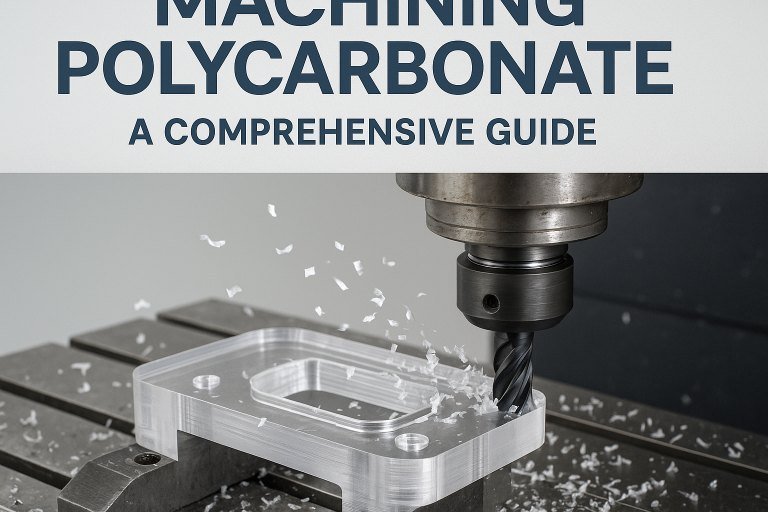

Polycarbonate is a versatile, durable thermoplastic widely used in industries such as automotive, aerospace, medical, and electronics due to its exceptional strength, transparency, and impact resistance. However, machining polycarbonate requires specific techniques and considerations to achieve high-quality results without compromising the material's integrity. This guide provides a detailed, technical overview of machining polycarbonate, covering tools, parameters, processes, and best practices to ensure precision and efficiency. Whether you're a professional machinist or a hobbyist, this resource aims to equip you with the knowledge needed for successful polycarbonate fabrication.

Understanding Polycarbonate Properties

Before diving into the machining process, it is essential to understand the inherent properties of polycarbonate that affect how it behaves under cutting and shaping operations. Polycarbonate is a lightweight material with a density of approximately 1.20 g/cm³, offering a tensile strength of about 55-75 MPa and a high impact resistance that surpasses many other plastics. Its glass transition temperature is around 147°C, which means it can soften under excessive heat during machining, leading to potential deformation or melting.

Additionally, polycarbonate is prone to stress cracking when exposed to certain chemicals or excessive mechanical stress. Its transparency, with a light transmission of up to 90%, also demands careful handling to avoid scratches or surface damage during machining. Understanding these properties helps in selecting the right tools, speeds, and feeds to prevent issues like cracking, melting, or poor surface finish.

Tools and Equipment for Machining Polycarbonate

The choice of tools is critical when machining polycarbonate to ensure clean cuts and precise results. Standard tools used for metals or harder plastics may not be suitable due to polycarbonate’s softer and more flexible nature. Here are the primary tools and equipment recommended:

- Carbide Tools: Carbide end mills, drills, and turning tools are preferred due to their sharpness and durability. They provide cleaner cuts compared to high-speed steel (HSS) tools, reducing the risk of material melting.

- Sharp Cutting Edges: Tools with sharp, polished edges minimize friction and heat buildup. A rake angle of 0° to 5° and a clearance angle of 5° to 10° are ideal for most operations.

- CNC Machines: Computer Numerical Control (CNC) machines offer precision and consistency, especially for complex shapes or high-volume production. They allow fine control over speed and feed rates.

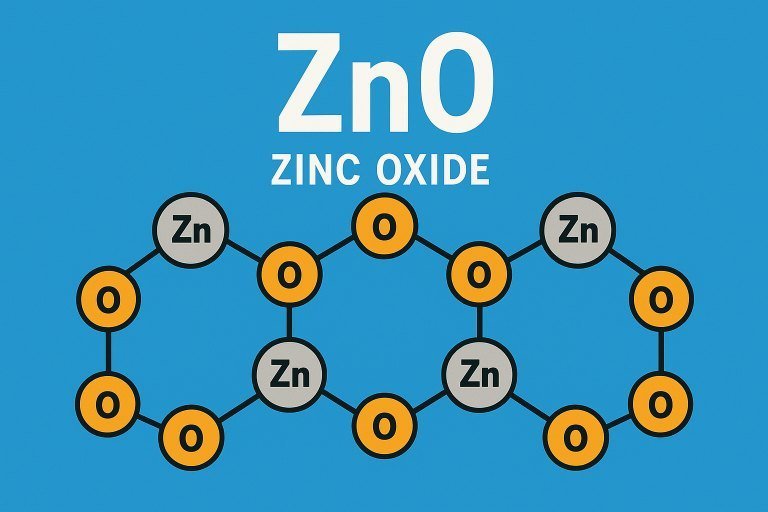

- Coolants: Water-based coolants or compressed air are often used to dissipate heat during machining, preventing thermal deformation of the polycarbonate.

Using tools with the correct geometry and maintaining their sharpness through regular inspection is vital for achieving a high-quality finish and prolonging tool life.

