12,000 - 18,000 | 200 - 400 | 0.2 - 0.5 | Ball Nose End Mill |

| Expanded Polystyrene (EPS) | 10,000 - 15,000 | 100 - 300 | 0.1 - 0.3 | Hot Wire or Straight Bit |

| Polyethylene Foam | 15,000 - 20,000 | 250 - 500 | 0.2 - 0.4 | Straight Flute Bit |

| EVA Foam | 12,000 - 16,000 | 150 - 350 | 0.1 - 0.3 | Ball Nose or Spiral Bit |

These parameters serve as a starting point and may need adjustment based on the specific CNC machine, foam thickness, and project complexity. Monitoring the machining process and making real-time adjustments can prevent issues like overheating or material deformation.

Benefits of CNC Machining Foam

CNC machining offers several advantages when working with foam materials, making it a preferred method for many applications. Here are some of the key benefits:

- Precision: CNC machines can achieve tolerances as tight as ±0.005 inches, ensuring consistent and accurate cuts even for intricate designs.

- Efficiency: Automated machining reduces production time, with complex parts often completed in minutes compared to hours with manual methods.

- Versatility: CNC technology can handle a wide range of foam types and densities, accommodating diverse project requirements.

- Minimal Waste: Optimized toolpaths and precise cutting minimize material waste, reducing costs and environmental impact.

These benefits make CNC machining foam an ideal solution for both small-scale projects and large-scale industrial production, delivering high-quality results with repeatability and reliability.