Key Machining Parameters for Polycarbonate

Machining polycarbonate requires careful adjustment of parameters such as speed, feed rate, and depth of cut to avoid overheating or material damage. Below are the recommended parameters for common machining operations:

| Operation | Spindle Speed (RPM) | Feed Rate (mm/min) | Depth of Cut (mm) |

|---|---|---|---|

| Milling | 8,000 - 12,000 | 500 - 1,000 | 0.5 - 2.0 |

| Turning | 1,000 - 3,000 | 100 - 300 | 0.1 - 1.0 |

| Drilling | 1,500 - 3,000 | 50 - 150 | 0.2 - 0.5 per pass |

These parameters serve as a starting point and may need adjustment based on the specific machine, tool condition, and polycarbonate grade (e.g., UV-stabilized or flame-retardant variants). Monitoring the process for signs of excessive heat, such as a burnt smell or visible melting, is crucial. Reducing spindle speed or increasing coolant flow can help mitigate such issues.

Common Machining Techniques for Polycarbonate

Several machining techniques can be applied to polycarbonate, each suited to different shapes, sizes, and applications. Below are the most commonly used methods, along with specific considerations for each:

Milling Polycarbonate

Milling is widely used for creating slots, pockets, and complex geometries in polycarbonate. High-speed milling with carbide end mills is recommended, using climb milling to reduce the risk of chipping. A low depth of cut and moderate feed rate help maintain a smooth surface finish. It’s also important to secure the workpiece firmly to prevent vibration, which can cause inaccuracies or surface defects.

Turning Polycarbonate

Turning is ideal for producing cylindrical or conical shapes. Use a sharp carbide insert with a small nose radius to minimize heat generation. Continuous cuts at a steady speed ensure uniform results, while intermittent cuts should be avoided as they can lead to uneven stress distribution and potential cracking.

Drilling Polycarbonate

Drilling requires special attention to avoid cracking or chipping around the hole. Use a drill bit with a point angle of 60° to 90° and ensure a slow feed rate to prevent heat buildup. Backing the material with a sacrificial layer (like wood or acrylic) during drilling can help prevent exit burrs and ensure a clean hole.

Cutting and Sawing Polycarbonate

For straight cuts or rough shaping, band saws or circular saws with fine-toothed blades are effective. Blades with 10-12 teeth per inch are ideal to minimize chipping. Keeping the blade cool with air or a lubricant during cutting prevents melting of the material along the cut line.

Finishing and Post-Processing Techniques

After machining, polycarbonate often requires finishing to achieve the desired surface quality or to remove minor imperfections. Polishing is a common method to restore transparency or improve aesthetics. Flame polishing, using a controlled propane torch, can smooth edges, but it must be done cautiously to avoid overheating. Alternatively, mechanical polishing with progressively finer abrasives (from 400 to 1200 grit) followed by a buffing compound can achieve a high-gloss finish.

Solvent polishing is another option, using chemicals like methylene chloride to smooth surfaces, but it requires proper ventilation and safety precautions due to the toxicity of the solvent. Additionally, deburring edges with a scraper or fine sandpaper helps remove sharp remnants from machining, ensuring safety and a professional appearance.

Safety Considerations in Machining Polycarbonate

Safety is paramount when machining polycarbonate due to the risks of heat generation, dust, and chemical exposure during certain processes. Always wear protective gear, including safety glasses, gloves, and a dust mask, to shield against flying chips and fine particles. Ensure adequate ventilation in the workspace, especially if using coolants or solvents for polishing.

Polycarbonate dust can be hazardous if inhaled, so using a dust extraction system or vacuum during machining is highly recommended. Avoid direct contact with hot tools or workpieces to prevent burns, and store polycarbonate sheets or parts away from heat sources to prevent unintended deformation.

Applications of Machined Polycarbonate Parts

Machined polycarbonate components are used across a wide range of industries due to their unique combination of strength, clarity, and lightweight properties. In the automotive sector, polycarbonate is machined into headlight lenses, interior panels, and protective covers. In the medical field, it is used for equipment housings, face shields, and sterile barriers due to its biocompatibility and ease of sterilization.

The electronics industry relies on polycarbonate for insulating components, display screens, and protective enclosures. Additionally, in construction and architecture, machined polycarbonate is used for glazing, skylights, and safety barriers, capitalizing on its impact resistance and optical clarity. Understanding the end-use of the part often dictates the machining approach, such as prioritizing surface finish for optical applications or dimensional accuracy for structural components.

Troubleshooting Common Machining Issues

While machining polycarbonate is generally straightforward with the right approach, certain issues can arise if parameters or techniques are not optimized. Melting is a frequent problem caused by excessive heat, often due to high spindle speeds or dull tools. Reducing speed, increasing coolant use, or sharpening tools can resolve this. Cracking may occur from excessive clamping pressure or improper drilling techniques; using lower pressure and backing material can help.

Poor surface finish, characterized by scratches or roughness, often results from vibration or incorrect feed rates. Securing the workpiece and adjusting the feed rate to a moderate level typically improves the outcome. By systematically addressing these issues, machinists can achieve consistent, high-quality results with polycarbonate.